A high-performance UV Sanitizing Component relies not only on advanced ultraviolet technology but also on the quality of its structural materials. When constructed with Medical-grade Material, UV sanitizing systems achieve higher safety standards, durability, and hygiene performance—making them more suitable for professional healthcare, dental, and premium consumer applications.

Using Medical-grade Material ensures that the UV Sanitizing Component does not release harmful substances when exposed to UV radiation, heat, or moisture. This is critical for applications involving personal care devices, oral care tools, and clinical environments where user safety is a top priority.

UV exposure can degrade low-quality plastics over time. Medical-grade Material offers higher resistance to UV-induced aging, discoloration, and micro-cracking, allowing the UV Sanitizing Component to maintain structural integrity and long-term performance.

Medical-grade surfaces are designed to resist bacterial adhesion and biofilm formation. This makes the UV Sanitizing Component easier to clean, more hygienic in daily use.

UV sanitizing systems often operate in humid or enclosed conditions. Medical-grade Material provides superior resistance to moisture, heat, and chemical exposure, ensuring stable operation of the UV Sanitizing Component in demanding environments.

Devices using Medical-grade Material are better positioned to meet international regulatory standards such as ISO, FDA, CE. This simplifies certification pathways for products integrating a UV Sanitizing into healthcare, dental, and professional-grade equipment.

From a commercial perspective, combining a UV Sanitizing with Medical-grade Material construction enhances product credibility, supports premium positioning.

A UV Sanitizing built with Medical-grade Material delivers more than just disinfection—it provides safety assurance. For B2B manufacturers and OEM/ODM partners, this combination creates higher-value products that meet both technical. Contact us

How to Judge Whether a factory’s R&D capabilities Is Strong?

.jpg)

Head Detachment During Lip Abrasions – Design Fault?

Effective Water Flosser Disinfection Methods & Smart OEM Design Solutions

.jpg)

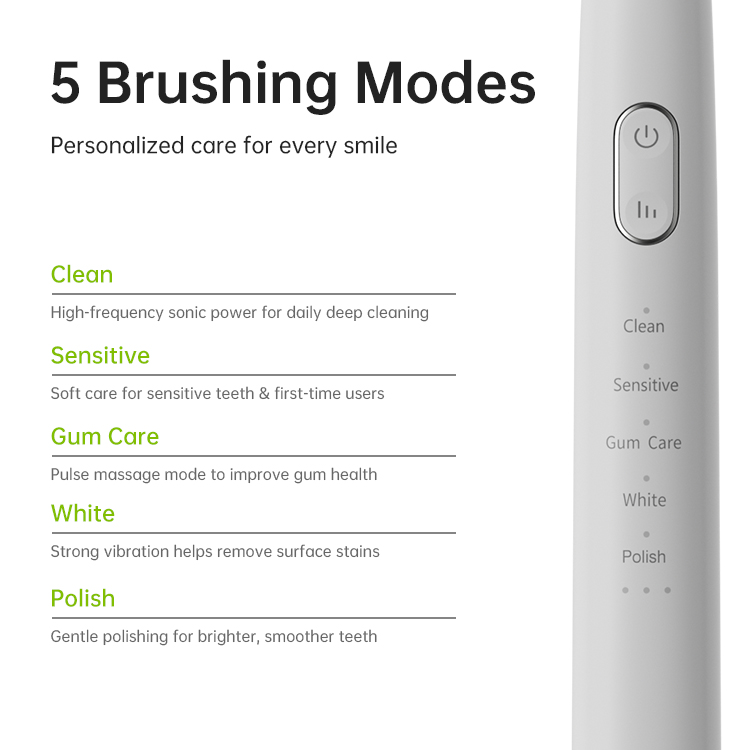

Pursuing the ultimate cleaning experience?

Does an orthodontic brush simplify braces care?

Personalized Christmas Gifts for Employees: Electric Toothbrush Ideas

.jpg)

Corporate Wellness Electric Toothbrush Pack | Bulk Oral-Care Gift Supplier

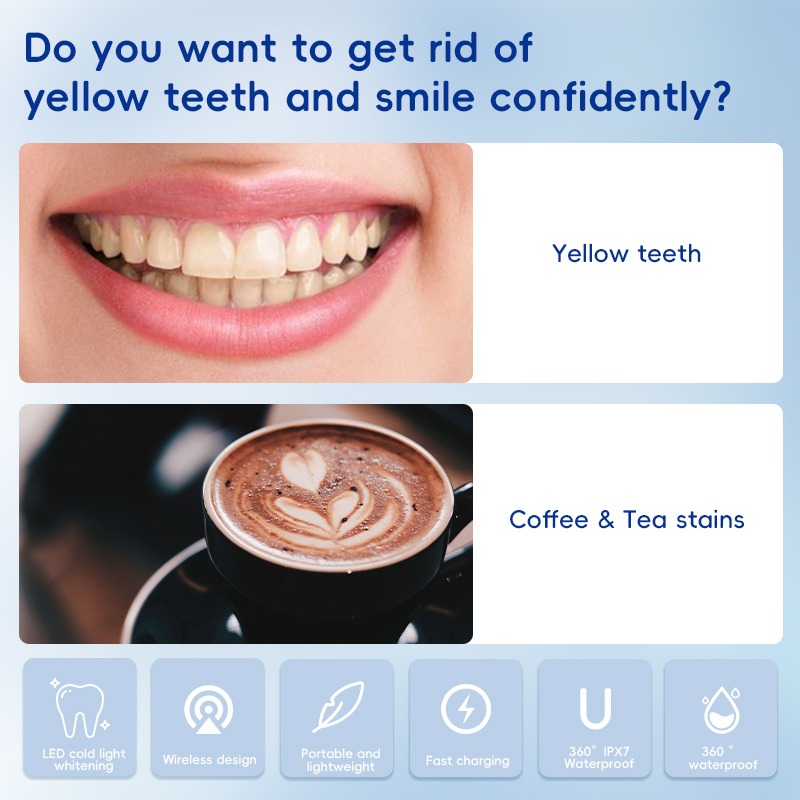

Want Hollywood smiles? Dental veneers via cosmetic dentistry — worth it?

What is the Function of the Gravity Ball Design of the water Flosser?

Capitalizing on the LED Oral Care Boom: Essential Market Insights for Brands

.jpg)

The Potential of the Oral Care Market in Southeast Asia: Trends & Opportunities for Brands

Why Conduct a Pressure Decay Test on Units Featuring Vortex Chamber Technology?

Should I Brush My Teeth Again After Using LED Teeth Whitening Kits?

One-Stop OEM Factory for Electric Toothbrushes, Water Flossers & Whitening Kits

.jpg)

Motorized Toothbrush Testing & Overall Solutions | Quality Assurance

Best Electric Toothbrush Deals in San Francisco?