In the increasingly competitive smart oral care market, reliability and consistency are expected as the baseline. However, users and industry auditors alike are raising concerns about simultaneous mode confusion and timer malfunction in some electric toothbrush models. These issues not only disrupt user experience but can severely impact brand trust and compliance in clinical and export markets.

Most high-end electric toothbrushes offer multiple brushing modes—whitening, sensitive, gum care, etc.—alongside built-in timers to guide users toward optimal brushing time. Yet, when brushing modes switch erratically or timers fail to signal accurately, the entire brushing session becomes ineffective or even uncomfortable.

This dual malfunction often goes unnoticed in early QC but becomes highly visible during consumer use, leading to frequent complaints and high return rates.

Mode confusion refers to inconsistent behavior in brushing patterns: skipping modes, randomly switching intensity levels, or failing to respond to user input. The common technical triggers include:

These malfunctions not only disrupt the user’s habit but can result in over-brushing or underperformance, especially in sensitive oral conditions.Company web: https://www.powsmart.com/product/electric-toothbrush/

It is not a coincidence that timer malfunctions often accompany mode instability. In many designs, brushing mode logic and timer circuits share the same MCU or clock signal. If either becomes unstable, both systems fail. Typical signs include:

For OEMs and brands, these signs should not be dismissed as minor errors—they can signal deeper control system deficiencies.

While a skipped timer or mode shift may seem trivial, users may experience:

In regulatory terms, a failure to deliver consistent timing or brushing force could also put some smart brushes in violation of performance claims.

To avoid mode and timer issues, experienced manufacturers must adopt:

Such measures significantly improve functional integrity and reduce costly recalls.

B2B buyers sourcing electric toothbrushes must dig deeper during factory selection. Key questions include:

Only by choosing an OEM with robust electronic integration and firmware sophistication can brands avoid the pitfalls of mode confusion and timer malfunction in mass production.

As electric toothbrushes evolve into smart health tools, overlooking synchronization between brushing modes and timers can result in serious functional setbacks. Mode confusion paired with timer malfunction is more than an inconvenience—it signals design immaturity and quality oversight. Manufacturers committed to smart, reliable design must address both at the system level. Our factory specializes in precision circuit integration and long-cycle reliability testing to ensure stable user experiences.

.jpg)

How Does a Toothbrush Packaging Supplier Enable Custom Logo Packaging for Brand Identity?

.jpg)

Motorized Toothbrush Testing & Overall Solutions | Quality Assurance

.jpg)

Can Improper Frequency Settings Affect Cleaning Efficiency and Gum Health?

.jpg)

Austin Eco Toothbrush: Sustainable Oral Care from Factory to Home

.jpg)

Pressure Sensor Failure with Taste Distortion – Related?

Essential Considerations for Electric Toothbrush OEM Projects

Home Teeth Whitening Device – A Must-Have Before a Date

1-scaled.jpg)

The Growing Demand for At-Home Teeth Whitening & What It Means for Brands

.jpg)

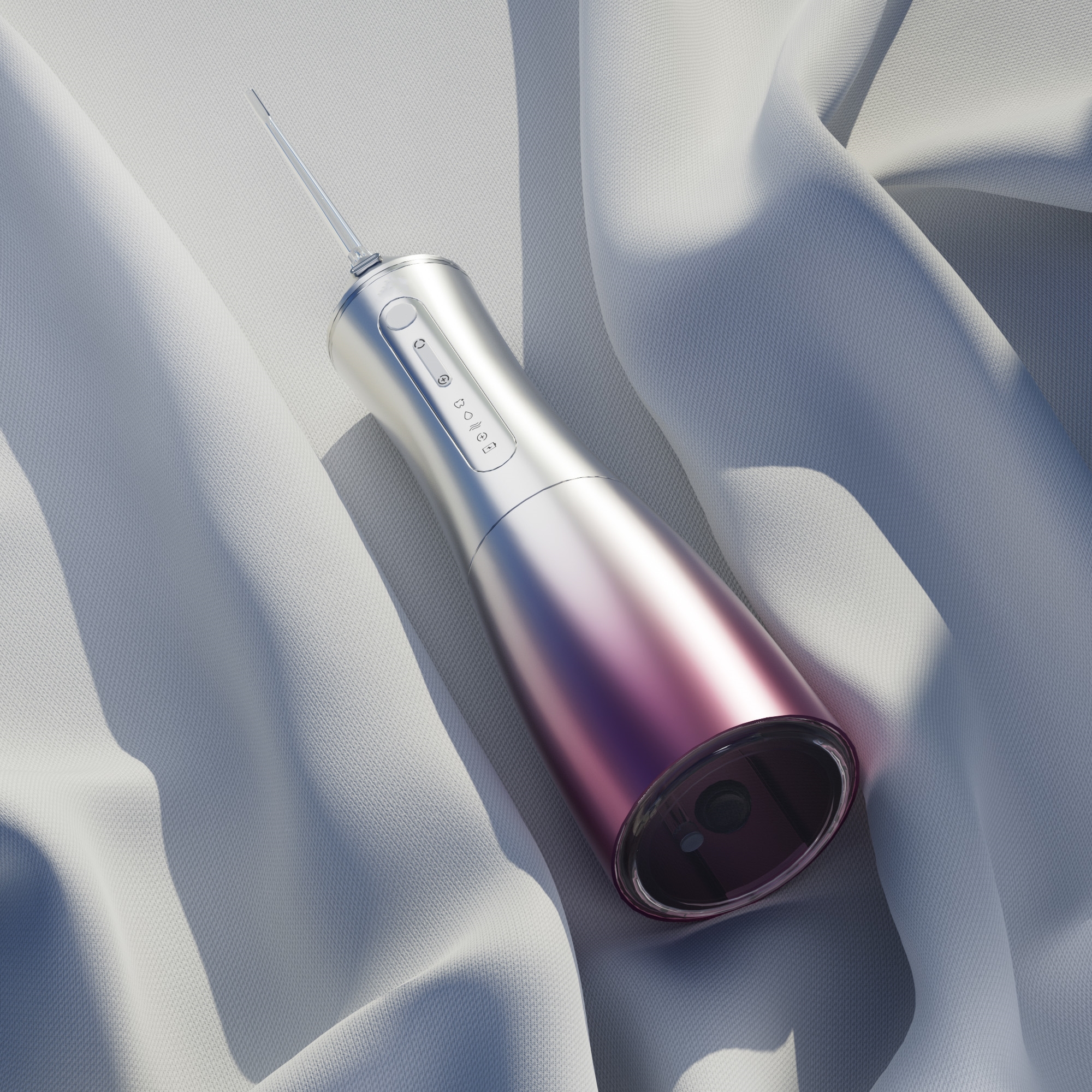

Perfect Pressure Every Time: Designing User-Friendly Water Flosser Settings for Your OEM Brand

Identifying Chinese Electric Toothbrush Manufacturers That Listen and Improve With Your Feedback

Holiday Gift Sets for Clients – Custom Oral Care Corporate Gifts

Can a Torque Control Motor Benefit from Advanced Kinematic Pair Design in Electric Toothbrushes?

.jpg)

Smart Toothbrush Private Label: Build Your Brand with OEM Support

.jpg)

Downtown Chicago Electric Toothbrush Repair Services

Cracked a crown? Tacoma repair services for dental crowns — fast?

How Can Smart App Connectivity Boost User Engagement Through Bluetooth App Integration?