The shell of an electric toothbrush not only affects its appearance and touch, but also greatly affects the durability, safety and cost of the product. Therefore, it is very important to choose the right material for the shell of an electric toothbrush. As the competition in the electric toothbrush market becomes increasingly fierce, many brands hope to make a fuss about the materials used in electric toothbrushes to enhance the competitiveness of their brands. This article will explore some common optional materials and their characteristics for the shell of an electric toothbrush, and analyze them in combination with relevant data.

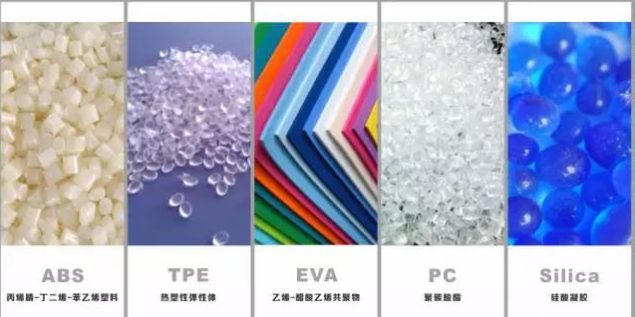

*ABS-has excellent mechanical properties with a balance of toughness, hardness and rigidity, suitable for making the internal bracket of the main body and the electric toothbrush handle shell.

*TPE-has a soft touch, which is suitable for coating and bonding with the ABS substrate, effectively enhancing the airtightness and elasticity of the button assembly part of the handle shell.

*EVA-has good cushioning, shock resistance, heat insulation, moisture resistance, chemical corrosion resistance, etc., and is non-toxic and non-absorbent. It is a high-quality material for making gaskets between components.

*PC-has high strength and elastic coefficient, high impact strength, wide operating temperature range, odorless and harmless to the human body, and meets the characteristics of sanitation and safety, making it one of the most ideal materials for brush head components and buttons.

*Silica-has high adsorption performance, good thermal stability, stable chemical properties, high mechanical strength, insoluble in water and any solvents, non-toxic and odorless, stable chemical properties, and can provide the most reliable waterproof parts.

As a material for electric toothbrush shells, stainless steel is popular because of its sturdy, durable and elegant appearance. Stainless steel shells can provide better antibacterial properties and service life. Although stainless steel is popular among the public, this type of material is limited by product design when applied, and is more suitable for short shell mold design.

Silicone shells are popular among young consumers because of their softness and comfort. This material not only feels good, but also provides good anti-slip properties. Electric toothbrushes with silicone shells are usually suitable for children or sensitive users. PTR-B2 is a perfect children electric toothbrush for customization. Although the production cost of silicone shells is higher than that of plastic, its market demand is gradually rising, especially in the market segment that pursues comfort and safety.

The choice of different shell materials directly affects the production cost and market pricing of electric toothbrushes. For example, the cost of plastic shells is relatively low, usually between US$2-5, while the cost of stainless steel shells may reach US$10-20. This cost difference requires brands to consider the target market and consumer preferences when positioning their products.

The shell design of electric toothbrushes should not only consider aesthetics, but also focus on functionality. A good shell design should be effectively waterproof and impact-resistant, and can reasonably layout the components. The feel of functional products is very important, and the grip should be in line with the ergonomic design of the human body. According to industry data, electric toothbrushes with reasonable shell design and comfortable product grip can increase user satisfaction by 15%. Therefore, when you’re choosing shell materials, you need to comprehensively consider the design and functionality. All of Powsmart’s design style are simple, classic and durable, and the grip is very comfortable for adults and children, and ergonomic design. https://www.powsmart.com/product/electric-toothbrush/

With the improvement of environmental awareness, many manufacturers and brand owners will begin to pay attention to the use of sustainable materials. For example, the research and development and application of bio-based plastics and recyclable materials will become an important trend in the selection of electric toothbrush shell materials in the future.

Sustainable plastics or materials come from renewable resources and are usually non-recyclable but biodegradable. Ordinary plastics are made from crude oil…it is a fossil fuel and will not regenerate. Sustainable plastics are made from corn, beans, sugarcane, vegetable oil, etc. Sustainable plastics are often called bioplastics. Another sustainable material is bamboo, which regenerates quickly and has tight fibers. Bamboo is antibacterial, sustainable and compostable, making it the best material for toothbrush handles.

In the future, we believe that consumer demand for environmentally friendly products will prompt more brands to adopt sustainable shell materials to meet market demand.

The material selection of electric toothbrush shells is crucial to the market performance of the product. Understanding the characteristics, cost differences and market trends of different materials can help brand owners make wise decisions in product development. As consumers pay more and more attention to quality and environmental protection, manufacturers should consider both performance and sustainability when selecting materials to promote innovation and progress in the electric toothbrush market.

Which Electric Toothbrush With Whitening Works Best?

Do Multi-Color Toothbrushes in a Bundle Savings Deal Prevent Sibling Fights?

Oral health facts & tips: Teeth whitening

.jpg)

Reasons for Water Flosser Leaking Problems: OEM Design Insights

.jpg)

Overpressure Cleaning Creates Interdental Stains? Double Crisis!

Quality Control Standards in Electric Toothbrush OEM Production

.jpg)

Cowboy Style Electric Toothbrush Texas

How Does Including a Wireless Charging Module Influence Kit Packaging Design?

.jpg)

Chicago holiday deals on a Chicago subscription toothbrush — worth it?

.jpg)

No-Mess Water Flosser Design: How Our Factory Solves Splashing for Your Brand

Why Bundle an Oral Care Kit with Cosmetic Whitening Equipment?

.jpg)

Water Flosser Innovations: Dual Molding & Color Consistency for Superior Performance

Quietest Electric Toothbrush OEM Models for NYC Apartments

Is Your Toothbrush Manufacturer Also a Toothbrush Wholesaler?

Why the Colorado outdoor toothbrush is the ultimate Colorado adventure toothbrush

.jpg)

Father’s Day Gift Electric Toothbrush for Texas Dad