When it comes to Teeth Whitening Syringe OEM production, quality assurance is paramount. A Safe Teeth Whitening Supplier must adhere to rigorous standards to ensure the safety, effectiveness, and consistency of their products. The global demand for professional and at-home teeth whitening solutions continues to grow, and businesses need a reliable partner to produce top-quality syringes that meet customer expectations. In this blog, we will explore how a Safe Teeth Whitening Supplier ensures quality in Teeth Whitening Syringe OEM production, from sourcing ingredients to final packaging.

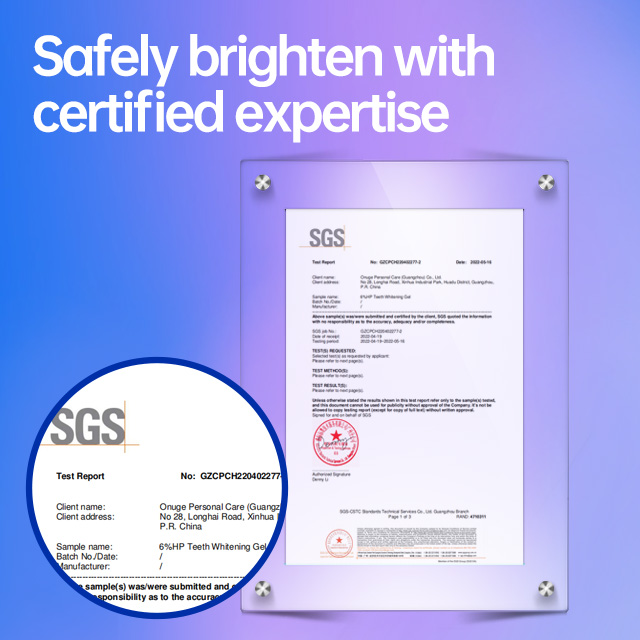

A Safe Teeth Whitening Supplier must comply with strict industry safety standards, such as those outlined by organizations like the FDA and ISO. These regulations govern everything from the ingredients used in the whitening gel to the design and functionality of the syringe. Suppliers must ensure that all products, including the syringes, meet specific quality certifications before they are distributed. By adhering to these safety standards, a supplier guarantees that the final product is safe for consumers, preventing adverse reactions and maintaining trust in the brand.

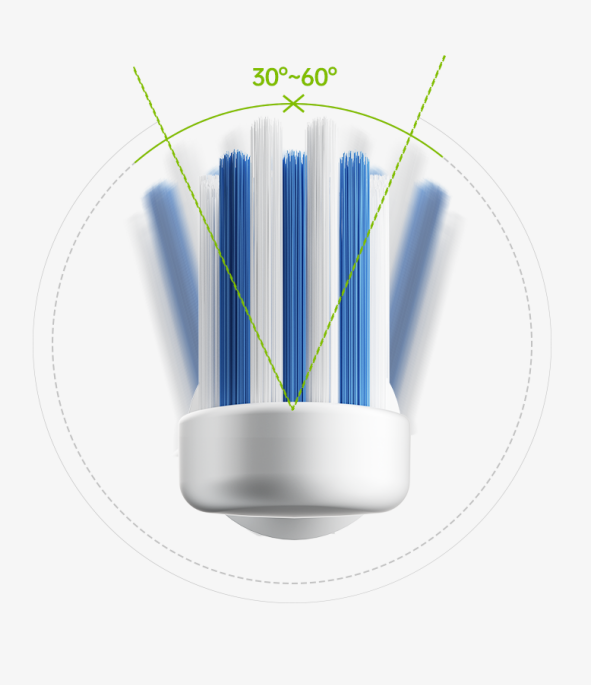

To ensure high-quality Teeth Whitening Syringe OEM production, a reputable supplier implements robust quality control measures throughout the manufacturing process. This includes inspecting raw materials, monitoring the production environment, and testing the finished syringes. Every step of the process is carefully tracked to ensure consistency and precision. Advanced manufacturing techniques, such as automated assembly lines and precise filling systems, can further enhance the quality of each syringe, ensuring uniform gel amounts and accurate application for each use.

The effectiveness of a teeth whitening syringe is largely determined by the quality of the whitening gel inside. A Safe Teeth Whitening Supplier ensures that the ingredients used in the gel are of the highest quality and sourced responsibly. High-quality hydrogen peroxide or carbamide peroxide is commonly used in the formulation, and it must be sourced from trusted suppliers. Additionally, the gel’s pH level must carefully controlled to prevent damage to the teeth or gums. By using premium ingredients, the supplier ensures a safe, effective whitening experience for customers.

A key benefit of partnering with a Safe Teeth Whitening Supplier is the ability to offer Teeth Whitening Syringe OEM production with customization options. This could involve custom formulations of whitening gels, unique syringe designs, or specific packaging solutions. Customization ensures that the syringes meet the unique needs of the brand and its customers. Whether it’s for a private label, a high-end spa, or a dental office, a supplier can offer tailored solutions to ensure that the product aligned with the client’s requirements and target market.

Sterility is a critical factor in the production of Teeth Whitening Syringe OEM products. A Safe Teeth Whitening Supplier ensures that the syringes manufactured and packaged in a clean, controlled environment to prevent contamination. This may involve sterilization techniques such as gamma irradiation or ethylene oxide treatment. The syringes must also carefully sealed and packaged in materials that maintain their safety. Packaging should be tamper-evident and designed to protect the product from environmental factors that could affect its performance.

A Safe Teeth Whitening Supplier conducts rigorous testing and batch sampling to verify the quality of the whitening syringes. This includes stability testing to ensure the whitening gel maintains its effectiveness over time. Batch sampling is critical for maintaining consistency across large orders, ensuring that each syringe performs to the same high standards. Suppliers who implement thorough testing at every stage of production reduce the risk of defects and customer complaints.

For Teeth Whitening Syringe OEM production, partnering with a Safe Teeth Whitening Supplier is essential to ensure the final product is of the highest quality. From adhering to regulatory standards and sourcing premium ingredients to ensuring precise manufacturing processes. By working with a supplier who prioritizes quality control, businesses can offer their customers safe, innovative. Contact us

.jpg)

Why Is Allergen Testing Critical for Post-Whitening Diets?

5 reasons for brands to enter the electric toothbrush industry in 2024

Oral Care Brand Expansion Guide

.jpg)

Waterproof Travel Electric Toothbrush OEM | Portable Oral Care

.jpg)

Rechargeable Toothbrush for Dental Hygiene Programs

What qualifications must a qualified teeth whitening product factory have?

Electric Toothbrush Screen Printing vs Pad Printing: The Best Choice for Complex Patterns and Gradient Colors

LED Light in Oral Care: Safety Insights for OEM Product Development

.jpg)

Long Battery Life Electric Toothbrush OEM Supplier

.jpg)

How Does Powsmart App Connectivity Turn Real-Time Brushing Data into Actionable Insights?

.jpg)

Rechargeable Adult Toothbrush Supplier for Global B2B Buyers

OEM Opportunities in Smart Features for Next-Gen Electric Toothbrushes

.jpg)

Pros and Cons: A Deep Dive into UVC and Ozone Sterilization Technologies

.jpg)

Need an Electric Toothbrush Packaging Supplier with Integrated Electric Toothbrush Logistics Services?

All You Want to Know About Teeth Whitening Gel

Several production equipment commonly used in electric toothbrush manufacturers