In the manufacturing of personal oral care devices, charging failure and tank odor may appear to be unrelated issues. However, recent field reports and internal quality audits reveal a surprising correlation—especially in water flossers and multifunctional electric devices. These two symptoms often occur simultaneously, signaling a deeper systemic flaw in device design or material interaction.

One of the primary causes linking charging failure and tank odor is moisture ingress. When the sealing integrity between the tank and the electrical housing is compromised—even slightly—water vapor can penetrate into the internal circuitry. This results in:

In many cases, a user may notice an unpleasant smell from the tank just days before the device fails to recharge—a subtle but telling warning.

Another contributing factor lies in subpar material selection. Low-grade plastics used in the tank or inner components can leach chemicals when exposed to repeated moisture and temperature fluctuations. These materials:

Thus, a single mistake in resin sourcing or molding standards can trigger both hygiene and hardware issues. Company web:https://www.powsmart.com/product/electric-toothbrush/

In well-engineered devices, fluid-containing parts and charging components are hermetically separated. However, in cost-sensitive models, design shortcuts can lead to:

These oversights significantly increase the chance of charging failure and persistent tank odor developing together over time.

Beyond engineering, user habits play a critical role. When consumers:

…the likelihood of joint failures rises. Many users report noticing charging errors immediately after a prolonged period of storage with water left inside the tank—conditions perfect for microbial growth and internal damage.

To avoid these issues and protect brand reputation, OEM manufacturers should:

Routine audits during production and post-assembly simulation testing under high humidity conditions can expose vulnerabilities early.

For private-label and ODM brands, proactively solving the link between charging failure and tank odor becomes a competitive edge. Consider:

The coincidence of charging failure and tank odor is not random—it signals a failure in moisture management, material strategy, or compartmental design. For manufacturers, it’s an opportunity to re-evaluate product architecture and align quality standards with consumer expectations.

Let us help you engineer smarter water flosser systems that stay fresh—and fully functional. Conatact us

.jpg)

Navigating Electric Toothbrush Import Regulations?

.jpg)

Electric Toothbrush for Subscription Brands

.jpg)

How Do Bristle Deformation and Nozzle Clogging Affect Oral Cleaning?

How Does a Teeth Whitening LED Kit Fit into the At-Home Beauty Device Market?

.jpg)

Water Flosser for Braces Supplier for Orthodontic Care Markets

.jpg)

Peroxide Free Whitening Device Supplier for Global Oral Care Brands

Do You Need a License to Sell Oral Beauty Products in Australia?

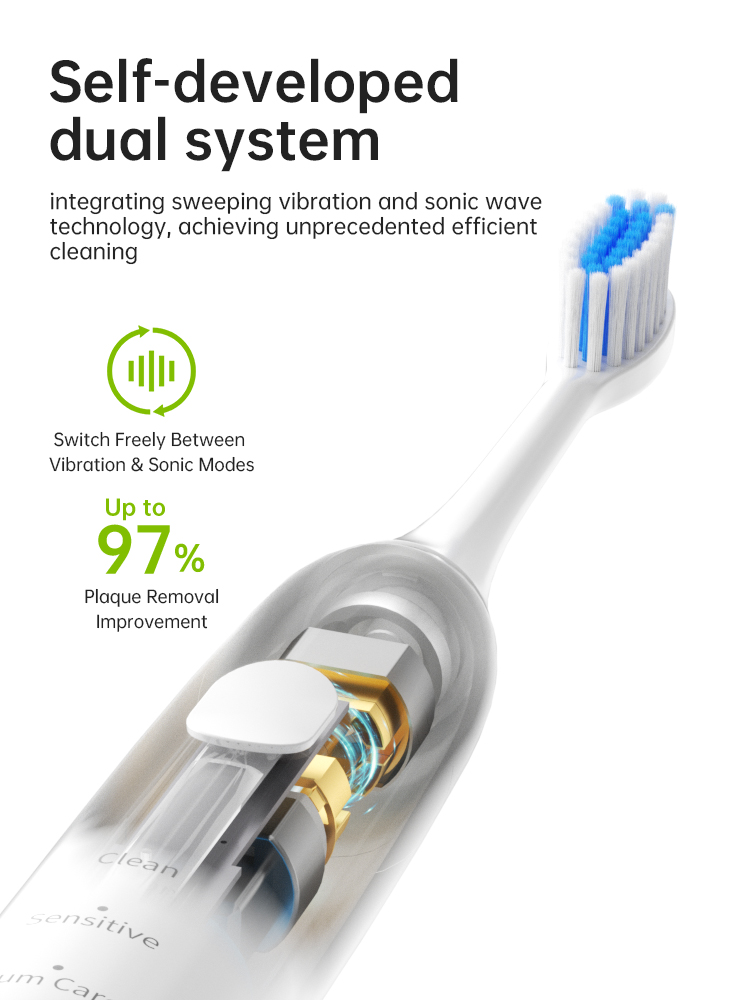

Innovative Features That Make Your Electric Toothbrush Stand Out

.jpg)

Electric Toothbrush Manufacturing Process Explained for B2B Buyers

Does Deep Clean Toothbrush Mode Cause Timer Malfunction?

Building Quality Water Flossers: Essential Standards for Home Use & OEM Production

-2-scaled.png)

How to Source the Best Teeth Whitening Device Manufacturers for Your Brand

Creating the Most Effective Electric Toothbrush: Key OEM Technologies Explained

.jpg)

Unlocking Convenience: Why Cordless Design Makes Water Flossers Perfect for Travel

Planning a Toothbrush Subscription Box for Your Direct-to-Consumer Brand?

.jpg)

Luxury Electric Toothbrush Manufacturer