As consumer awareness of hygiene grows, water flossers with sterilization capabilities—especially those using ultraviolet sterilization water flosser—are rapidly gaining popularity. The core question manufacturers and brands must answer is: how can we guarantee a 99% sterilization rate without compromising user safety or device performance?

This blog explores the working principles behind UVC disinfection technology, evaluates methods for sterilization rate testing, and discusses how manufacturers can deliver OEM customized solutions that meet market demand.

Ultraviolet sterilization teeth systems rely primarily on UVC light, a short-wavelength ultraviolet light (between 200–280 nm) that can penetrate microbial cells and destroy their DNA, effectively killing bacteria, viruses, and fungi.

In water flossers, UVC modules are typically embedded in:

This integration ensures continuous or on-demand sterilization of internal components, greatly improving hygiene during daily use.

UVC disinfection technology is the backbone of modern sterilizing water flossers. Key features include:

Advanced models utilize smart sensors to regulate sterilization time and intensity, further optimizing safety and effectiveness.

To ensure reliability, manufacturers conduct thorough sterilization rate tests using standardized microbiological methods. These tests usually involve:

Only devices that consistently show over 99% reduction in microbial count pass the benchmark. These validated results not only ensure product safety but also serve as marketing advantages when communicating performance to consumers.

For brands looking to enter or expand in the high-end oral care market, manufacturers offer OEM customized solutions tailored to their specifications. This includes:

With professional R&D and tooling teams, manufacturers can support both large-scale OEM orders and low-MOQ boutique brands seeking differentiation through hygienic innovation.

The integration of ultraviolet sterilization water flosser technology in water flossers is no longer a luxury—it’s becoming a standard. By combining effective UVC disinfection technology, verified sterilization rate tests, and scalable OEM customized solutions, manufacturers can offer next-generation products that meet both hygiene expectations and market trends.

Looking to develop your own line of smart, sterilizing water flossers?

? Contact us today to learn how our expert teams can bring your product vision to life—efficiently, affordably, and with guaranteed performance.https://www.powsmart.com/contact-us/

The Future of Toothbrush Sterilization: OEM Integration of UV and Antibacterial Tech

A Guide to the Pros and Cons of Two-in-One Electric Toothbrushes and Oral Irrigators

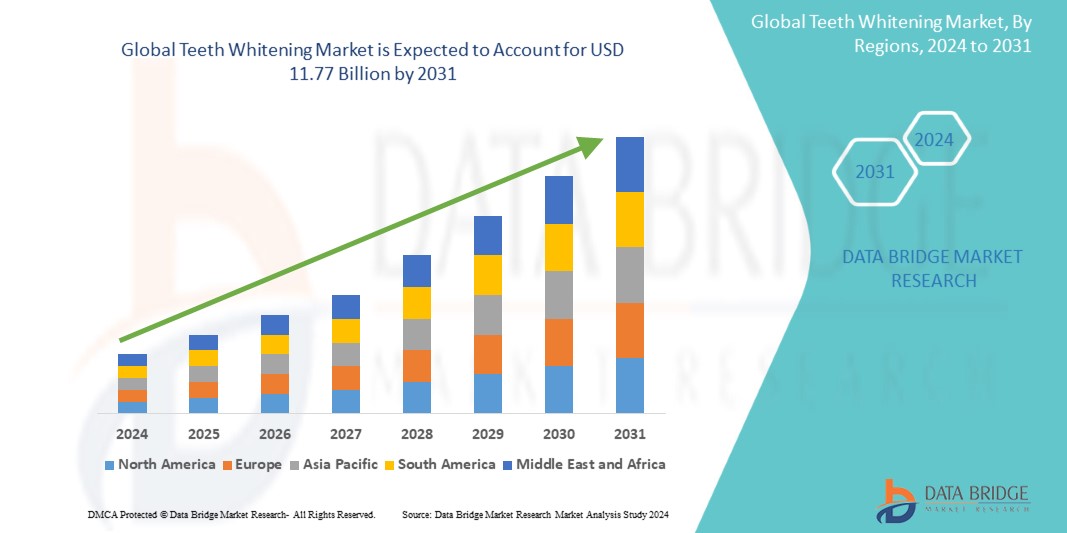

Global teeth whitening Device Market : Fastest Growing Regions and Consumer Group Portraits

.jpg)

No More Missed Spots: How Our Manufacturer Ensures Your Water Flosser Reaches All Teeth

-1.jpg)

Children’s Electric Toothbrush OEM – Safe and Fun Texas Manufacturing

.jpg)

Pressure Sensor Toothbrushes: Prevent Over-Brushing with Smart Tech

.jpg)

Enamel Scratching from Gum Irritation – Reversible?

How to Avoid Infringement Issues When Developing a Private Brand Electric Toothbrush

Advantages of a Travel-Size Toothbrush You Should Know

Does Black Electric Toothbrush ODM Face Handle Corrosion?

.jpg)

Electric Toothbrush Packaging Compliance for Global Markets

.jpg)

Dentist Recommended Electric Toothbrush | Washington State Guide

Solutions for Electric Toothbrushes noisy problem

.jpg)

OEM Smart Toothbrush Manufacturer | Custom B2B Solutions for Global Brands

.jpg)

Motor Burnout Causing Nozzle Clogging?

.jpg)

High-Frequency Toothbrush Wholesale for Global B2B Distribution