When developing advanced personal care or medical devices, integrating a Wireless Charging Coil with a high-performance drive system requires seamless engineering coordination. That’s why partnering with a supplier who is not only an expert in wireless power solutions but also a trusted Micro Motor Supplier can significantly enhance product performance, reliability, and production efficiency. A unified supply partner minimizes integration risks while maximizing innovation potential.

A Wireless Charging Coil operates within strict electromagnetic and thermal parameters, while micro motors demand stable voltage and current control. When your Micro Motor Supplier also designs or supplies the charging coil, both systems can be optimized together.

This integrated engineering approach ensures:

Such coordination avoids compatibility issues that often arise when sourcing components from separate vendors.

Modern devices demand compact, lightweight designs. The layout of a Wireless Charging Coil directly affects internal space allocation for the motor, PCB, and battery.

A supplier experienced in both coil and motor systems can:

This synergy leads to sleeker product designs without compromising performance.

A high-quality Wireless Charging Coil must deliver consistent energy transfer, while a precision micro motor requires controlled power input for optimal torque and speed.

When one Micro Motor Supplier manages both components, they can:

The result is longer operating time and better energy performance for end users.

Testing electrical and mechanical components separately may overlook system-level performance risks. A unified supplier can conduct integrated testing, including:

By evaluating the Wireless Charging Coil and motor as a combined system, the Micro Motor Supplier ensures consistent product reliability across large-scale production.

Working with multiple vendors often slows communication and complicates troubleshooting. A supplier that handles both Wireless Charging Coil production and motor manufacturing simplifies coordination.

Benefits include:

This integrated approach accelerates time-to-market—an essential advantage in competitive B2B environments.

Consolidating sourcing with a single Micro Motor Supplier reduces procurement complexity and logistics costs. Bulk material purchasing, synchronized production planning, and centralized quality management all contribute to cost optimization.

Additionally, supply chain risks are minimized because both the Wireless Charging Coil and motor components are managed under one coordinated production strategy.

Choosing a supplier that delivers both a high-performance Wireless Charging Coil and serves as your trusted Micro Motor Supplier is more than a convenience—it is a strategic advantage.

From integrated engineering and optimized power efficiency to streamlined quality control and supply chain stability, this unified partnership model strengthens product competitiveness while simplifying manufacturing management. Contact us

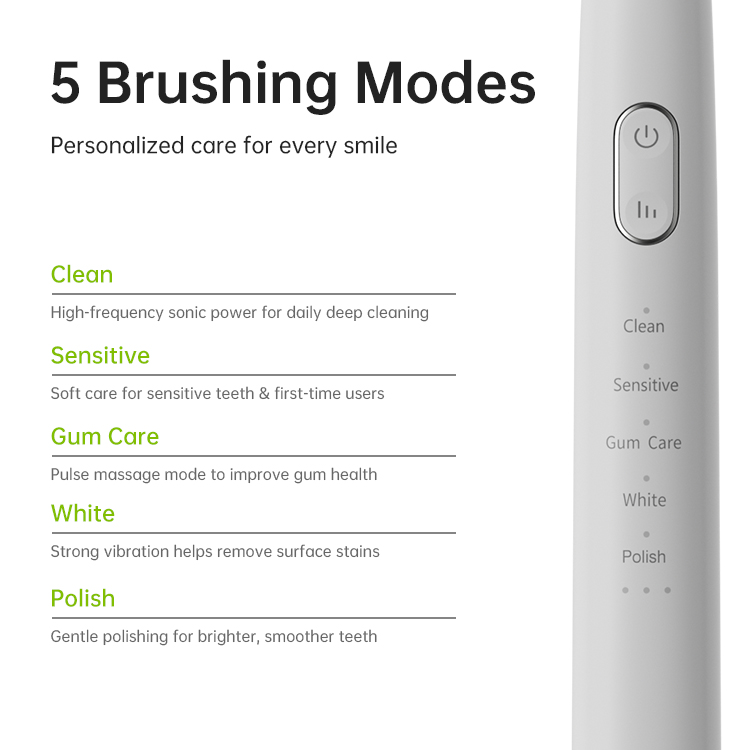

Do the Various Brushing Modes Suit Users with Sensitive Gums and Those Wearing Dentures?

Innovative Features That Make Your Electric Toothbrush Stand Out

How Does Ethical Toothbrush Material Sourcing Contribute to a Sustainable Toothbrush Product?

How Does a Hydro-mechanical Seal Ensure Consistent Spectral Output Optimization in LED Kits?

.jpg)

Motor Overheating Disrupts Oral Microbiome? Critical Alert!

What’s the Difference Between Expensive and Cheap Teeth Whitening light?

Why Is an Orthodontic Jet Tip More Effective with a Multi-pressure Setting Chip?

.jpg)

Is a Fourth July brush the best way to celebrate Texas patriotic brush pride?

Is the Manufacturing Process of Electric Toothbrushes Complicated?

-1-scaled.png)

Why Combine Whitening Tray Manufacturing with Whitening Gel Formula Development?

Complete Analysis of Teeth Whitening Gel Ingredients: Safe Hydrogen Peroxide Levels, Desensitizing Agents & pH Balance

.jpg)

Can Cartoons Improve Brushing Habits?

How does dental suction enhance infection control?

Modern technology in oral care: innovative products and services

Seeking a Toothbrush Sustainable Supplier?

The evolution history of electric toothbrushes