In modern whitening product evaluation, Surface Reflectance and Subsurface Scattering measurements provide a more complete understanding of how teeth interact with light during and after treatment. For B2B manufacturers developing gels, LED systems, and professional whitening devices, these optical data points move efficacy assessment beyond simple shade comparison toward a scientifically grounded evaluation of true visual improvement.

Surface Reflectance data helps manufacturers distinguish between temporary surface-level brightness and long-lasting whitening effects. By measuring how much light is reflected at the enamel surface, R&D teams can identify whether results are cosmetic or structurally meaningful.

Subsurface Scattering captures how light penetrates and diffuses within enamel and dentin layers. This insight is critical for evaluating whitening systems that aim to enhance natural translucency rather than merely increasing surface luminance.

By correlating Surface Reflectance with Subsurface Scattering data, manufacturers can evaluate how gel composition, peroxide release rates, and light activation interact. This supports data-driven optimization of both chemical and optical components in whitening systems.

Optical metrics reduce reliance on subjective visual grading. Standardized measurement of reflectance and scattering enables consistent efficacy evaluation across different labs, clinical sites, and production batches.

Quantified optical improvements provide credible evidence for efficacy claims. When manufacturers can demonstrate improvements in both Surface Reflectance and Subsurface Scattering, whitening performance claims become more defensible and transparent to professional buyers.

As the industry moves toward more advanced optical validation, integrating these data sets positions manufacturers at the forefront of innovation. This approach aligns with emerging expectations for precision, traceability, and performance differentiation in professional whitening solutions.

For B2B whitening manufacturers, incorporating Surface Reflectance and Subsurface Scattering data significantly elevates the accuracy of efficacy evaluations. These optical insights provide a deeper, more reliable foundation for product development, quality control, and global market competitiveness. Contact us

.jpg)

.jpg)

Why is Whitening Kit Ingredients Custom Vital for Producing SGS Tested Whitening Kit?

.jpg)

Is a Reliable Water Flosser Pump Supplier Key to Developing a High-Pressure Flosser?

As Young People Pay More Attention to Their Teeth, What New Trends Are Emerging in Oral Care?

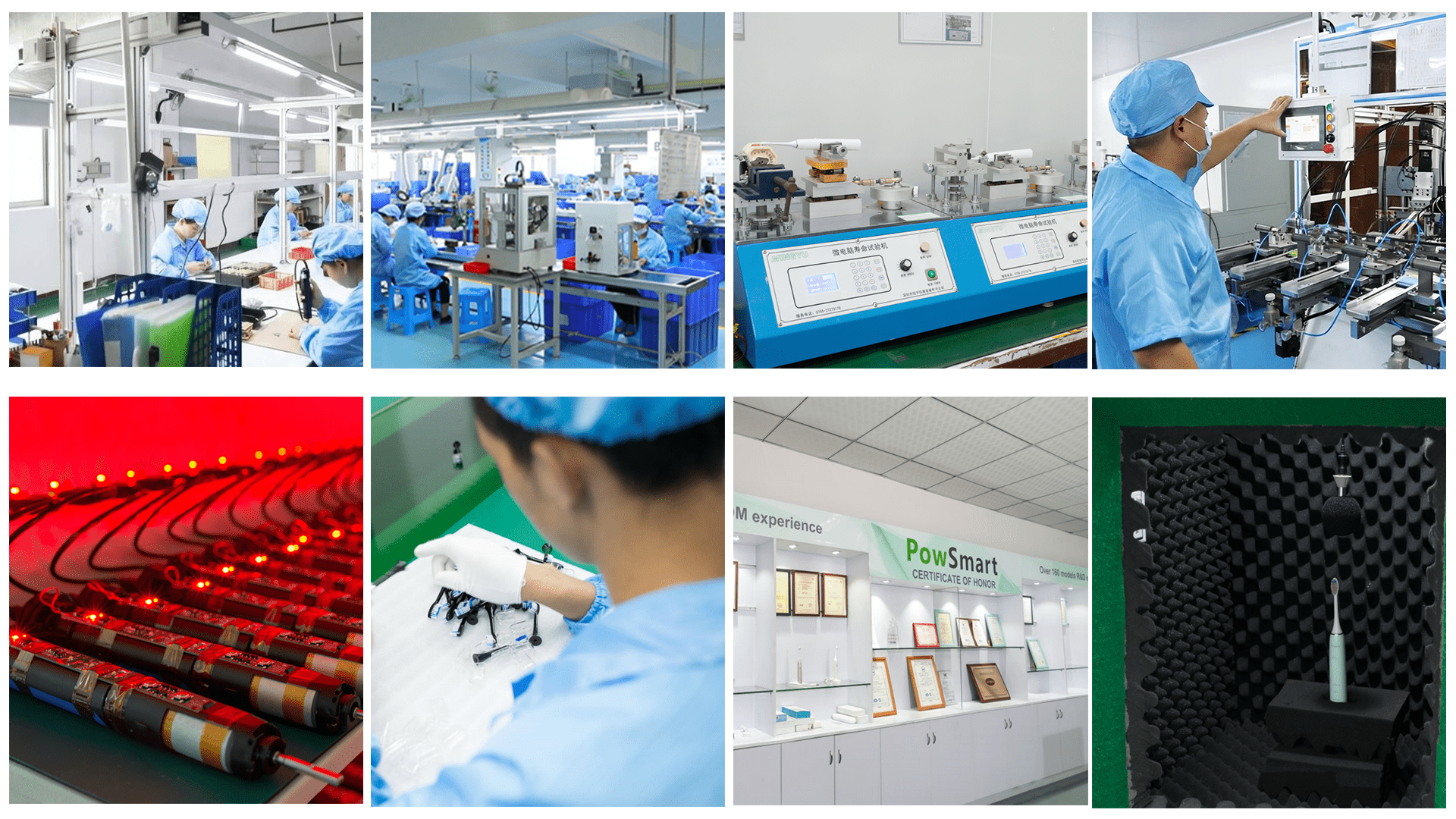

Why Choose Us? 5 Reasons to Trust the Manufacturer of Oral Care Products

How to Repair an Electric Toothbrush – Answers from Manufacturers

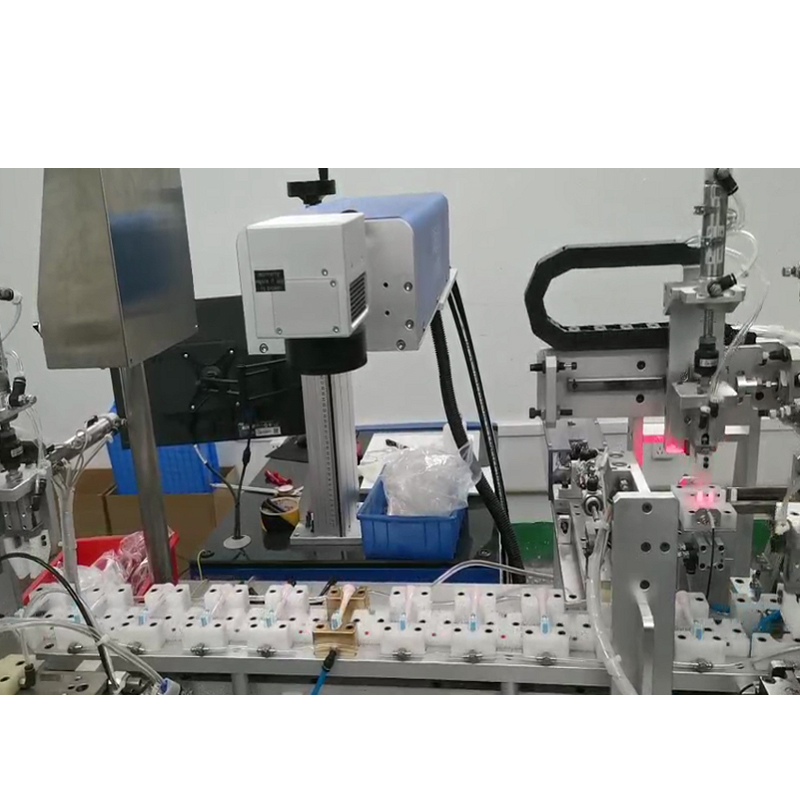

Does Your Sonic Vibration Core Require a Reliable PCB Assembly Service?

Why a Hindi brushing guide is essential for your First-time user guide

How Can Gradient Color Injection Molding Technology Improve the Attractiveness of Electric Toothbrushes?

.jpg)

Electric Toothbrush Shipping Solutions for OEM & Wholesale Export

Can Smart App Connectivity Enhance the User Feedback from Pressure Sensor Calibration Data?

.jpg)

Smart Toothbrush for Professionals | Tech Lifestyle Care

Is Your Accelerated Whitening Solution Backed by Full Aesthetic Device Compliance?

.jpg)

Water Flosser competitive Features That Cause Premium Pricing: What Brands Should Look For in Manufacturing

.jpg)

Dental Care Electric Toothbrush for Grandparents

.jpg)

Travel Electric Toothbrush with Case – Compact & Rechargeable B2B Supply

.jpg)

USB-C Water Flosser Wholesale | Fast-Charging Oral Irrigator Distributor