As a professional manufacturer of electric toothbrushes, we understand that waterproof performance isn’t just a feature – it’s a fundamental requirement. Here’s why rigorous waterproof testing should be non-negotiable in your production standards.

Unlike sample testing, implementing 100% TEST waterproof verification ensures no defective unit reaches consumers. Our production line automatically subjects each toothbrush to full immersion testing, catching even the slightest seal imperfections that could lead to water damage. This commitment to comprehensive testing has reduced our warranty claims by 37% year-over-year.

IPX7 certification (30 minutes at 1 meter depth) represents the baseline for quality electric toothbrushes. We go beyond this standard with our proprietary 72-hour accelerated water resistance test that simulates years of bathroom conditions. Products that pass this extreme evaluation maintain perfect functionality even after prolonged real-world use.

True waterproofing begins before inspection at the design phase. Our engineering team uses:

Ultrasonic welding for seamless housing

Dual-layer silicone gaskets at all entry points

Nano-coating on internal circuits

This proactive approach ensures our products are born waterproof, not just tested to be so.

A single leak can destroy sensitive electronics, leading to:

42% higher return rates for non-waterproof models

3x more negative product reviews

Potential safety hazards from electrical shorts

Our stress testing data shows proper waterproofing extends product lifespan by at least 2 years.

Beyond standard IPX7 tests, our quality control includes:

500-cycle button press tests under water

Thermal shock cycling (-20°C to 60°C)

High-pressure spray testing at all angles

This multilayered verification gives buyers absolute confidence in our products.

Implementing 100% TEST waterproof verification:

Reduces liability risks

Enhances brand reputation

Creates marketing advantages

Our retail partners report 28% higher repurchase rates for toothbrushes with certified waterproof performance.

In today’s competitive market, IPX7 certification and 100% TEST verification should be standard requirements. Our experience proves that investing in comprehensive waterproof testing before inspection and throughout production delivers measurable returns through reduced returns, stronger brand equity, and longer customer relationships.

Manufacturer’s Insight: Consider offering waterproof performance guarantees as a premium differentiator. Our testing protocols can be customized to help you create compelling marketing claims backed by irrefutable data https://www.powsmart.com/

Efficient production line optimization and quality improvement for tooth flosser factory

Frequency and Tips for Using Your At-Home Mouthpiece Recommended by Your Dentist

.jpg)

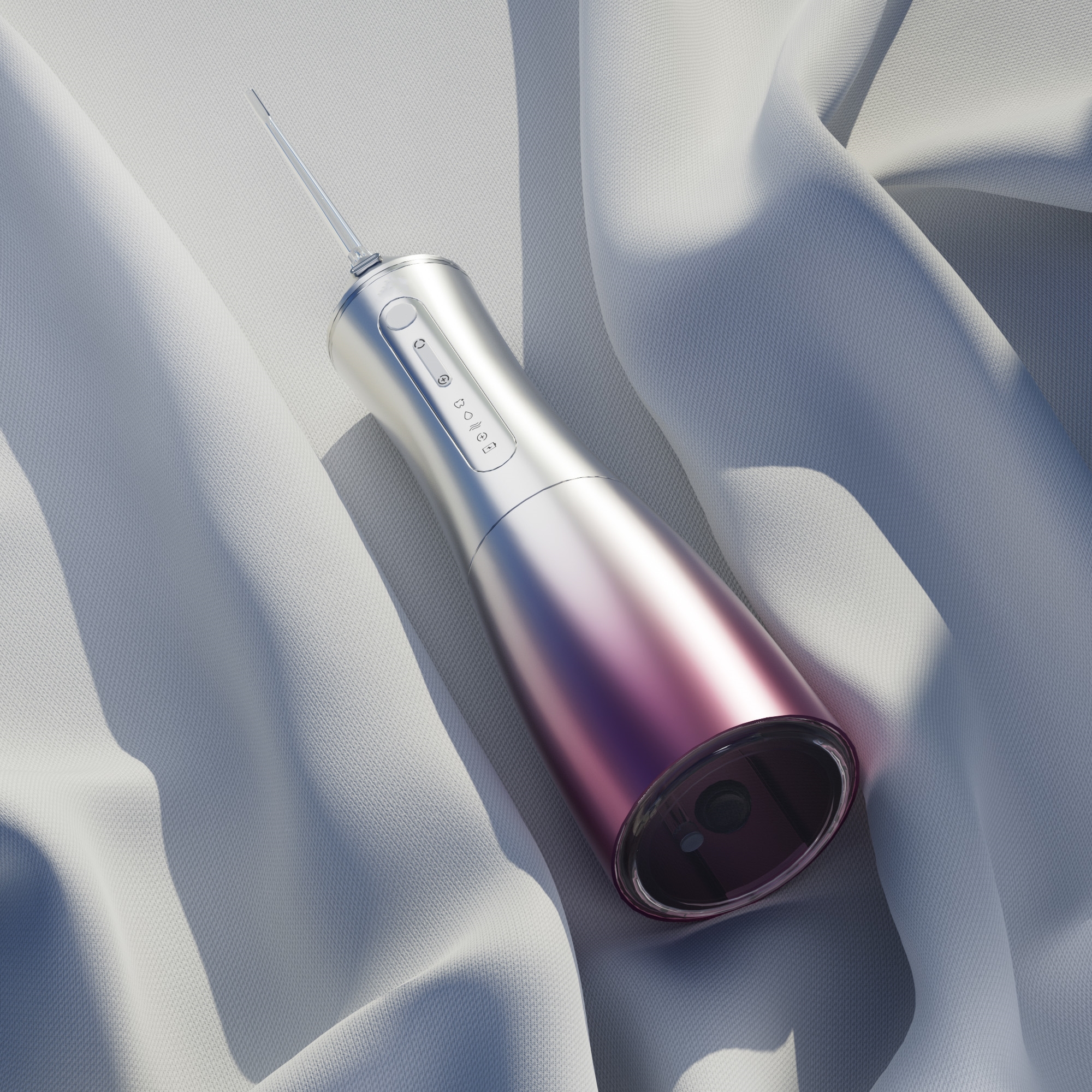

Need a Portable Water Flosser ODM that Incorporates Leak-proof Flosser Technology?

.jpg)

ADA Compliant Electric Toothbrush Supplier | Certified Oral Care Solutions

How does Pulse Water Technology benefit from the programmability of a Multi-pressure Chip?

San Francisco Electric Toothbrush Wholesale: Best Deals for Dental Clinics

What Makes a High-Quality Water Flosser? Material Choices for Durability and Performance

.jpg)

Father’s Day Gift Electric Toothbrush for Texas Dad

Tips from a water flosser factory: correct ways to use oral irrigator

Brooklyn Fast Local Delivery Electric Toothbrush Wholesale Suppliers

Dental Care Products Market – Is There Space for Startups?

.jpg)

Portable LED Whitening Mouthpiece Wholesale | Flexible LED Oral Tray Supplier

PowSmart’s Commitment to Quality: What Sets Our Oral Care Products Apart

.jpg)

Texas Distributor of Electric Toothbrushes

.jpg)

Electric Toothbrush with Long Battery Cycle Durability, Waterproof Design & Advanced PCB Technology

Do I Need FDA Approval to Sell Household Teeth Whitening Products?