In both home and medical settings, irrigators have become essential tools for improving hygiene and cleaning efficiency. However, when Nozzle Clogs and Water Leakage occur, they not only compromise performance but may also present safety risks. This leads manufacturers and users alike to ask: can an irrigator still be reliably used after such issues arise? In this blog, we explore the root causes, impacts, and solutions to these common problems.

To ensure optimal performance, an irrigator relies on smooth fluid flow and tight sealing. Nozzle Clogs typically occur when mineral buildup or debris blocks the spray outlet, resulting in inconsistent pressure. At the same time, Water Leakage often indicates a failure in the sealing system, which can lead to dripping or internal moisture damage. When these two issues occur together, the device’s cleaning ability is compromised, and its lifespan is shortened.

Common causes of nozzle blockages include:

Preventing nozzle clogs involves redesigning components for better flow, using anti-scale materials, and implementing regular maintenance protocols.

Water leakage typically stems from aging seals, poor material choices, or environmental wear. These leaks can lead to:

Improving sealing technologies and materials is critical to avoiding these long-term consequences.

In real-world applications, Nozzle Clogs and Water Leakage often go hand in hand:

Solving one problem without addressing the other may only offer a temporary fix. A system-level design approach is required.

To tackle these issues, B2B manufacturers can adopt a combination of reactive and preventive strategies:

This dual-track approach reduces downtime and enhances product longevity.

Looking ahead, manufacturers can explore innovations that reduce clogging and leakage:

Proactive improvement is key to standing out in a competitive, quality-driven B2B market.

Conclusion

The combination of Nozzle Clogs and Water Leakage can quickly degrade an irrigator’s performance, safety, and reliability. By understanding their causes and interplay, and implementing smart design and maintenance practices, manufacturers can offer durable, high-performance solutions. Innovation and long-term support remain the foundation for building customer trust and product competitiveness.

Interested in customized solutions or design upgrades? Contact us today to explore how we can support your manufacturing goals.

The Importance of Water Resistance for Teeth Whitening Devices and Anti-Saliva Corrosion Structure

What is the Electric Toothbrush Market Forecast?

Why Are Battery Recycling Challenges Ignored Despite Gum Massage Inconsistency?

Why Do Efficacy Comparisons Focus on Bleach Breakdown?

.jpg)

Is the Colorado mountain toothbrush really a Colorado durable toothbrush — proven?

.jpg)

Hawaii waterproof toothbrush vs. Hawaii beach toothbrush — which model makes sense for snorkeling trips?

How to Choose Good Bristles When Selecting an Electric Toothbrush?

Understanding and Treating Gum Bleeding problem When Brushing

Gentle Electric Toothbrush for Sensitive Aging Gums

ISO 13485 Certification Interpretation: How Do Electric Toothbrush Meet Medical Device-Grade Production Standards?

.jpg)

How to Choose a High-Profit Electric Toothbrush? A Must-Read Guide for Distributors

Luxury Gold Plated Electric Toothbrush Wedding Gift Surat

Improvement Record of Waterproof Defect of Water Flossers and the Latest Technical Solutions

Electric Toothbrush Manufacturing Process

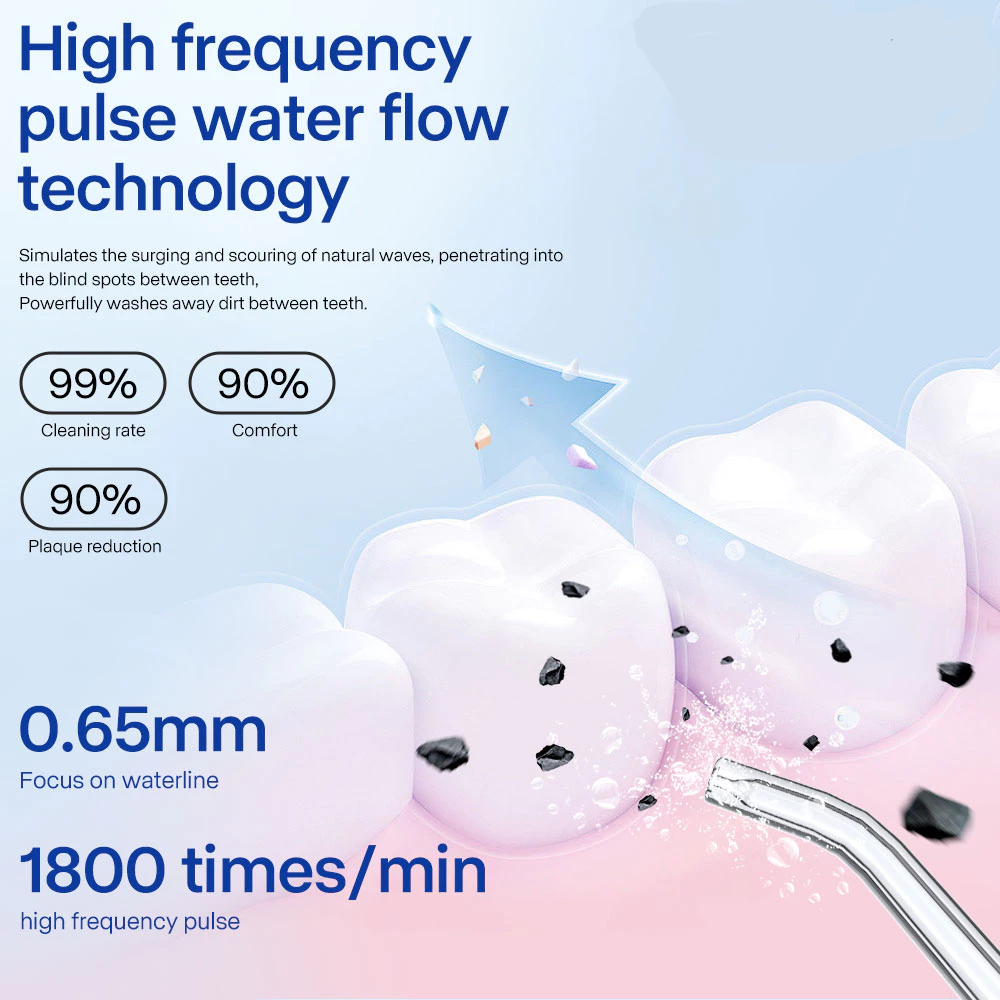

1200 vs 1800 water flosser pulse/Minute: Which Water Flosser Pressure Setting Works Best for Plaque Removal Without Gum Irritation?

Electric Toothbrush OEM Must-Know Question: How Much Money Can the Existing Mold Library Save?

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Deep Clean

electric toothbrush heads Regular Clean

electric toothbrush heads Ultra Soft

electric toothbrush heads Charcoal Infuse-Round

Customization Teeth Whitening Gel

Electric toothbrush heads Charcoal Infused-Diamond

Private Label Whitening Gel

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638