Choosing the right electric toothbrush shell material is crucial for brand customers and manufacturers aiming to produce/sell high-quality, long-lasting, and environmentally responsible products. The durability, safety, and sustainability of the materials used directly impact consumer satisfaction and market competitiveness. In this blog, we will conduct a shell material comparison and provide a durability analysis to help you select the best option.

Electric toothbrush shells are typically made from various types of plastics and composites. The most commonly used materials include:

ABS (Acrylonitrile Butadiene Styrene)

PC (Polycarbonate)

PP (Polypropylene)

PLA (Polylactic Acid) – a biodegradable option

Each material has distinct characteristics that affect its durability and suitability for toothbrush manufacturing.

When evaluating the durability of electric toothbrush shell materials, factors such as impact resistance, wear and tear, and resistance to moisture must be considered.

ABS: Offers excellent impact resistance and toughness, making it a durable choice for long-term use.

PC: Known for its high strength and heat resistance, ensuring it withstands daily exposure to water and friction.

PP: Lightweight and resistant to chemicals, but may not be as tough as ABS or PC.

PLA: While an environmentally friendly material selection, its durability is lower than synthetic plastics, making it less suitable for long-term use.

The durability of an electric toothbrush shell is largely influenced by its ability to withstand accidental drops and prolonged use.

PC ranks highest in impact resistance, making it ideal for premium models.

ABS follows closely, providing a good balance of strength and cost-effectiveness.

PP is less resistant to physical stress, but its chemical resistance makes it a viable choice for specific applications.

PLA is biodegradable but not as robust, making it suitable for eco-friendly, short-term use products.

Manufacturers are increasingly considering environmentally friendly material selection in response to growing sustainability concerns.

PLA: The best biodegradable alternative, derived from renewable sources.

Recycled ABS/PC: Reduces plastic waste while maintaining durability.

Bio-based plastics: Emerging as a potential alternative, offering durability with reduced environmental impact.

The cost of materials impacts production scalability and profitability.

ABS and PP: Cost-effective and widely available.

PC: More expensive but justifiable for high-end products.

PLA and sustainable alternatives: Require investment but appeal to eco-conscious consumers.

When choosing the best electric toothbrush shell material, manufacturers must balance durability analysis, shell material comparison, and sustainability.

Durability: PC and ABS are the best choices.

Affordability: ABS and PP offer a budget-friendly option.

Sustainability: PLA and recycled materials are the preferred options.

By considering these factors, manufacturers can select the optimal material to enhance product performance and brand customers could select the reliable manufacturers to produce the high-quality products and meet consumer expectations.https://www.powsmart.com/about-powsmart/

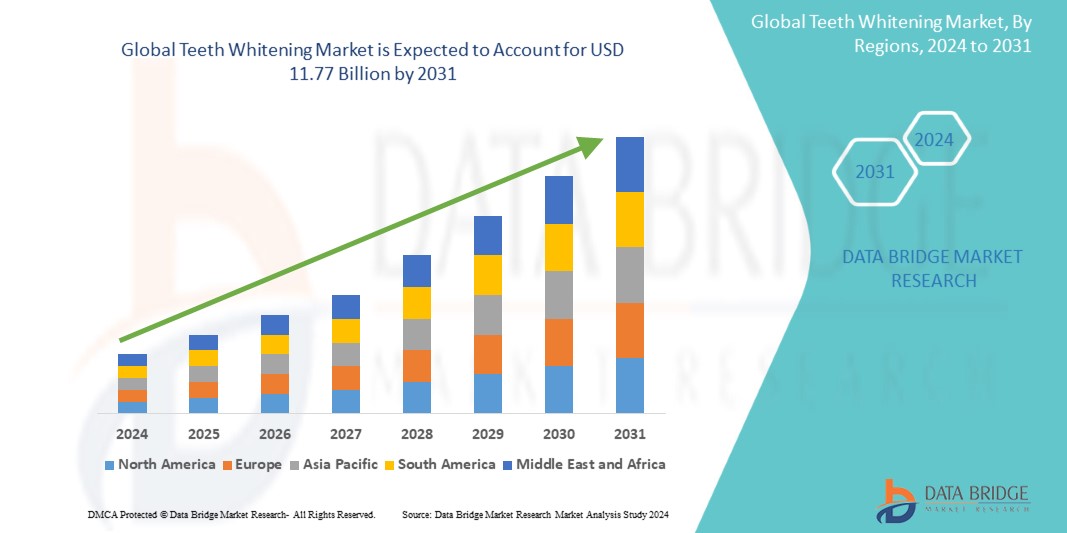

Global teeth whitening Device Market : Fastest Growing Regions and Consumer Group Portraits

How to Choose the Right Water Flosser Pressure Setting for Different Oral Types

.jpg)

water flosser OEM factory

How Wireless Tech is Revolutionizing Oral Care Devices

.jpg)

Pulse Instability with Noise Spikes – Motor Dying?

.jpg)

Why Do Whitening Cycles Cause Efficacy Debates?

Why is Quality Certification Support integral to a successful Contract Manufacturing agreement?

Electric Toothbrush Lifespan: When to Replace from an OEM Perspective

.jpg)

Material Degradation Releasing Chemical Residue? Hidden Hazards in Oral Care Devices

Can a High-torque Motor Achieve Low Power Consumption?

.jpg)

Cordless Compact Water Flosser OEM | Portable Oral Irrigator Manufacturer

Horizontal vs Vertical Brushing: How Smart Toothbrush Design Guides Proper Technique

Can an ISO13485 Electric Toothbrush Meet Quality Standards from a Waterproof Electric Toothbrush Factory?

.jpg)

LED Whitening Toothbrush OEM | Advanced Oral Care Manufacturing Solutions

.jpg)

Compact Whitening Device Wholesale for Global Distributors and Brands

Why Isn’t It Suggested to Design Patterns on the Brush Heads of Electric Toothbrushes?