In today’s competitive oral care market, product quality is no longer just a technical matter — it’s a business survival issue. The brush head, often seen as a small component, plays a crucial role in customer satisfaction and safety. Recently, several toothbrush manufacturers have issued warnings to brand owners: it’s time to stop using brush heads that fail to meet modern performance and safety standards. Whether you’re managing a new DTC oral care brand or a private-label OEM line, reviewing your brush head supplier could be the key step to protect your brand.

Not all brush heads are created equal. Outdated models—especially those using recycled plastics, poor bristle alignment, or untested adhesives—can cause more harm than good.

Brands continuing to use these designs face significant risks, including:

Brush heads loosening during use

Excessive bristle shedding

Irritation due to rough or uneven bristles

Compatibility issues with electric handles

These quality problems not only frustrate consumers but also represent serious OEM risk control failures. Once negative reviews or returns pile up, the damage to your brand image can be lasting and costly.

According to leading OEM manufacturers, brands should immediately stop using brush heads that:

Use low-density or inconsistent bristles

Contain metal wire inside the core (non-FDA compliant)

Fail 200+ cycle durability tests

Are made without ISO-certified materials

Such brush heads might appear affordable upfront, but they carry hidden quality and liability risks. The top manufacturer advice is clear: work only with factories that can prove their quality control systems and compliance documentation.

Quality starts with transparency. To strengthen OEM risk control, brands should:

Request detailed material and compliance reports from suppliers.

Perform third-party testing for mechanical strength and hygiene.

Inspect mold precision and bristle uniformity before mass production.

Maintain documentation for CE, FDA, or ISO certification.

A trustworthy manufacturer won’t hesitate to share these reports — and often helps clients redesign older brush heads to meet current standards.

To truly protect your brand, choose a manufacturer that doesn’t just produce brush heads, but partners with you in product development and compliance.

Ideal manufacturers offer:

Medical-grade nylon or Dupont bristles

Metal-free core structures

Fully automated assembly lines for consistency

End-to-end traceability for every production batch

Partnering with a professional OEM means you don’t just reduce product risks — you also build consumer confidence and long-term loyalty.

The oral care market is moving fast. Brands that ignore manufacturing warnings risk falling behind — or worse, facing product recalls.

By implementing strong OEM risk control and following manufacturer advice, you can stop using brush heads that endanger your reputation and ensure every product leaving your line represents your commitment to safety and excellence.

Electric Toothbrush Precision Mold Shell Manufacturing: How to Balance Aesthetics and Durability?

.jpg)

Electric Toothbrush Noise Levels Compared: Find a Quiet Brush for Light Sleepers

.jpg)

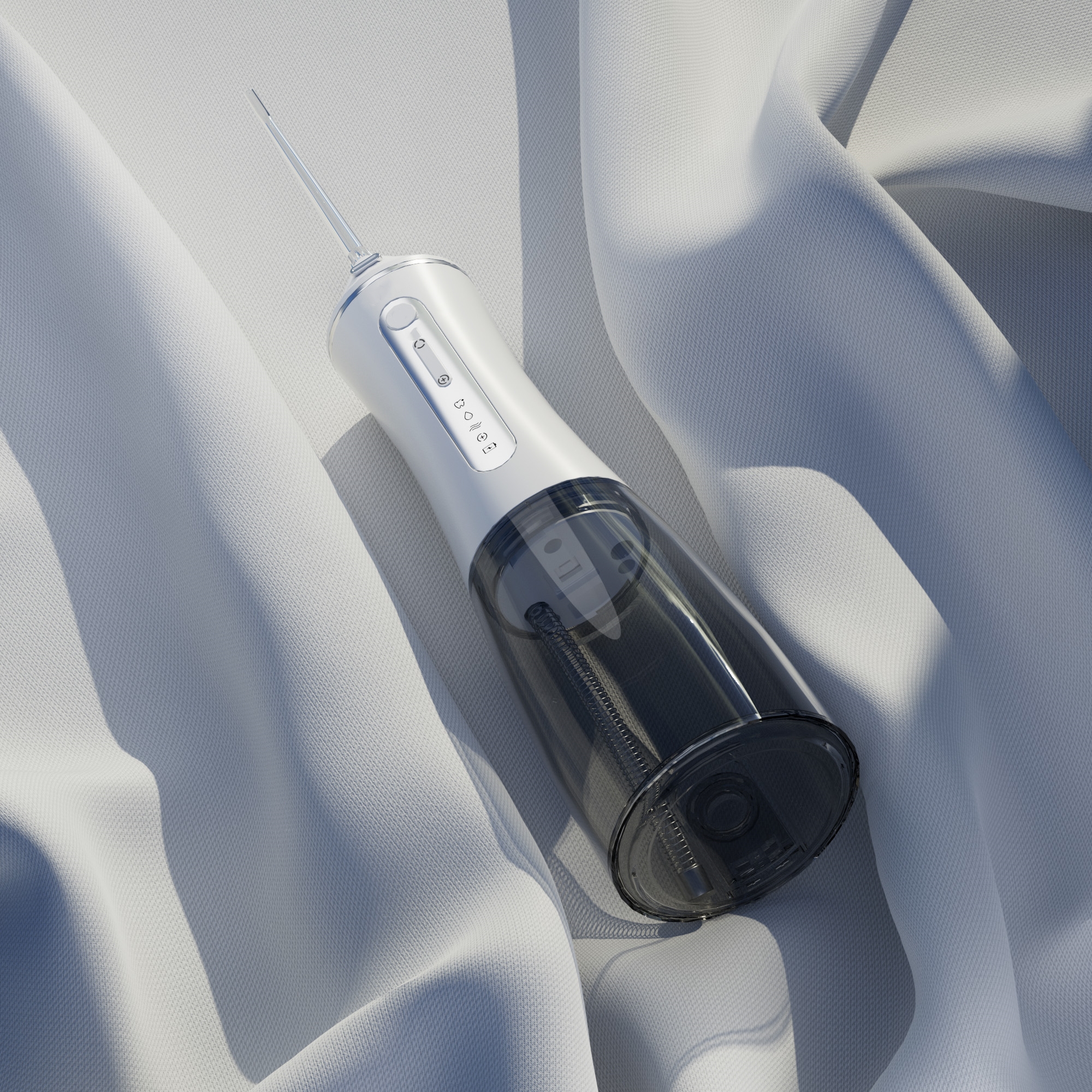

Water Flosser Gearbox Assembly & Drop Test: Ensuring Reliability and Durability

Travel Water Flosser Design: Power Compatibility, Storage & Waterproofing

Effect of UVC Sterilization in Oral Care Products

Can an IPX7 Waterproof rating let you enjoy brushing in the Safe Shower Use?

Market Trends and Competitiveness of Electric Toothbrushes

Is an IPX8 Waterproof Rating Essential for Durable Brush Heads?

Seeking Custom Handle Design Services Within Your OEM/ODM Manufacturing Partnership?

How to choose a reliable teeth whitening kit manufacturer

.jpg)

Smart Toothbrush B2B Solutions for Global Distributors

.jpg)

Where can you find a Texas Christmas gift that promotes healthy smiles?

.jpg)

Powsmart Electric toothbrush Factory Arizona

.jpg)

How Does Powsmart App Connectivity Turn Real-Time Brushing Data into Actionable Insights?

The Working Principle of Sonic Electric Toothbrushes

.jpg)

Are Water Flossers with AI a Good Investment? An OEM Market Analysis