In smart oral-care devices like electric toothbrushes, app connectivity loss and battery swelling often appear together—eroding user trust and posing safety risks. To solve both issues, B2B manufacturers must address four major domains: waterproof sealing, thermal management, firmware logic, and structural design. Below are six key insights and action steps.

First, aging waterproof seals allow moisture to penetrate:

Once water seeps in, it both swells the battery pouch and corrodes Bluetooth modules—triggering battery swelling and app connectivity loss simultaneously.

Next, a swelling battery worsens heat dissipation issues:

Improving heat management is therefore essential to stabilize both the battery and wireless link.

Moreover, firmware safety routines can inadvertently cut off connectivity:

Harmonizing battery management and Bluetooth control logic prevents “false positive” shutdowns.Company web: https://www.powsmart.com/product/electric-toothbrush/

Meanwhile, swelling exerts mechanical stress on internal components:

Designing in expansion tolerance, using flexible PCB traces, and reinforcing adhesive bonds can mitigate these failures.

To catch issues before shipment, implement these tests:

Embedding these protocols into your QMS ensures out-of-box reliability.

Finally, control risks at the source with:

Ongoing supply-chain vetting and agile R&D form the long-term solution to co-occurring battery swelling and app connectivity loss.

Conclusion

When app connectivity loss and battery swelling arise together, it signals systemic gaps—in sealing, thermal design, firmware coordination, and structural robustness. By addressing these six dimensions, B2B manufacturers can build truly dependable smart oral-care devices. Contact us to tackle your communication and safety challenges head-on!

.jpg)

Need an OEM Electric Toothbrush with Comprehensive Custom Branding Service?

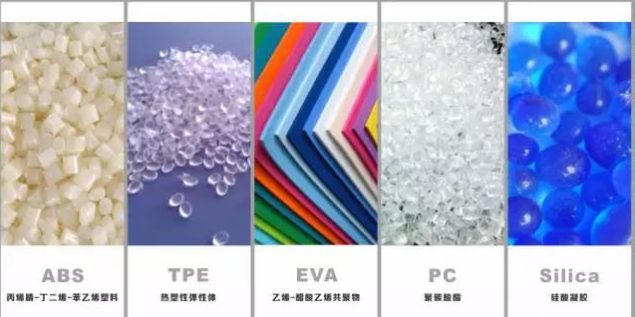

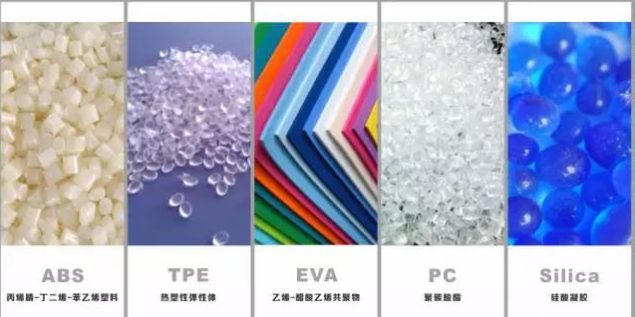

Oral Care Products CPSR Material List: Ensuring Safety and Compliance

.jpg)

Brush Head Blockage Causing Motor Stalling?

Does Children’s Cavity Prevention Brush Have App Connectivity Flaws?

What Are Electric Toothbrushes Made of?

Creating the Most Effective Electric Toothbrush: Key OEM Technologies Explained

Is a Business owner toothbrush worth a Surat premium gift investment?

What’s the Most Effective Way to Whiten Teeth at Home? An OEM Factory’s Insight

Marketing Support from OEM Partners: Beyond Manufacturing

.jpg)

Are Pressure Sensor Errors Worsening Hygiene Mode Absence?

.jpg)

Long Battery Life Electric Toothbrush OEM Supplier

.jpg)

Electric Toothbrush with Replaceable Battery

Do Black Friday Deals Boost Electric Toothbrush Sales in Chicago?

.jpg)

Procuring Electric Toothbrush for Hotels Supply?

Wavelength of Whitening Teeth Device Blue Light (460–490nm) and Red Light (620–660nm)Configuration Guide

Start New Year Product Sourcing with Oral Care Products OEM