A toothbrush factory audit checklist is a critical tool for importers, brand owners, and OEM buyers who want to reduce supply-chain risks and ensure consistent product quality. As electric toothbrush demand grows globally, factory audits have become an essential step before mass production or long-term cooperation.

When sourcing from overseas manufacturers, visual inspections alone are not enough. Instead, a structured audit process helps buyers verify whether a factory can meet quality, compliance, and capacity requirements. Moreover, audits reduce the likelihood of shipment delays, product recalls, and regulatory violations.

Because toothbrushes are consumer health-related products, buyers must confirm that suppliers follow strict manufacturing and testing standards. Therefore, a standardized audit checklist is widely used by professional procurement teams.

Buyers should confirm whether the factory operates under ISO-based quality systems. Document control, incoming material inspection, and traceability procedures should be clearly defined. Additionally, internal quality audits should be conducted regularly.

A reliable factory should demonstrate stable production lines, skilled operators, and realistic output planning. Buyers should also verify whether peak-season capacity aligns with forecasted order volumes.

You can review typical electric toothbrush production setups here:

👉 https://powsmart.com/products/electric-toothbrush

Motors, batteries, and brush heads are key components. Therefore, buyers should check approved supplier lists and incoming inspection records. Stable upstream partnerships reduce the risk of inconsistent quality.

A professional audit checklist must include compliance verification. CE, FCC, RoHS, and FDA-related documentation should be available and up to date. Furthermore, labeling and user manuals must align with target market regulations.

For global oral-care standards and guidance, buyers may consult:

👉 https://www.ada.org

Many international brands now require audits covering labor conditions, workplace safety, and environmental responsibility. Proper training records, fire safety measures, and protective equipment should be verified during on-site visits.

After completing the audit, buyers should summarize findings, identify risks, and define corrective action plans. A transparent supplier will actively cooperate in addressing issues, which is often a strong indicator of long-term reliability.

Using a structured toothbrush factory audit checklist enables B2B buyers to make informed sourcing decisions and build stable partnerships. By systematically evaluating quality systems, capacity, and compliance, buyers can reduce operational risk and protect their brand reputation. Ultimately, a thorough toothbrush factory audit checklist is an essential foundation for successful electric toothbrush sourcing.

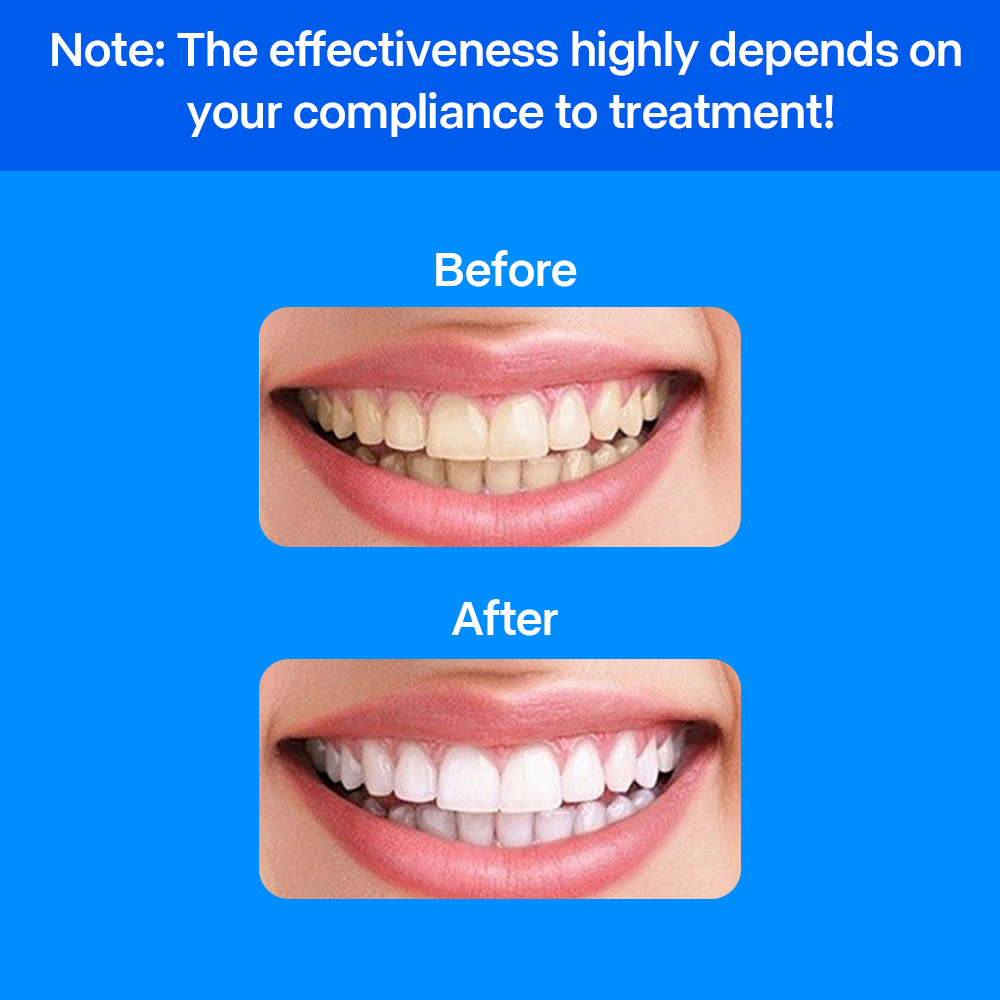

Hydrogen Peroxide vs. Carbamide Peroxide: Which Whitening Gel Formula is Right for You?

.jpg)

Long Battery Life Electric Toothbrush OEM Supplier

How Can Smart App Connectivity Boost User Engagement Through Bluetooth App Integration?

.jpg)

The Hidden Risks of Over-Engineered Water Flossers: Consequences of Excessive Pulse Frequency

Are Oral Care Products Suitable for TK Small Businesses?

.jpg)

Electric Toothbrush with Long Battery Cycle Durability, Waterproof Design & Advanced PCB Technology

How Does Controlled Enamel Micro-abrasion Work With Chromophore Targeting Gel for Safer Whitening?

.jpg)

What Tests Are Essential for a High-Quality Water Flosser Before Shipment?

.jpg)

Rechargeable Electric Toothbrush OEM | Custom B2B Manufacturing

Five Key Factors to Enhance the Competitiveness of Water Flosser Products

Whitening Sensitiveh Promote Whitening and Sensitive Populations

SF toothbrush deals vs. San Francisco sale — which is better?

.jpg)

Hospital Use Electric Toothbrush Bulk Supply | Professional Dental Hygiene Solution

Development of New Functions for Oral Irrigators: How to Meet User Needs?

Why a Surat luxury toothbrush demands a Gold plated toothbrush finish

.jpg)

Father’s Day Gift Electric Toothbrush for Texas Dad