In the fast-paced world of global supply chains, efficiency is key to staying competitive. However, data gaps in logistics and customs delays in international shipments are becoming major obstacles, disrupting timelines and increasing costs. Without accurate data and smooth customs clearance, manufacturers and suppliers face production setbacks, delayed deliveries, and dissatisfied customers. This article explores the causes of these challenges and provides actionable solutions to mitigate risks.

Accurate and timely data is the backbone of modern logistics. From order placement to final delivery, every step relies on seamless information flow. However, data gaps—missing, incomplete, or outdated information—can lead to:

Without a strong data management system, businesses struggle to anticipate delays and optimize inventory levels, causing inefficiencies across the supply chain.

As international trade regulations tighten, customs delays have become a common bottleneck. Factors contributing to these delays include:

These delays not only affect delivery schedules but can also result in financial penalties, damaged client relationships, and lost sales opportunities.

One of the biggest reasons behind customs delays is the presence of data gaps in shipment documentation. Missing or incorrect data can cause:

To avoid these risks, companies must implement robust digital documentation and tracking systems to ensure customs compliance from the start.

To combat data gaps, businesses should invest in digital solutions that enhance real-time data accuracy and shipment visibility. Effective strategies include:

By leveraging these technologies, companies can reduce manual errors, streamline customs clearance, and improve overall operational efficiency.

Beyond digital solutions, manufacturers and exporters must proactively address customs delays by:

By refining customs compliance strategies, companies can significantly reduce clearance times and maintain smoother supply chain operations.

To mitigate the impact of data gaps and customs delays in the long run, businesses should:

By proactively addressing these challenges, businesses can build a more resilient supply chain that withstands global trade disruptions.

The combined effects of data gaps and customs delays are causing significant supply chain inefficiencies. However, by embracing digital solutions, strengthening compliance measures, and adopting a proactive risk management approach, businesses can minimize disruptions and maintain timely deliveries. The key to success lies in ensuring data accuracy, leveraging technology, and maintaining a deep understanding of evolving international trade regulations.https://www.powsmart.com/product/electric-toothbrush/

Is the brush head replacement reminder function really useful?

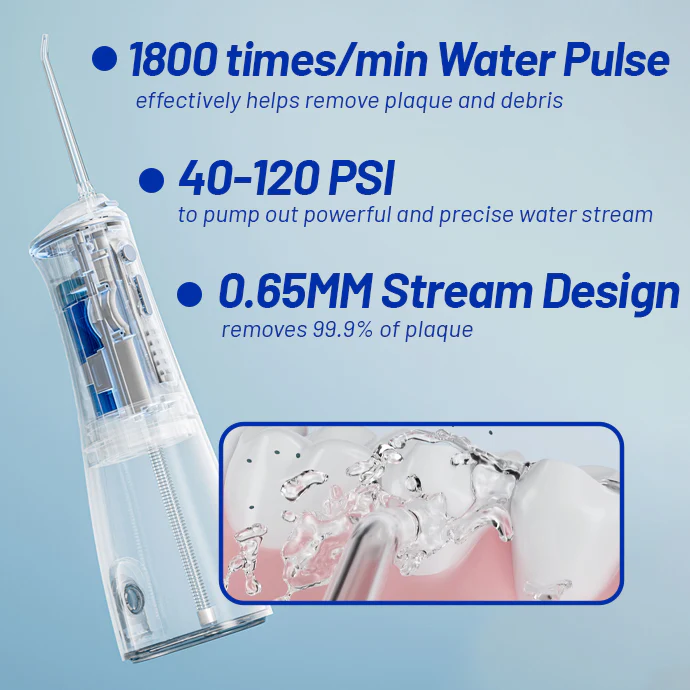

Private Label Water Flossers: Everything You Need to Know

.jpg)

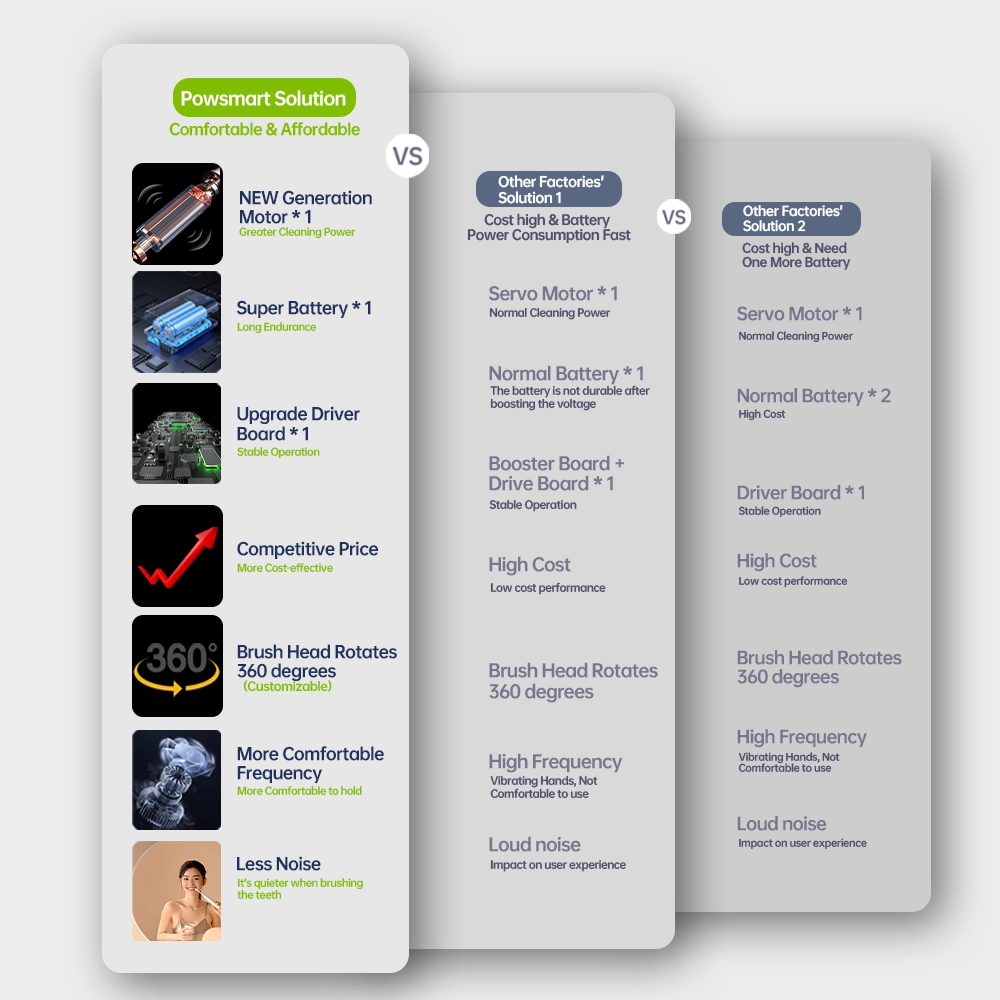

How an Oscillating-Rotating electric toothbrush removes plaque more efficiently

Market Access Made Simple: Understanding Regulations for Your OEM Whitening Kits

.jpg)

Is a whitening toothbrush the key to a Texas bright smile?

.jpg)

“Sterilization Function Electric Toothbrush: Efficient Cleaning & Health Protection”

.jpg)

Are Electric Toothbrushes Allowed in Carry-On Luggage? A Guide for Travel Brands

What is the process of customizing an exclusively designed electric toothbrush?

.jpg)

How to Choose a High-Profit Electric Toothbrush? A Must-Read Guide for Distributors

.jpg)

Sonic Toothbrush ODM Service for Global Oral Care Brands

.jpg)

Is Your Motor Vibration Failure Causing Brush Head Detachment?

The production of Electric Toothbrush Brush Heads

Are multiple cleaning modes worth it for a custom clean?

.jpg)

How Can R&D Collaboration Be Guided by Market Trend Analysis?

.jpg)

Small Batch Electric Toothbrush OEM for Flexible B2B Brands