In the competitive world of oral care device manufacturing, even minor design or production flaws can trigger unexpected user complaints. Recently, customer feedback has highlighted a curious pairing: taste alteration following tray misalignment in teeth whitening kits. While it may seem like a coincidence, this phenomenon deserves closer inspection from both a design and safety perspective. Could this be an early warning sign of deeper product faults?

Tray misalignment typically refers to a whitening tray failing to properly conform to the user’s dental arch. This issue can stem from:

A misaligned tray does not sit flush with the teeth, resulting in improper distribution of whitening gel across the enamel surface.

When a whitening tray fits poorly, taste alteration becomes a likely side effect for several reasons:

Such chemical exposure can result in a temporary or, in severe cases, prolonged disruption of taste function. Company web: https://www.powsmart.com/product/electric-toothbrush/

For end users, the combination of tray misalignment and taste alteration quickly translates into dissatisfaction:

For B2B manufacturers, these reactions mean increased returns, warranty claims, and potential damage to brand reputation, especially in premium market segments.

Several upstream factors contribute to this linked issue:

The lack of synergy between tray design and gel formulation magnifies the problem.

To avoid the risk of tray misalignment and its side-effect, taste alteration, manufacturers can:

These measures reduce the likelihood of poor tray performance and protect end-user sensory comfort.

Advanced innovations promise better outcomes in tray-based whitening:

B2B brands adopting these solutions will set new standards for both safety and user satisfaction.

The occurrence of taste alteration following tray misalignment is far from random—it signals deeper design and production weaknesses that demand attention. For manufacturers, addressing this issue isn’t simply about aesthetics or taste—it’s about trust, product reliability, and market competitiveness. By tackling this hidden link head-on, OEM and ODM suppliers can deliver whitening products that truly meet modern consumer expectations for both performance and comfort. Contact us

From a Chemical Perspective, Do Teeth Whitening Products Really Work?

.jpg)

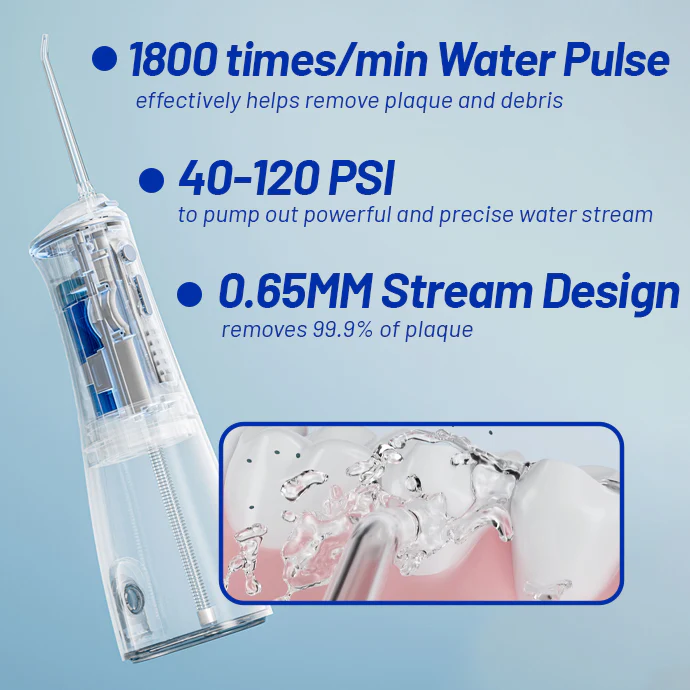

Benefits of Travel-Friendly Water Flosser Design

.jpg)

Is an Alaska portable charger necessary for an Alaska cold-resistant brush?

Pressure Sensor Failure with Taste Distortion – Related?

SF toothbrush deals vs. San Francisco sale — which is better?

How to Choose Good Bristle When Selecting an Electric Toothbrush

Appearance Economy Supply Chain: How to Improve Oral Care Product Appeal through Product Appearance Color

Cleaning Residue Plus Bristle Hardening – Double Trouble?

The Core Benefits of Brand Owners Promoting Water Flossers and How to Meet Marketing Needs to Increase Sales

How to Find an Electric Toothbrush Factory with Strong Comprehensive Capabilities

Why Electric Toothbrush & Water Flosser Bundles Sell Better

Custom Smart Toothbrush Manufacturing: From Design to Mass Production

Enamel Erosion with Cavity Acceleration – Vicious Cycle?

Tray Warping with Switch Corrosion – Time to Replace?

Cost Control and Quality Assurance Strategy of Electric Toothbrush OEM Production

How to Maintain Good Oral Hygiene Without Irritation?

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Deep Clean

Electric toothbrush heads Charcoal Infused-Diamond

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Ultra Soft

Customization Teeth Whitening Gel

Private Label Whitening Gel

electric toothbrush heads Regular Clean