The Water Flosser Manufacturing process plays a pivotal role in creating Eco-Friendly Oral Products that meet both consumer demands and environmental standards. In a world increasingly focused on sustainability, manufacturers are finding innovative ways to incorporate eco-friendly materials and energy-efficient technologies into the production of water flossers.

The foundation of an Eco-Friendly Oral Product begins with the choice of materials. By using biodegradable, recyclable, or renewable materials for the water flosser body and components, manufacturers can significantly reduce environmental impact. The Water Flosser Manufacturing process must prioritize sustainable sourcing to ensure that the product is both functional and eco-conscious.

Energy efficiency is key to creating an Eco-Friendly Oral Product. During the Water Flosser Manufacturing process, incorporating energy-saving features—such as rechargeable batteries or low-energy consumption motors—can drastically reduce the product’s carbon footprint. These innovations contribute to a more sustainable product that aligns with the growing demand for eco-conscious consumer goods.

Sustainable packaging is another critical aspect of producing an Eco-Friendly Oral Product. By using recycled or recyclable packaging materials, such as paper, cardboard, or biodegradable plastics, manufacturers can minimize waste and reduce their overall environmental impact. The Water Flosser Manufacturing process should prioritize sustainable packaging designs to appeal to environmentally conscious consumers.

Water flossers are designed to provide an effective and eco-friendly alternative to traditional string floss. However, their impact can be further minimized by reducing water waste during the Water Flosser Manufacturing process. By improving water efficiency in the design, manufacturers can ensure that the product remains environmentally friendly. Additionally, using eco-friendly plastics or alternative materials can further reduce plastic waste associated with the product.

Designing a product with its entire lifecycle in mind is crucial for creating an Eco-Friendly Oral Product. The Water Flosser Manufacturing process should incorporate easy-to-recycle materials that allow the consumer to dispose of the product responsibly at the end of its life. By making the water flosser’s parts modular and recyclable, manufacturers can help reduce landfill waste and contribute to a circular economy.

To establish a true eco-friendly product, certification from recognized environmental standards, such as the Energy Star label or the EU Ecolabel, is essential. During Water Flosser Manufacturing, adhering to these certifications not only proves the product’s sustainability but also boosts consumer trust. These certifications provide a clear and reliable indication of the product’s commitment to environmental responsibility.

The Water Flosser Manufacturing process offers ample opportunities to create truly Eco-Friendly Oral Products that meet the demands of both environmentally conscious consumers and industry regulations. By focusing on sustainable materials, energy efficiency, eco-friendly packaging, and recyclability, manufacturers can lead the way in producing oral care products that benefit both consumers and the planet. Contact us

.jpg)

How Does a Hydro-mechanical Seal Ensure Consistent Spectral Output Optimization in LED Kits?

.jpg)

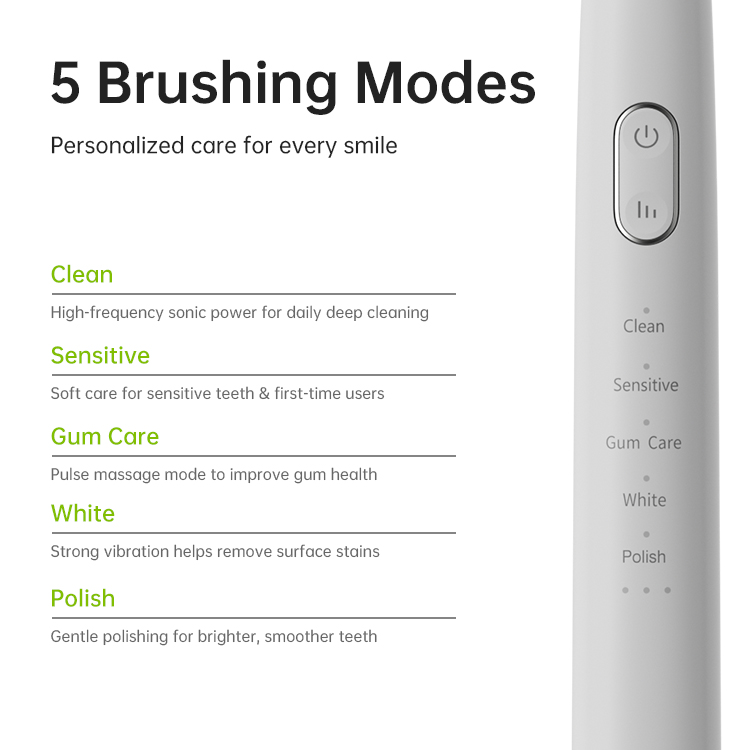

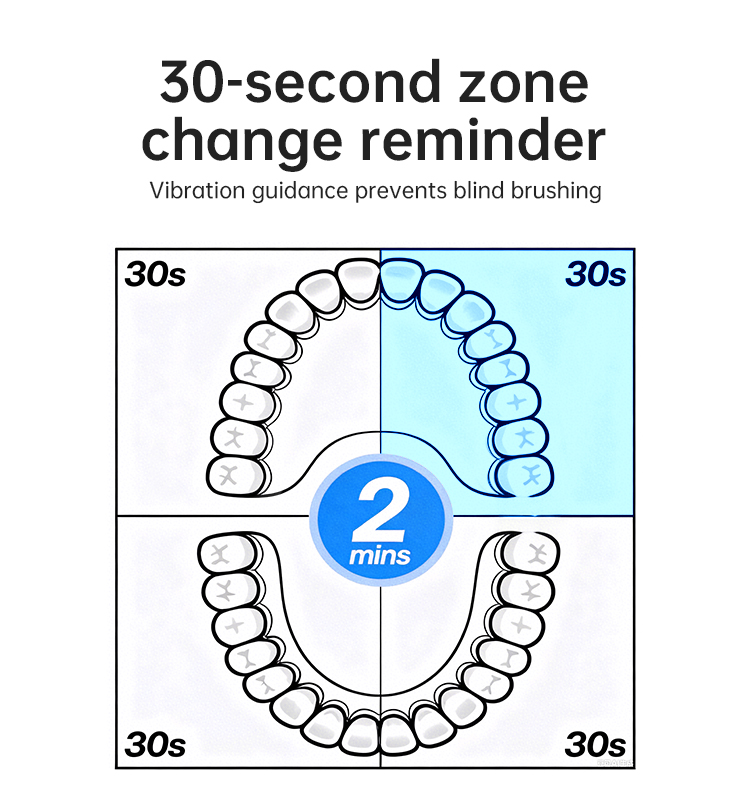

How Does a Toothbrush with Timer Elevate a Smart Oral Care Device?

How Does an Accelerated Whitening Formula Work with a Built-in Timer Function?

.jpg)

Toothbrush Supplier for Amazon Sellers

Can Sonic Wave Technology Benefit from a Motor Efficiency Upgrade?

Why Is Turbine Impeller Design Key to Safe Oral Mucosa Barrier Protection in Flossers?

Does the Efficiency of a Motor Controller IC Directly Impact Battery Life Optimization?

.jpg)

Which Electric Toothbrush is Best for Kids in Chicago?

.jpg)

electric toothbrush for dental hygiene kits

Is a High-Pressure Water Pump Effective Without a Robust Leak-Proof Valve?

.jpg)

Best Electric Toothbrush for Kids in Chicago

How Does a Gravity Feed System Enable a Truly Cordless Portable Design?

.jpg)

Electric toothbrush with soft bristles wholesale

-3-scaled.png)

Are You a Teeth Whitening Kit Manufacturer Serving the Beauty Salon Supply Industry?

.jpg)

Need Chicago repair service during Chicago holiday deals?

.jpg)

multi-mode electric toothbrush supplier