When it comes to consumer safety in oral care devices, waterproof failure isn’t just a mechanical flaw—it could be a direct cause of material toxicity. Many assume that as long as a product functions electrically, it’s safe. However, water intrusion can trigger chemical degradation in materials not designed to withstand prolonged moisture exposure. For OEMs and B2B buyers, understanding the correlation between waterproof integrity and toxic material leaching is crucial to both compliance and brand reputation.

Traditionally, waterproofing is associated with protecting internal components like motors or batteries. However, in modern electric toothbrushes, water can infiltrate and compromise:

When waterproof failure occurs—due to poor IP sealing, failed ultrasonic welding, or loose assembly—the materials not intended for water exposure may begin to degrade, leading to the release of harmful substances into contact areas like grip zones or brush necks.

The connection between waterproof failure and material toxicity is chemical in nature. Prolonged moisture intrusion can:

Especially in high-temperature environments like bathrooms, this degradation process intensifies. Over time, users may unknowingly be exposed to irritants or long-term carcinogens through direct skin or oral contact. Company web:https://www.powsmart.com/product/electric-toothbrush/

Regulations such as REACH, RoHS, and FDA material compliance clearly restrict the presence of certain heavy metals, phthalates, and BPA in consumer-facing components. However, these tests often assume “dry use” conditions.

If a product experiences waterproof failure, the material’s chemical behavior under “wet conditions” could render it non-compliant. This puts B2B brands at risk of:

The origin of most waterproof breaches can be traced to:

These are often overlooked during cost-cutting or rapid scaling. A single failed batch can result in hundreds of devices with compromised enclosures.

To avoid this cascading risk, manufacturers should adopt robust design-for-waterproofing strategies, including:

OEM partners should also be transparent about their material sourcing and provide full material safety data sheets (MSDS) for each component.

At our production facilities, we run multi-stage testing, including:

All components used are pre-certified to meet global toxicity safety standards, even in failure scenarios. This gives our OEM clients confidence—not just in initial performance—but in lifecycle safety.

The link between waterproof failure and material toxicity is often invisible—until customer complaints or lawsuits arise. For B2B brands and procurement teams, selecting the right manufacturing partner means choosing one who proactively tests for failure points and material safety beyond minimum specs.

Looking to audit your current waterproof design or material selection? Reach out to our engineering team for a risk assessment tailored to your product line.

Deep Clean Interdental Electric Toothbrush Manufacturing Solutions

Need Packaging Customization Service for Products Containing a Lithium Battery Pack?

How Do Custom Vibration Modes Rely on a Versatile Multi-mode Chip Solution?

How a Gentle senior brush protects Sensitive elderly gums

.jpg)

teeth whitening kit wholesale | Professional Whitening Kit Bulk Supplier

.jpg)

ABS Nozzle Smart Molding & Cycle Optimization | Manufacturing Efficiency

Does Gum Massage Mode Truly Boost the Receding Gums Solution Effectiveness?

A Guide to Consumer Cognitive Education for Water Flosser Brands

.jpg)

Bulk Electric Toothbrush San Francisco

.jpg)

Is Dental tourism viable for Kirkland services?

How Does an LED Whitening Light Withstand a Pressure Decay Test for Durability?

How to Pick the Right Water Flosser for Your Oral Health: Answers from an Oral Irrigator Manufacturer

.jpg)

Battery Bloating with Jaw Fatigue – Coincidence?

.jpg)

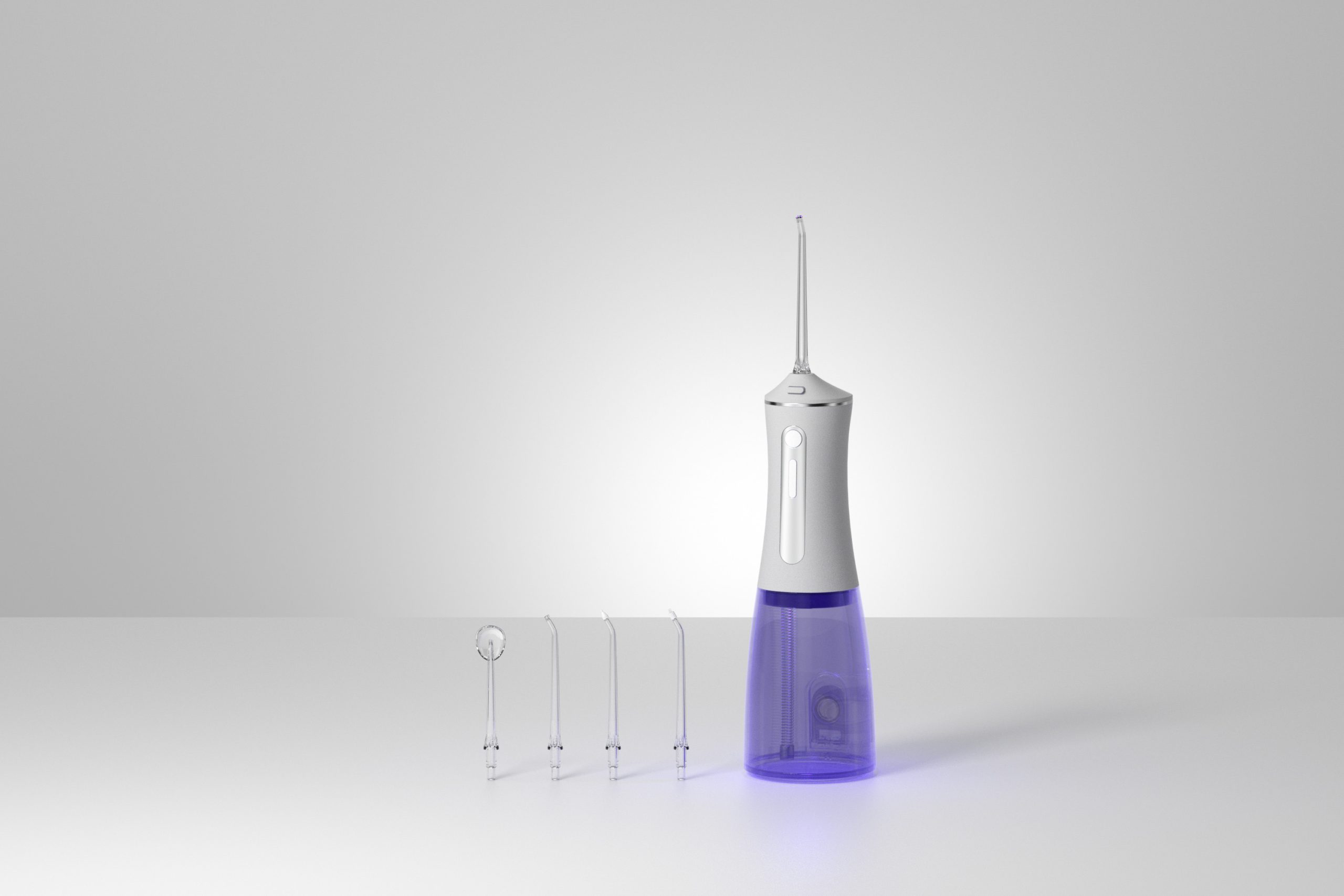

Benefits of Travel-Friendly Water Flosser Design

How to Enhance Brand Competitiveness by Segmenting the Market Demand for Teeth Whitening

Why is There Such a Big Price Difference Between Teeth Whitening Kits on the Market?