In practice, a tooth’s enamel vulnerability is closely tied to persistent staining residuals. Meanwhile, smart mode switching—allowing a device to adapt its cleaning stages—can effectively reduce pigment buildup and prevent secondary enamel erosion. In the following six sections, we’ll analyze their interconnection and offer optimization strategies.

First, even minute pigment residues on enamel can:

Thus, residual staining not only mars appearance but undermines enamel strength at the microscopic level.

Next, pigment residues interact with the mouth’s acid–base balance:

Controlling residual stains is therefore critical to preserving intact enamel.Company web:https://www.powsmart.com/product/electric-toothbrush/

To tailor cleaning intensity and protect enamel, devices should implement smart mode switching:

This smart sequencing maximizes pigment removal while minimizing cumulative enamel wear.

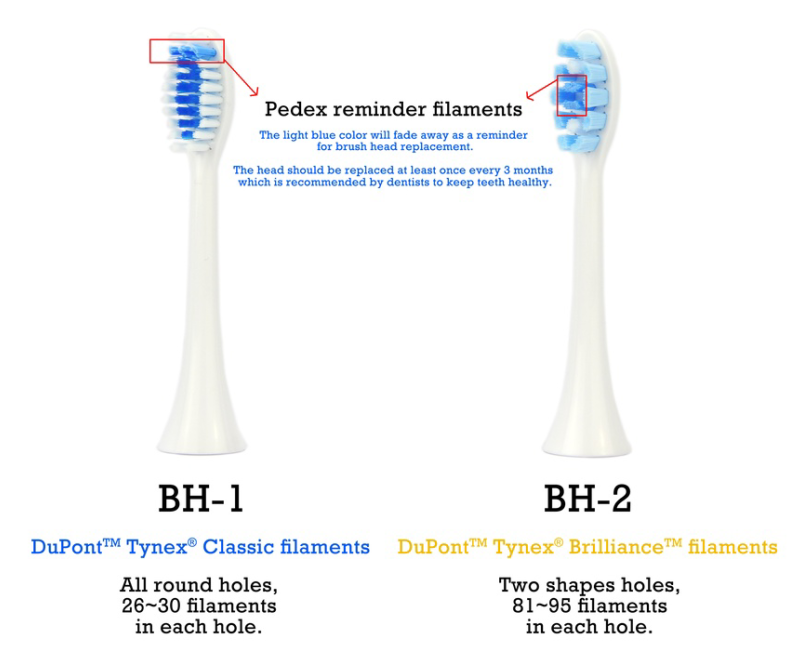

In addition, brush and polish head construction matters:

Innovative head materials and structures greatly enhance cleaning performance and enamel protection.

Beyond hardware and software, effective use requires guided workflows:

A holistic, guided experience ensures that smart mode switching is both efficient and user-friendly.

Finally, looking ahead:

Ongoing innovation will enable B2B partners to deliver faster, gentler, and smarter stain-removal solutions that safeguard enamel health.

Conclusion

Enamel vulnerability is intrinsically linked to staining residuals. By leveraging smart mode switching, advanced head materials, guided workflows, and intelligent sensing, B2B manufacturers can effectively eliminate pigments while protecting enamel integrity—earning lasting trust from partners and end users alike. For custom stain-control and enamel-preservation strategies, please contact our technical team!

.jpg)

Electric Toothbrush Bulk for Wellness Programs | B2B Oral Care Solutions

How to Ensure That a Factory’s Quality Control Process is Strict and Standardized

Are You a Micro Motor Supplier Also Offering PCB Assembly Service?

Can a Wireless Charging Coil Optimize the Performance of a Long-Lasting Battery?

.jpg)

How to Choose a Professional ultraviolet sterilized water flosser Manufacturer?

Can an Orthodontic Jet Tip Benefit from a Smart Multi-pressure Setting Chip?

Is Whitening Kit Certification Necessary for Marketing a Portable Whitening Kit Globally?

The Advantages of the Brush Head Subscription Service for Oral Care Brand Growth

.jpg)

Oral Irrigator with Modularized Design Product | Diversification for Custom Care

.jpg)

Power Toothbrush Process Optimization: Achieve 50% Faster Cleaning with Smart Brushing Algorithms

.jpg)

Ergonomic Design Electric Toothbrush OEM Solutions

.jpg)

Silent Electric Toothbrush for Hotels

Why Is a Precise Pressure Control System Dependent on an Accurate Flow Rate Calibration Tool?

Collaborative Development of Red and Blue Light Teeth Whitening Gel Formulas: How to Increase Whitening Efficiency by 3 Times?

.jpg)

Best Smart Toothbrush Features for Bulk Buyers: A Supplier’s Guide

Which Charging Method for Electric Toothbrushes Is Better and Has a Lower Charging Failure Rate?