Electric toothbrush for sensitive teeth OEM development is driven by a clear market demand: delivering effective plaque removal while minimizing stimulation to enamel and gums. For B2B oral care brands, this segment requires a different engineering logic compared to standard or high-power toothbrush models.

Sensitive teeth products are not simply “lower power” versions of standard toothbrushes. Instead, they are engineered to manage vibration transmission, pressure response, and user adaptation.

From a market perspective, sensitive-oriented models are frequently positioned for long-term daily use rather than short-term whitening or deep-cleaning campaigns. Therefore, stability, comfort, and consistency become core performance indicators.

OEM development for sensitive teeth emphasizes vibration control rather than raw frequency. Manufacturers typically adjust amplitude ranges, waveform smoothness, and motor startup behavior.

Soft-start vibration profiles are commonly integrated. Instead of reaching full intensity immediately, vibration ramps up gradually, reducing initial discomfort for users with exposed dentin or gum recession.

Additionally, pressure feedback logic is calibrated conservatively. Rather than stopping abruptly, vibration intensity is reduced smoothly when excessive pressure is detected.

OEM electric toothbrush platforms designed for sensitive users can be reviewed here:

👉 https://www.powsmart.com/electric-toothbrush/

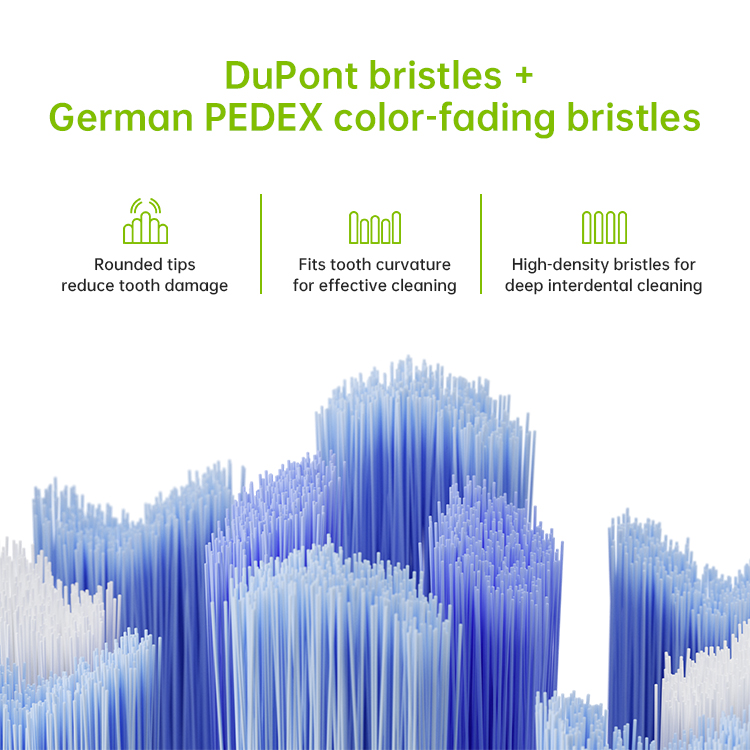

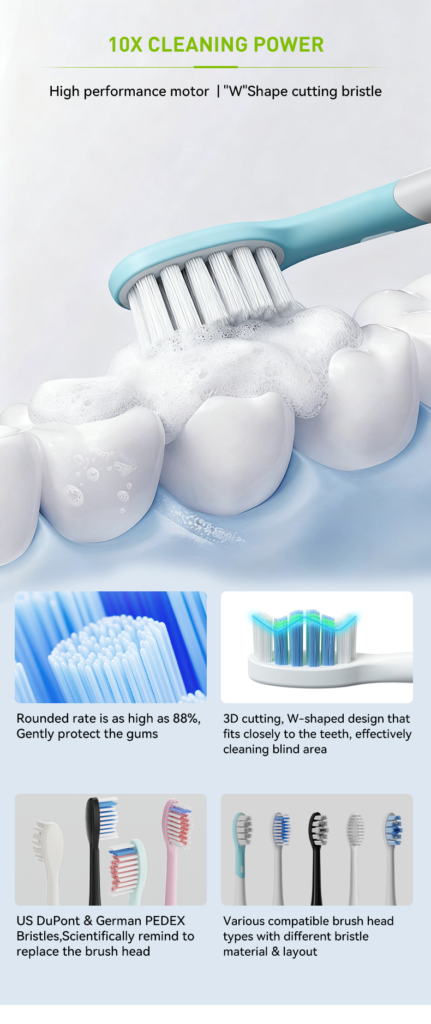

Sensitive teeth performance depends heavily on brush head compatibility. OEM suppliers coordinate vibration patterns with soft bristle configurations to avoid aggressive contact.

Internal testing often focuses on vibration dispersion at the brush head tip rather than handle output alone. This ensures cleaning efficiency is maintained without increasing localized irritation.

Dental care professionals consistently emphasize gentle, controlled brushing motions for sensitive teeth maintenance, supporting this engineering approach.

External reference: https://www.ada.org/

From a production standpoint, sensitive-oriented models require tighter tolerance control. Even minor deviations in motor balance or shaft alignment can increase vibration harshness.

OEM quality control processes typically include low-intensity mode stability testing, noise measurement, and long-duration vibration consistency checks. These tests ensure that comfort performance remains consistent across production batches.

Battery management systems are also optimized to deliver smooth power output. Voltage fluctuation can create uneven vibration, which is particularly noticeable in sensitive-use products.

Sensitive teeth products are often marketed with comfort-related claims. Therefore, OEM manufacturers assist brands in preparing compliant documentation aligned with regional regulations.

Instruction manuals and labeling emphasize correct usage frequency and pressure guidance. This reduces misuse risks and supports long-term user satisfaction.

Global dental organizations such as the FDI highlight the importance of gentle daily cleaning routines, reinforcing the relevance of sensitivity-focused designs.

External reference: https://www.fdiworlddental.org/

Working with a specialized electric toothbrush for sensitive teeth OEM allows brands to enter this segment without building proprietary vibration control systems internally. Mature OEM platforms shorten development cycles while ensuring stable performance.

For brands planning multi-model product lines, sensitivity-focused variants also serve as complementary offerings, expanding market coverage without excessive R&D investment.

.jpg)

Is the Middle-Aged and Elderly Consumer Group a Potential Market for Electric Oral Hygiene Products?

.jpg)

Electric Toothbrush for Beauty Box Subscription | Personalized Oral Care

What are the advantages of ultraviolet sterilization water flosser?

.jpg)

Thanksgiving Employee Gift Sets Electric Toothbrush Seattle | Supplier

What’s the Best Electric Toothbrush for Sensitive Gums in Boston?

ISO 13485 Certification Interpretation: How Do Electric Toothbrush Meet Medical Device-Grade Production Standards?

.jpg)

Cavity Risk from Taste Residue?

.jpg)

Considering Whitening Kit Private Label?

Tips for Preventing Mold in Water Flosser Tanks

.jpg)

Silicone Electric Toothbrush | Soft Bristles & Gentle Deep Cleaning OEM

How Does a Teeth Whitening Gel OEM Partner with a Whitening Strips Manufacturer for Holistic Kits?

Environmental Protection and Sustainability of Electric Toothbrushes

.jpg)

Will You Get a Transparent Toothbrush Cost Breakdown?

.jpg)

Does Noise Increase Signal Vibration Inconsistency?

.jpg)

Gum-Care Whitening Device | Gentle LED Oral Care OEM Solution

.jpg)

Do Bronx toothbrush deals include NYC replacement heads?