Bringing a Custom Handle Design to market often requires balancing creativity, engineering feasibility, and production efficiency. Many brands wonder whether such customization can be executed smoothly within a Contract Manufacturing framework. The answer lies in selecting the right manufacturing partner—one with integrated R&D, tooling expertise, and scalable production capabilities to transform unique design concepts into commercially viable products.

A successful Custom Handle Design begins with collaborative development. Under a professional Contract Manufacturing agreement, engineering teams evaluate ergonomics, structural strength, waterproof requirements, and internal component layout at the design stage. This early feasibility assessment reduces redesign risks and shortens time-to-market.

Efficient realization depends heavily on tooling capability. Experienced Contract Manufacturing partners offer in-house mold development services, allowing rapid prototyping and structural validation. By optimizing mold flow analysis and material shrinkage compensation, manufacturers ensure that the Custom Handle Design can move quickly from concept to mass production without compromising precision.

Material choice directly affects durability, comfort, and compliance. Within a Contract Manufacturing structure, suppliers can recommend suitable ABS, PC, TPE overmolding, or medical-grade materials depending on product positioning. Proper material engineering guarantees that the Custom Handle Design meets both functional and regulatory requirements in global markets.

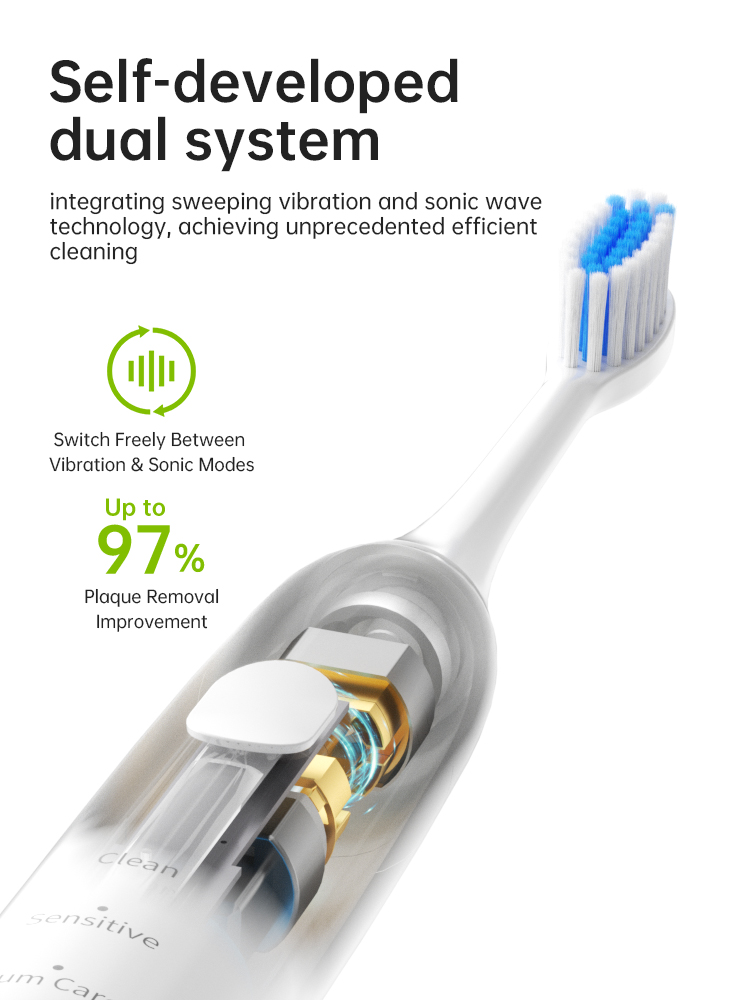

A handle is more than just an outer shell—it houses motors, PCBs, batteries, and sealing structures. Efficient Contract Manufacturing ensures seamless integration between industrial design and internal engineering architecture. This alignment prevents assembly complications and enhances product reliability, especially for waterproof or high-performance devices.

One of the advantages of Contract Manufacturing is production scalability. Once the Custom Handle Design is finalized, manufacturers can optimize production lines, automate assembly steps, and implement bulk material sourcing strategies. This structured approach maintains competitive pricing while preserving customization flexibility.

Customized designs must still meet international standards. Reliable Contract Manufacturing partners implement strict quality control protocols, including dimensional inspections, drop tests, waterproof testing, and certification documentation support. This ensures that the Custom Handle Design not only looks distinctive but also passes regulatory compliance in target markets.

Yes, a Custom Handle Design can be efficiently realized under a well-structured Contract Manufacturing agreement—provided the manufacturing partner offers integrated design support, tooling expertise, material optimization, and scalable production management. Contact us

1-1024x683.jpg)

.jpg)

What Should Be Noted When Developing or Selecting Children’s Oral Care Products?

Tips to Select the Best Teeth Whitening Refill Kits Factories

.jpg)

Sonic Toothbrush Dallas – Smarter Cleaning Technology

.jpg)

Low-Noise Sonic Toothbrush Wholesale – Quiet Performance for Global Markets

Overcoming Supply Chain Challenges in Oral Care OEM Manufacturing

OEM Electric Toothbrush Quality Manufacturing in USA Texas

.jpg)

Why Do Pediatric Warnings Address Bleach Residuals?

.jpg)

Why Is Allergen Testing Critical for Post-Whitening Diets?

Conducting Bulk Material Sourcing?

.jpg)

Why Use Chromophore Targeting Gel With a Dental Water Jet for Enhanced Stain Removal?

What Are the Benefits of a Lithium Battery Pack in a Home Use Whitening System?

.jpg)

replaceable brush head toothbrush supplier | OEM & Private Label Factory in China

Horizontal vs Vertical Brushing: How Smart Toothbrush Design Guides Proper Technique

Can APP Connectivity Development Enhance Brushing Data Tracking for Users?

.jpg)

Hotel Amenity Electric Toothbrush Supplier

.jpg)

Hose Leakage Leading Mucosal Lesions – Double Damage?