For OEMs and brands expanding beyond handles and heads, adding a Water Flosser to your oral-care portfolio is an obvious adjoint to the electric toothbrush. Properly engineered, a water flosser becomes a marketable Dental Plaque Remover for interdental and subgingival spaces while offering a comfortable, easy-to-use routine for consumers. Below are six product-level dimensions (design, performance, user comfort, hygiene, validation, and commercialization) that manufacturers should act on to build a credible, safe and sellable water-flossing product.

First and foremost, cleaning performance depends on three hydraulic parameters: peak pressure, pulse frequency, and average flow rate. To balance efficacy and comfort:

Next, nozzle geometry and jet coherence determine whether water reaches interdental spaces and sulci:

Moreover, comfort determines adherence. If flossing feels unpleasant or the device is noisy, usage drops quickly:

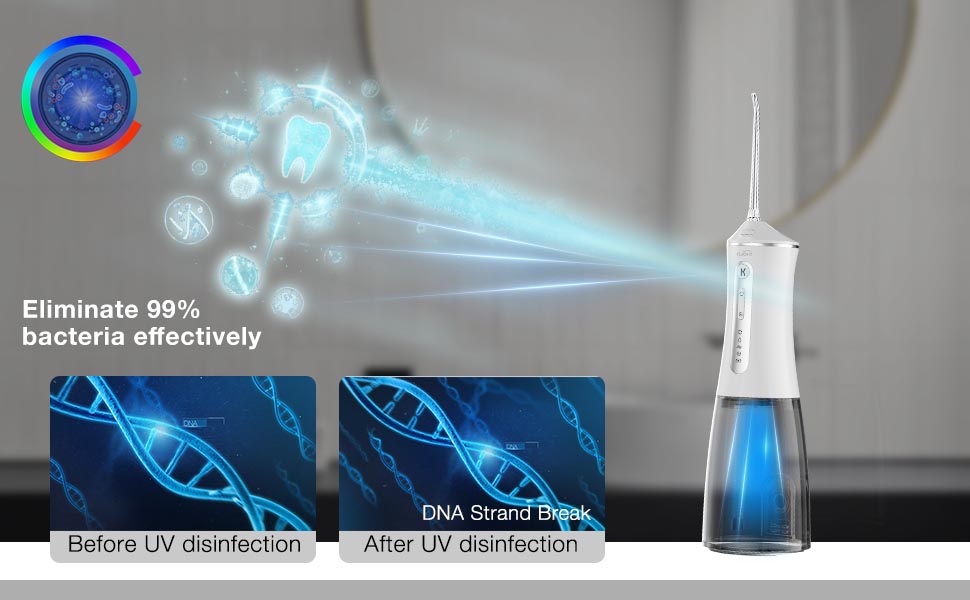

Additionally, hygiene engineering is mission-critical for interdental devices:

Crucially, don’t overpromise. Validate with a staged evidence plan:

Finally, water flossers sell best when they complement existing oral-care routines:

.jpg)

.jpg)

Battery Leakage, Shell Peeling Off… What Are the Familiar Problems with Unqualified Children Electric Toothbrushes?

Analysis of the Core Components of Electric Toothbrushes: How Do High-Performance Motors Improve Cleaning Efficiency?

Hidden Risks of Customizing Low-Cost Electric Toothbrushes & Water Flossers

Does Clinical Gum Mode Really Work?

Does Toothbrush Battery Life Impact Gum Recession Risk?

The Market Prospect of LED Teeth Whitening Kit

Why & How People Start a Teeth Whitening Business (Steps)

Can a Folding Toothbrush Design Make This Travel Electric Toothbrush Fit in a Wallet?

Technique Affecting Periodontal Pocket – How Deep Is the Impact?

.jpg)

Where to Source Charger Replacements in Tampa?

How to Achieve Green Production in a Water Flosser?

Electric Toothbrush Noise Reduction Technology: How to Achieve Silent Cleaning?

Seal Degradation Leading to Biofilm Regrowth – Preventable?

Innovations in Sweeping Vibration Toothbrushes

.jpg)

Can Chicago Black Friday deals cover Chicago toothbrush repair costs?

8 Unexpected Health Benefits of Good Oral Hygiene: Beyond the Basics

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Deep Clean

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Private Label Whitening Gel

electric toothbrush heads Ultra Soft

electric toothbrush heads Regular Clean

Electric toothbrush heads Charcoal Infused-Diamond

Customization Teeth Whitening Gel