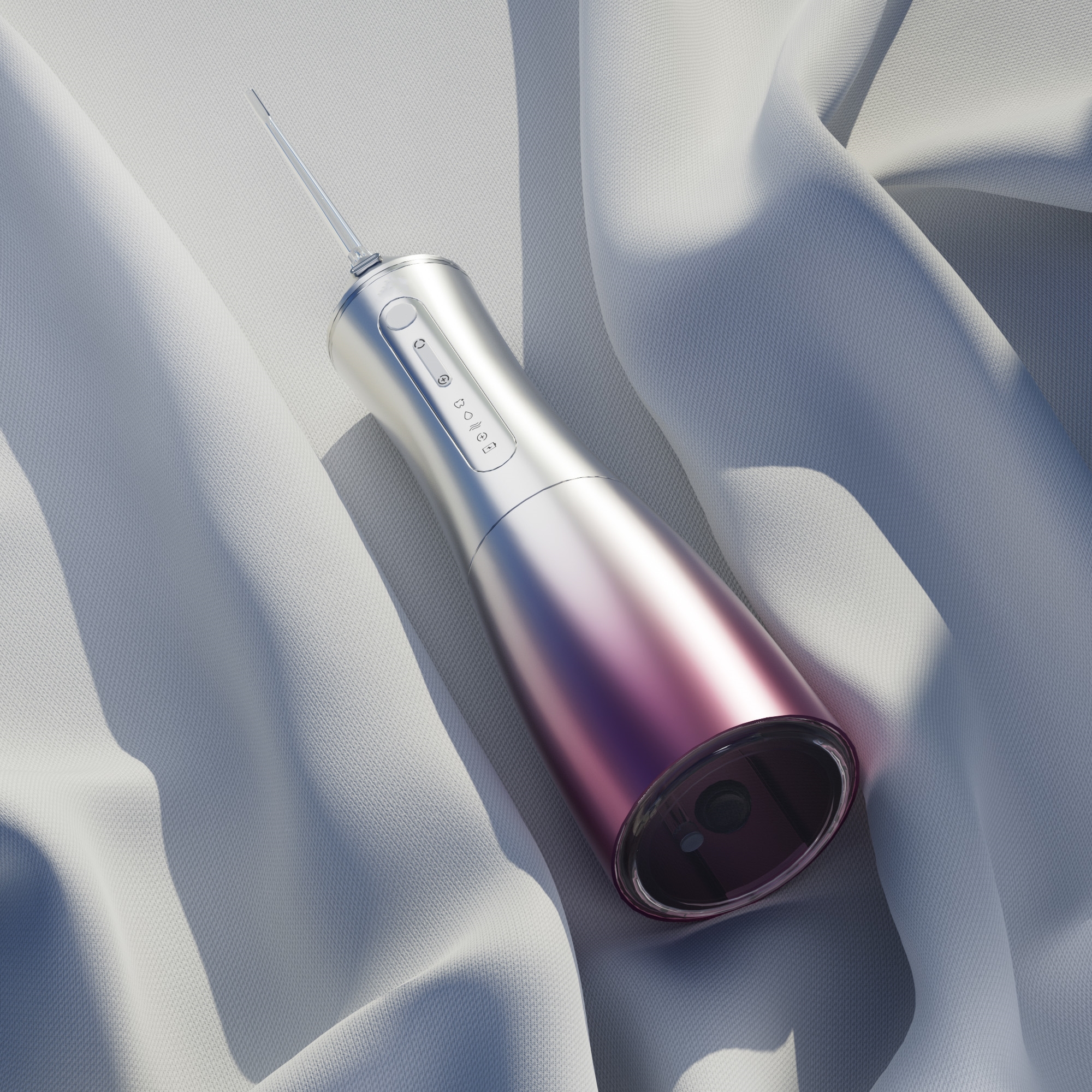

When it comes to Optimizing Water Flosser Performance, one of the most critical factors determining cleaning effectiveness is PSI—pounds per square inch, the unit that measures water pressure. A water flosser’s PSI level directly affects how efficiently it removes debris, plaque, and bacteria from between teeth and along the gumline. Too low, and cleaning power is insufficient; too high, and it may cause discomfort or gum irritation. Finding the right balance through PSI optimization is both a science and an engineering challenge for manufacturers.

PSI optimization involves more than just adjusting water pressure. Engineers must consider water flow rate, pulse frequency, and nozzle design to achieve consistent and effective performance. Clinical studies show that optimal cleaning typically occurs within a range of 40–90 PSI. Within this range, the pressure is strong enough to remove food particles yet gentle enough to protect delicate gum tissue. Manufacturers achieving this balance can ensure both cleaning power and user comfort, two key metrics for consumer satisfaction.

Behind every high-performing water flosser lies advanced pump technology. The pump determines how water pressure is generated, maintained, and modulated. Modern DC motor-driven pumps offer smoother flow and more precise PSI control compared to older AC models. In premium designs, variable-frequency pumps are used to allow dynamic PSI adjustment, giving users the flexibility to switch between gentle and deep-clean modes. As technology evolves, improvements in micro-pump efficiency and noise reduction have become essential in OEM product differentiation.

For private label and ODM clients, OEM engineering plays a decisive role in optimizing PSI settings to match brand positioning. For example, a brand targeting sensitive teeth users may request a soft-pressure model (40–60 PSI), while a professional oral care brand may prefer stronger pressure (70–100 PSI). OEM engineers collaborate closely with pump suppliers, nozzle designers, and testing teams to calibrate performance across multiple settings. This ensures each brand delivers a unique and consistent user experience that aligns with its target market.

Once the engineering parameters are set, manufacturers conduct repeated pressure calibration tests. Each water flosser undergoes performance verification to ensure that the water flosser performance remains stable under continuous operation. Laboratory-grade testing equipment simulates daily use to verify PSI stability, motor endurance, and waterproof integrity. This strict testing process helps reduce after-sales issues and enhances the long-term reputation of the OEM brand.

The science of Optimizing Water Flosser Performance reflects the perfect blend of physics, pump technology, and OEM engineering expertise. For water flosser manufacturers, mastering these parameters is key to achieving top-tier water flosser performance. Whether you’re developing a new model or refining an existing one, focusing on pressure balance, system stability, and engineering precision will ensure your brand stands out in the global oral care market.https://www.powsmart.com/product/water-flosser/

Why Is a Laboratory Test Report Indispensable for Marketing Claim Support?

.jpg)

Professional Dental Care Toothbrush Bulk

How to Maintain Good Oral Hygiene Without Irritation?

.jpg)

Understanding and Treating Gum Bleeding problem When Brushing

.jpg)

Advanced AI Electric Toothbrush Gift for Software Engineers Bangalore

Benefits of Travel-Sized Oral Care Products

What Makes a High-Quality Water Flosser? Material Choices for Durability and Performance

.jpg)

Why choose a budget electric toothbrush from a trusted brand?

Ensuring Safety in Personal Teeth-whitening: A Guide for OEM Brands

Electric Toothbrush Screen Printing vs Pad Printing: The Best Choice for Complex Patterns and Gradient Colors

Can a Whitening Booster Solution Be Promoted Through an App-connected Toothbrush Developer?

.jpg)

Cleaning Residue Plus Bristle Hardening – Double Trouble?

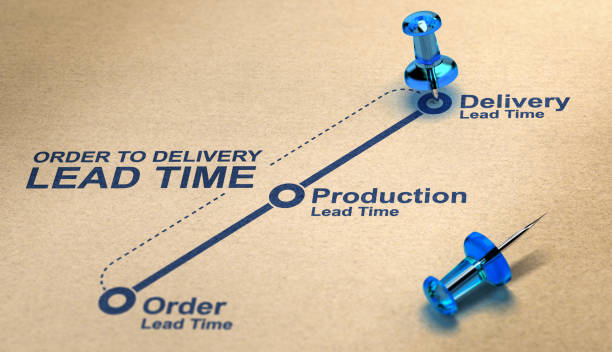

How to Optimize Electric Toothbrush Production Lead Time? Strategies for Shortening Lead Times and Enhancing Brand Competitiveness

Should a 7-Year-Old Use an Electric Toothbrush?

How does a sonic toothbrush work?

.jpg)

Does Your Flosser Last All Week?