In today’s high-tech products, intermittent LCD Glitches and recurring Sensor Errors can undermine user confidence and lead to costly returns. Whether you’re producing medical devices, industrial controllers, or consumer electronics, understanding how these faults arise and how to remedy them quickly is essential. This post walks you through the root causes, diagnostic techniques, repair steps, and preventive measures to tackle LCD glitches and sensor errors effectively.

Firstly, LCD displays and onboard sensors often serve as the primary interface between machine and operator. LCD Glitches—such as flickering segments, ghost images, or unresponsive pixels—can obscure critical data readouts. Similarly, Sensor Errors—including spurious readings, calibration drift, or complete signal loss—can disrupt feedback loops, trigger false alarms, or halt automated processes. Together, these issues not only degrade product performance but also raise maintenance costs and damage your brand reputation.

Moreover, LCD Glitches typically stem from one or more of the following factors:

By isolating these causes, you can target the precise area—whether electrical, mechanical, or software—that needs correction.Company web:https://www.powsmart.com/product/electric-toothbrush/

Transitioning to sensors, diagnosing Sensor Errors requires a systematic approach:

Armed with this data, you can distinguish between genuine sensor hardware faults and configuration or environmental issues.

Importantly, LCD Glitches and Sensor Errors can exacerbate one another. For example, unstable power rails may cause both display flicker and noisy sensor readings simultaneously. Likewise, a loose ground connection can introduce ground loops that manifest as display artifacts and erroneous sensor measurements. Recognizing these cross‑domain interactions helps you adopt holistic remedies rather than isolated fixes.

To resolve these problems effectively, follow these best practices:

Finally, preventing LCD Glitches and Sensor Errors from returning requires continuous improvement:

By combining rigorous design, thorough testing, and smart maintenance strategies, you can ensure your products remain reliable, user‑friendly, and free of LCD glitches and sensor errors.

Conclusion

LCD Glitches and Sensor Errors can undermine even the most sophisticated products if left unchecked. However, with a structured diagnostic process, targeted repairs, and strategic preventive measures, manufacturers can eliminate these faults and uphold the highest reliability standards. Ready to optimize your device performance? Contact our engineering team to explore tailored solutions for your display and sensor challenges.

Can a Bangalore AI toothbrush boost your Efficient brushing tech routine?

Complete Analysis of Teeth Whitening Gel Ingredients: Safe Hydrogen Peroxide Levels, Desensitizing Agents & pH Balance

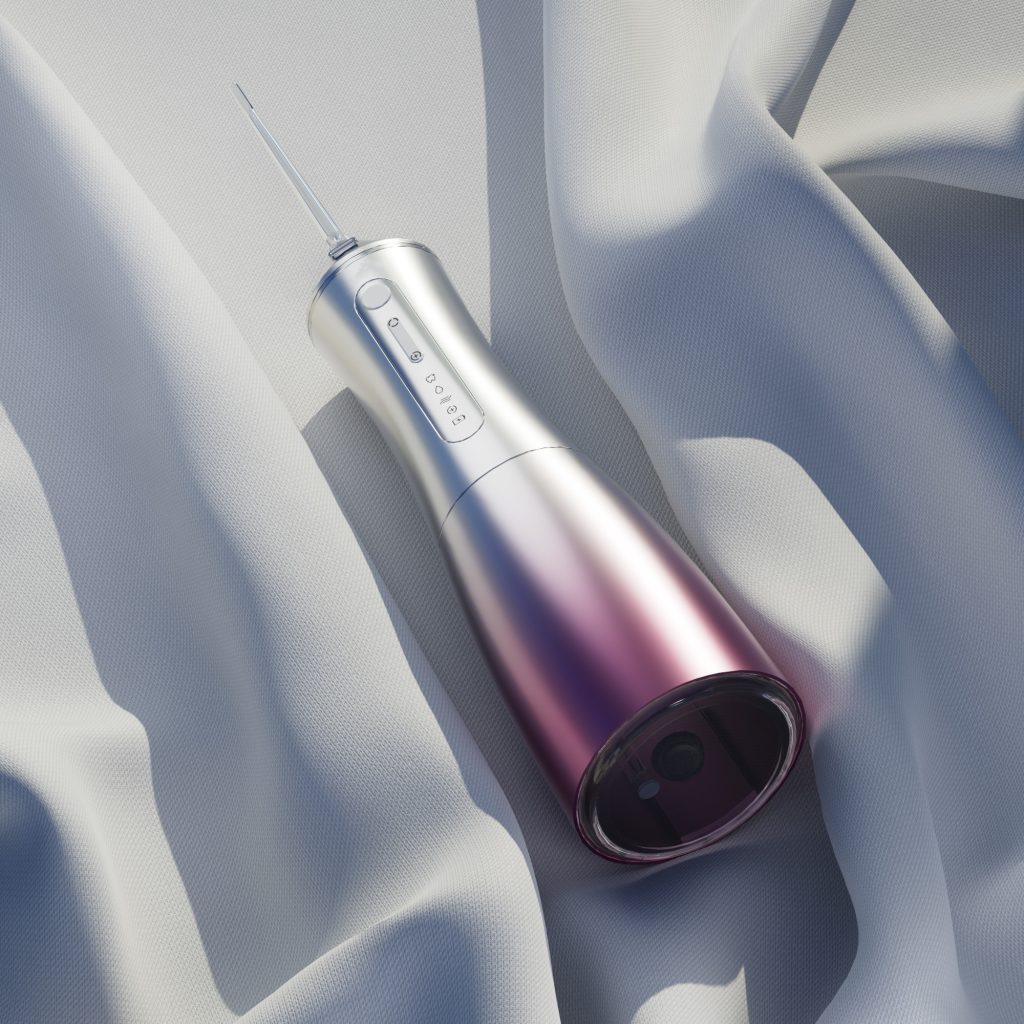

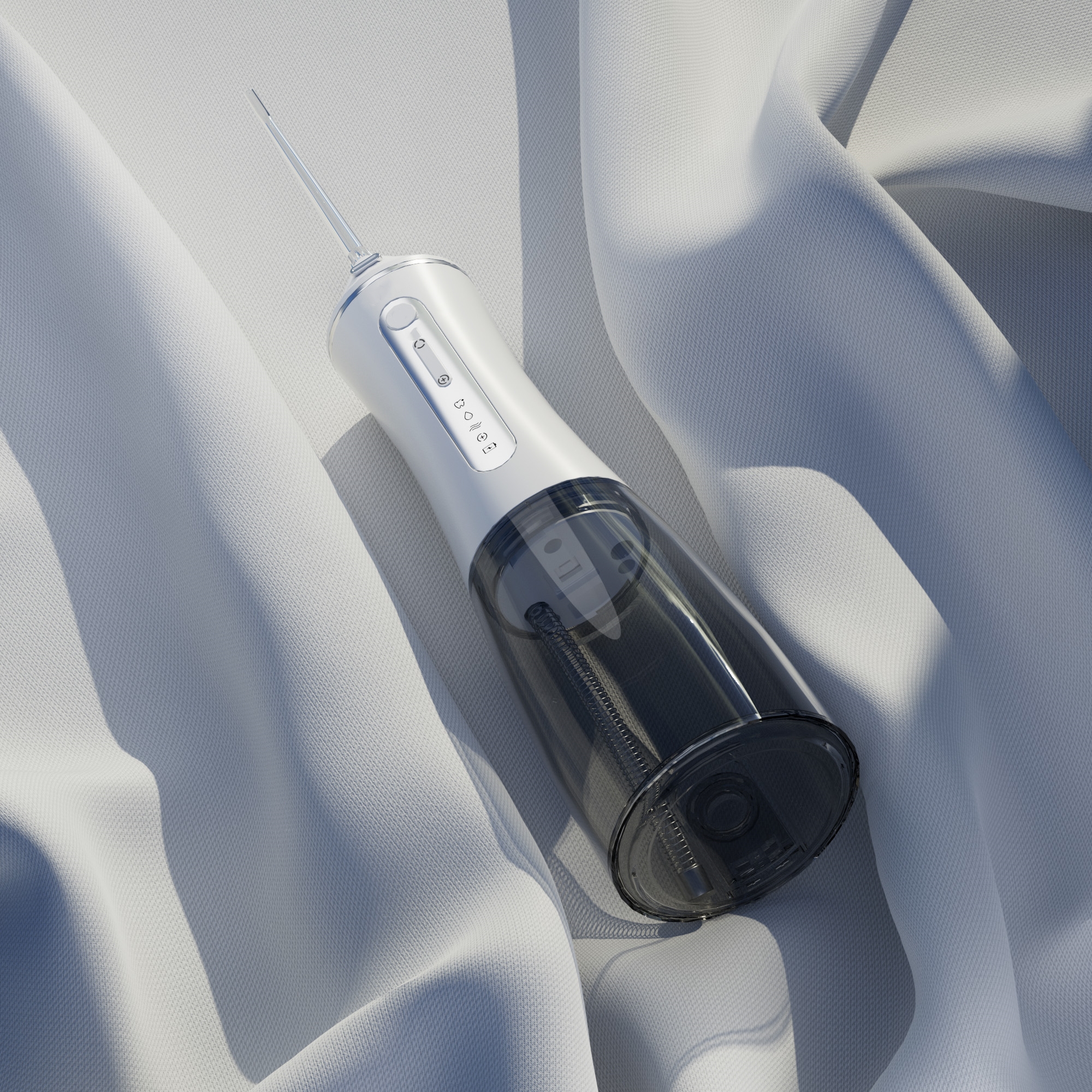

What are the advantages of ultraviolet sterilization water flosser?

Travel Water Flosser Design: Power Compatibility, Storage & Waterproofing

Scientific Oral Care: An All-Inclusive Guide to Preventing Oral Diseases

Beginner’s Guide to Water Flosser Pressure Settings

.jpg)

Are Filter Degradation and Voltage Drops Linked?

Common quality problem with electric toothbrushes

Should You Try The Take-Home Whitening Kit?

Custom Your Electric Toothbrush or Water Flosser Brand Now!

Children’s Oral Care: Developing Good Oral Habits at an Early Age

.jpg)

Gift for Software Engineer Electric Toothbrush Bangalore

.jpg)

Is Your Kids’ Electric Toothbrush Too Loud?

.jpg)

How Dangerous Are Jet Instability and Power Surges?

Ideal Pressure Settings for Sensitive Gums: Dentist Recommendations for Water Flosser Users

Modern technology in oral care: innovative products and services