In modern oral care manufacturing, performance and safety must evolve together. Selecting Food-grade Bristle Material from a trusted Micro Motor Supplier ensures that brush heads are engineered not only for effective cleaning, but also for material safety, mechanical compatibility, and long-term product reliability in high-frequency motor-driven systems.

Food-grade bristle materials are designed to meet strict safety standards for oral contact, while also withstanding the dynamic forces generated by micro motors. A qualified Micro Motor Supplier understands how bristle flexibility, resilience, and fatigue resistance interact with motor vibration and rotational speed.

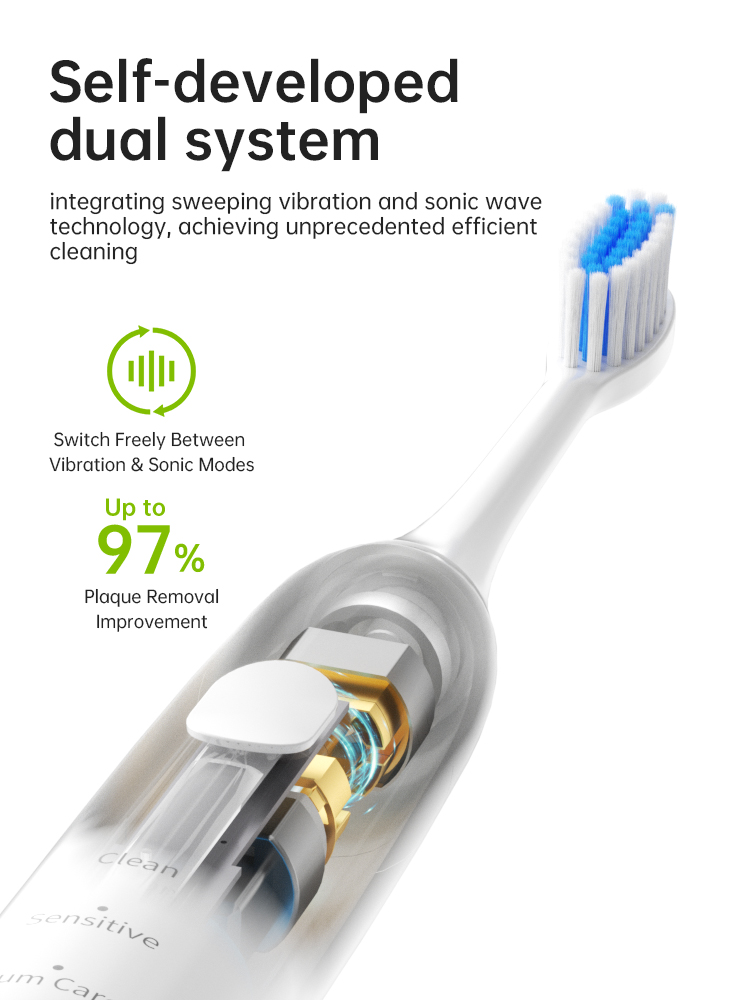

The efficiency of a brush head depends on how well bristles respond to motor-generated motion. When Food-grade Bristle Material is sourced through a Micro Motor Supplier, bristle stiffness and filament geometry can be matched precisely to motor torque and frequency for optimal plaque removal.

High-speed micro motors can accelerate bristle wear if materials poorly matched. Trusted suppliers select Food-grade Bristle Material with proven abrasion resistance and elastic recovery, helping maintain consistent brushing performance throughout the recommended replacement cycle.

A reliable Micro Motor Supplier typically works with standardized injection molding and tufting processes. This ensures that Food-grade Bristle Material integrates smoothly into automated production lines, reducing defects, variation, and downstream assembly issues.

Food-grade Bristle Material sourced through an experienced supplier supports compliance with FDA, EU, and other international safety frameworks. A knowledgeable Micro Motor Supplier helps align material documentation, testing protocols, and traceability requirements for multi-market distribution.

Beyond component sourcing, a trusted Micro Motor Supplier often provides system-level insights. This includes guidance on how Food-grade Bristle affects noise levels, vibration transmission, and overall user comfort in motor-driven oral care devices.

Choosing Food-grade Bristle from a trusted Micro Motor Supplier is a strategic decision that balances safety, performance, and manufacturability. By aligning material science with motor engineering, brands can deliver durable, compliant, and high-performing oral care products that stand out in competitive markets. Contact us

Teeth Whitener Regulations in EU & US: Strategic OEM Manufacturing Insights

7 Dentist-Approved Tips to Safely Whiten Your Teeth — and How They Can Help You Create Your Own Teeth Whitening Brand

.jpg)

dental care products importer USA

Mitigating LED Teeth Whitening Side Effects Through OEM Design & Formulation

How does a Water Pump OEM ensure compatibility with Precision Nozzle Manufacturing for water flossers?

Finding the Optimal Light Therapy for Teeth and Gums in OEM Products

.jpg)

electric toothbrush producer in the US

.jpg)

USA electric toothbrush maker

.jpg)

Electric Toothbrush Supplier California

How Does Packaging Customization Service Enhance the Appeal of Products with UV Sanitizing Component?

.jpg)

powsmart adult electric toothbrush

Teeth whitening kit manufacturers

.jpg)

Teeth Whitening Electric Toothbrush Manufacturer

.jpg)

Whitening Smart Pressure-Sensitive Sonic Electric Toothbrush

California Teeth Whitening Electric Toothbrush Manufacturers

.jpg)

B2B sonic toothbrush supplier for chain pharmacies California