In the competitive oral care market, every detail matters — from design aesthetics to the materials used in manufacturing. For brands seeking to collaborate with an OEM (Original Equipment Manufacturer), understanding how material choices influence quality, performance, and user satisfaction is key. The best toothbrush materials not only improve functionality but also enhance product value and long-term brand reputation.

When it comes to OEM quality, the materials used in toothbrush production form the foundation of reliability and performance. Premium bristle filaments like Dupont™ Tynex® or Pedex® offer superior flexibility, durability, and plaque-removing efficiency. Similarly, handles made from eco-friendly and BPA-free polymers or plant-based plastics elevate both sustainability and product safety standards.

By selecting high-grade materials, brands ensure their products meet international compliance standards — a key differentiator when marketing to health-conscious consumers.

A major factor that shapes the user experience is how the bristles interact with teeth and gums. The best toothbrush materials allow for innovations such as ultra-soft tapered bristles that reach between teeth and along the gumline more effectively. This not only enhances comfort but also reduces irritation, promoting daily brushing consistency and consumer loyalty.

Advanced bristle materials also maintain shape longer, preventing fraying and maintaining performance over time — a subtle but powerful way to enhance product value.

The handle is often overlooked, yet it plays a vital role in the brushing experience. Using high-quality elastomers or biodegradable materials ensures a comfortable grip while aligning with sustainability trends. OEM factories that offer a range of handle materials — from recycled PET to bamboo composites — give brands flexibility in both design and environmental messaging.

This strategic material choice enhances brand storytelling and reflects positively on the perceived OEM quality.

While premium materials might seem more expensive, they can actually reduce long-term costs. High-quality resins and precision molding reduce defect rates, improve consistency, and minimize rework. OEM partners with expertise in advanced materials can help brands strike the right balance between cost efficiency and enhanced product value.

Material selection also affects visual and tactile appeal — crucial for standing out on crowded retail shelves. Transparent resins, matte finishes, or color-stable polymers create an immediate sense of quality and innovation. OEMs with material engineering capabilities can help brands design toothbrushes that not only perform well but also look premium, reinforcing overall brand value.

Choosing an OEM partner experienced in material science ensures that your brand can leverage the best toothbrush materials effectively. Look for manufacturers who offer material testing, customization options, and compliance certifications. A knowledgeable OEM team can guide you in selecting materials that align with your target market’s needs — whether it’s sensitivity care, eco-conscious design, or luxury branding.

In today’s oral care industry, success depends on more than just design — it’s about how materials shape performance, sustainability, and the consumer’s everyday experience. By focusing on the best toothbrush materials, brands can significantly enhance product value, improve OEM quality, and deliver a superior user experience that builds lasting trust and loyalty. https://www.powsmart.com/about-powsmart/

How Could Electric Toothbrush Brands Stand Out Through Bristle Quality?

Building a Teeth Whitening Brand from 0 to 1: Differentiation Strategy Under the OEM Model

.jpg)

Private Label Teeth Whitening Kit Solutions for B2B Brands

.jpg)

How Does Desktop Irrigator Design Integrate an Anti-bacterial Hose for Long-term Hygiene?

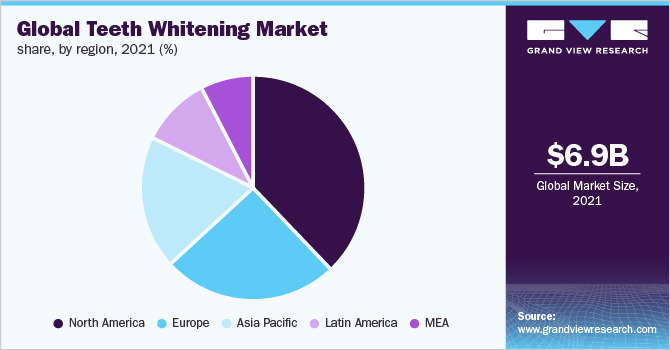

Analysis of Differences in Preferences for Teeth Whitening Devices in the European and American Markets vs. Asian Markets

.jpg)

Gentle Gum Care Electric Toothbrush Production for Sensitive Teeth

.jpg)

Tongue Numbness After Hydrogen Peroxide Burns – Normal?

Why Is a Dependable Toothbrush Battery Supplier Crucial for a Long-Lasting Toothbrush?

.jpg)

Seeking Electric Toothbrush for Hotels Supply or Electric Toothbrush for Dentists Supply?

.jpg)

Waterproof Failure Causing Material Toxicity? A Silent Risk in Oral Care Manufacturing

Why Include a Teeth Shade Guide with a Professional Salon Whitening Device?

What types of batteries are currently available for electric toothbrushes?

.jpg)

Pros and Cons: A Deep Dive into UVC and Ozone Sterilization Technologies

Fast Chargers & Electric Toothbrushes: A Manufacturer’s Technical Insight

The Market Prospect of LED Teeth Whitening Kit

Our electric toothbrush factory: manufacturing quality and Innovation