In modern high-performance water flossers, the integration of Hydro-dynamic Bearing systems with optimized Flow Channel Geometry is becoming a defining factor for achieving stronger pressure output, smoother water streams, and longer product lifespan. Manufacturers seeking to elevate their device performance increasingly rely on this pairing to reduce noise, enhance efficiency, and improve user experience in competitive global markets.

A Hydro-dynamic Bearing significantly improves motor stability by minimizing mechanical friction. Compared with traditional ball bearings, hydro-dynamic designs use fluid lubrication to support the rotary shaft, making the motor rotation more precise.

For water flossers, this stability ensures the flow pump delivers consistent pulsation frequencies—critical for producing high-pressure yet comfortable water streams.

High-performance water flossers often struggle with vibration and acoustic noise generated by the internal pump system. Hydro-dynamic Bearings solve this by creating a fluid film that dampens vibration at its source.

When combined with refined Flow Channel Geometry, the internal turbulence decreases, resulting in smoother water jets and quieter operation favored by premium consumer segments.

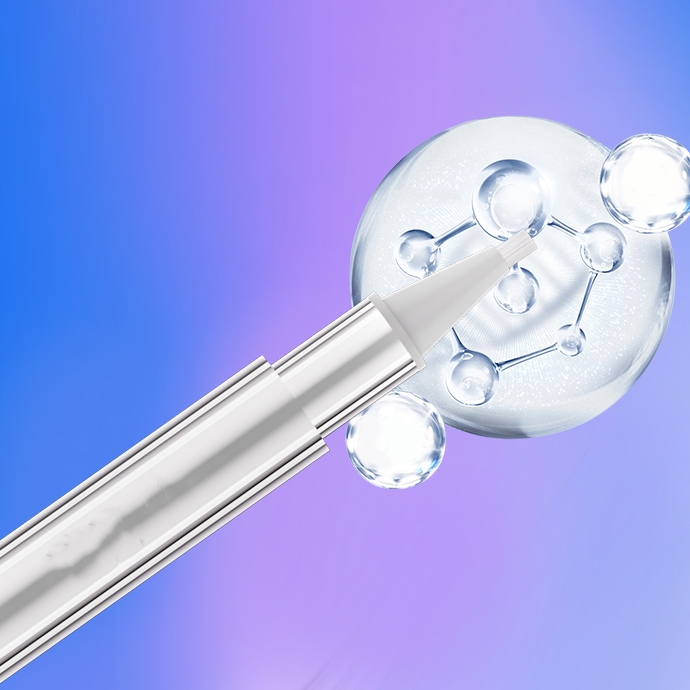

Flow Channel Geometry determines how efficiently water travels from the pump chamber to the nozzle. A well-designed channel reduces pressure drop, minimizes internal turbulence, and delivers stronger, more directed pulses to the user’s gumline.

Pairing this with Hydro-dynamic Bearing technology ensures the motor can maintain higher RPM performance, enabling consistent and powerful flow output.

For OEM/ODM manufacturers, the ability to deliver durable and reliable devices is essential. Hydro-dynamic Bearings have a longer operational life due to reduced mechanical wear.

When flow channels are also optimized, the system experiences less hydraulic resistance, meaning the motor does not need to work as hard. Reduced load equals prolonged lifecycles—translating to fewer returns and stronger B2B client confidence.

Modern water flosser brands seek slim, portable, and travel-friendly product formats. Hydro-dynamic Bearings allow for smaller motors without sacrificing performance thanks to better lubrication efficiency.

Meanwhile, refined Flow Channel Geometry ensures these more compact structures still achieve strong water pressure by maximizing internal flow efficiency.

Different global markets require unique performance profiles—high-pressure models, gum-sensitive variants, or children-friendly designs.

Hydro-dynamic Bearings provide the mechanical flexibility to fine-tune RPM stability, while Flow Channel Geometry can be digitally modeled to adjust pulsation, flow rate, and pressure output. This combination allows manufacturers to supply tailored solutions across various OEM/ODM product lines.

The synergy between Hydro-dynamic Bearings and advanced Flow Channel Geometry enables water flosser manufacturers to achieve exceptional performance, durability, and product differentiation. As consumer expectations continue rising, this engineering pairing will play an even more crucial role in shaping next-generation oral-care devices. Contact us

.jpg)

.jpg)

Choosing Electric Toothbrush Handle Processes: An OEM Guide to Cost vs. Quality

.jpg)

Waterproof IPX7 Toothbrush OEM | Durable Sonic Brush for Wet-Use Environments

Is a Quiet Electric Toothbrush Best for Seattle Apartments?

What Are the Common Points in the Production Process of Dental Irrigators and Electric Toothbrushes?

Why is Water Tank Molding critical for the stability of a Pressure Control System in flossers?

.jpg)

Bulk Smart Toothbrush Washington | Dental Giveaway & Corporate Programs

.jpg)

Electric Toothbrush for Orthodontists Wholesale | Professional Dental Supply

IPX7 Waterproof Electric Toothbrush Customization for Global Markets

Antibacterial Water Flosser Technology Trend: The Importance of UV Sterilization for Water Tank Hygiene Assurance

.jpg)

Gingival Recession from Cervical Hypersensitivity – Irreversible?

.jpg)

Ayurvedic neem toothbrush as an Indian household toothbrush

Why Is a Long Endurance Electric Toothbrush a Selling Point?

The Importance of Electric Toothbrushes in Oral Care

How Can Intuitive Touch Interface Design Incorporate a Reliable Child Lock Function?

App Connected Toothbrush: OEM Development for Smart Oral Care

.jpg)

Electric Toothbrush for Dental Kit Programs | Custom B2B Oral Care Solutions