When electrical integrity meets biological vulnerability, even minor design flaws can escalate into serious health risks. In the case of charging corrosion and mucosal lesions, manufacturers face a dual-threat scenario: one technical, one medical. Could electrochemical wear at the charging port be linked to soft tissue injury? And more importantly, is this interaction potentially fatal? In this article, we explore the hidden link between material degradation and biological exposure—highlighting key considerations for OEM and ODM developers.

Charging corrosion refers to the gradual degradation of metal contact points, typically caused by moisture ingress, saliva exposure, or repeated plugging in humid environments. This corrosion is more than just an aesthetic issue; it can lead to:

In devices like electric toothbrushes or oral irrigators, the charging port is often located close to the user’s mouth or skin—making any breakdown potentially hazardous.

Mucosal lesions are ulcerative or inflamed patches on the inner cheeks, lips, or gum tissues. While these may arise from mechanical abrasion, they can also result from:

When a device suffers from charging corrosion, small fragments of oxidized material may detach and contaminate mouth-adjacent surfaces. In worst-case scenarios, these can lodge in mucosal tissue and cause localized inflammation or even allergic reactions.

Here’s how the process unfolds:

This seemingly indirect route of injury makes charging corrosion a silent contributor to mucosal lesions, often going unnoticed until symptoms worsen. Company web: https://www.powsmart.com/product/electric-toothbrush/

Several design and material factors heighten the risk of this fatal pairing:

Such weaknesses are especially critical in B2B shipment to tropical or coastal markets, where moisture and salt accelerate corrosion cycles.

To mitigate these risks, responsible OEM/ODM manufacturers should:

These steps not only prevent technical failure but also protect users from potential mucosal lesions due to ion or debris exposure.

From a business standpoint, ignoring corrosion-to-tissue hazards opens doors to:

For B2B clients, it is essential to ensure that manufacturing partners:

By proactively addressing the charging corrosion and mucosal lesion link, you position your product—and your brand—at the forefront of safety-first innovation.

Is the pairing of charging corrosion and mucosal lesions fatal? Not always—but it’s certainly critical. For any device that resides near the oral cavity or facial skin, manufacturers must treat this issue with the seriousness it deserves. The fix is not only possible, but also necessary for maintaining trust, safety, and long-term value in today’s competitive market. Contact Kiwibird

-300x300.jpg)

-300x300.jpg)

.jpg)

low noise sonic toothbrush supplier | Quiet Sonic Toothbrush OEM Manufacturer

.jpg)

Electric Toothbrush Parts & Accessories Supplier

.jpg)

Travel Size Electric Toothbrush Wholesale

How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?How Does Pulse Water Technology Benefit from a Smart Multi-pressure Setting Chip?

.jpg)

Why Should a Portable Travel Toothbrush Supplier Partner with a Toothbrush Subscription Box Partner?

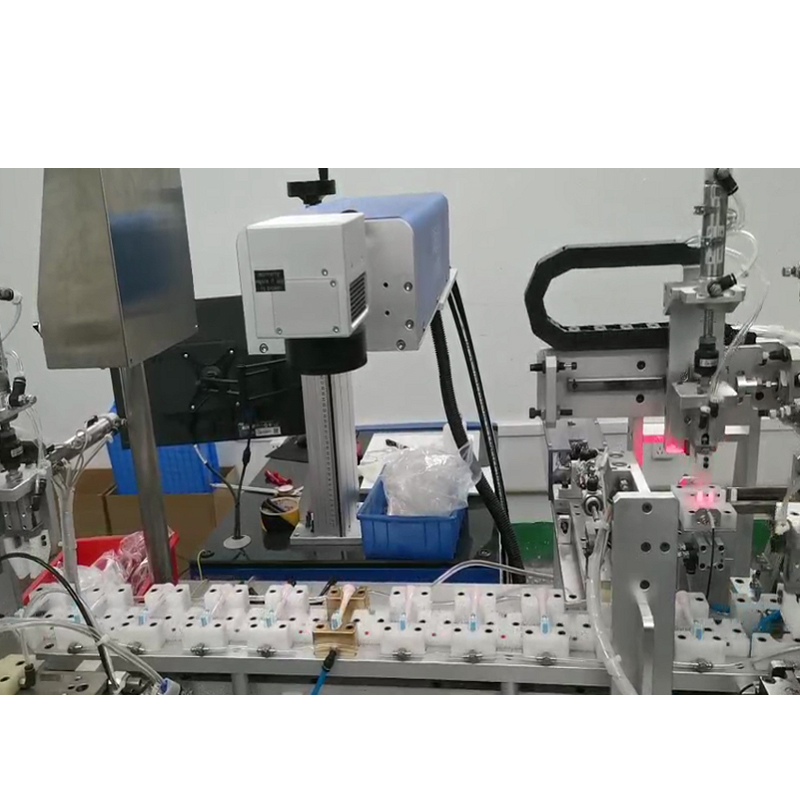

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?

.jpg)

Frequent Allergy Reactions to Whitening Kits: Is Cold-Light Technology to Blame?

Smart Home Health Devices: Connected Toothbrush OEM Solutions

Sourcing Kids Electric Toothbrush Hyderabad: Regional OEM Manufacturing

.jpg)

Split Bristles Linked to Enamel Cracks? 90% of Users Ignore This Danger!

.jpg)

low noise electric toothbrush OEM factory | Quiet Sonic Manufacturer

.jpg)

Does Warranty Cover Motor Overheating in Electric Toothbrushes?

.jpg)

Does Teeth Whitener Cold Light Radiation Accelerate Enamel Demineralization? Lab Results Revealed!

.jpg)

ergonomic sonic toothbrush wholesale | Comfortable Grip Design OEM Factory

AI Powered Toothbrush: Next-Generation OEM Technology

.jpg)

premium metal body electric toothbrush OEM | Luxury Design Manufacturer