In the field of professional oral care devices, user safety incidents such as gingival burns combined with cervical hypersensitivity are emerging as an urgent concern, especially in the whitening and deep-cleaning product categories. Manufacturers may underestimate the combined impact of thermal, chemical, and mechanical stress on delicate gingival and cervical areas. But when burns and hypersensitivity appear together, they signal a systemic design or process flaw that must be addressed. How urgent is this issue—and how can product design prevent it?

Gingival burns refer to tissue damage along the gums, typically caused by:

Cervical hypersensitivity involves intense sensitivity in the tooth neck region (cementoenamel junction), often triggered by:

When these two issues occur simultaneously, user discomfort and potential oral injury escalate rapidly.

Experiencing gingival burns and cervical hypersensitivity together is not random:

Therefore, these two complaints often indicate a shared design flaw—typically excessive thermal output, poor gel formulation, or poorly shaped delivery heads. Company web:https://www.powsmart.com/product/electric-toothbrush/

Common risk factors contributing to combined injuries include:

Manufacturers must recognize that tissue safety depends on more than formulation or output specs—it requires full-system safety integration.

Effective design changes to prevent gingival burns and cervical hypersensitivity include:

Applying these design principles at R&D level can proactively eliminate root causes.

In mass production, manufacturers should implement:

These controls help detect risks that might otherwise bypass traditional mechanical testing.

By eliminating the combined risk of gingival burns and cervical hypersensitivity, manufacturers can:

In professional B2B sales, safety-focused certifications and test reports can differentiate products in competitive tenders or regulatory audits.

Yes, when gingival burns occur alongside cervical hypersensitivity, it signals an urgent systemic problem—one that requires immediate intervention at the design and QA levels. By understanding the link between thermal, chemical, and mechanical stresses, manufacturers can protect users more effectively and transform safety into a powerful market differentiator. Contact us

.jpg)

.jpg)

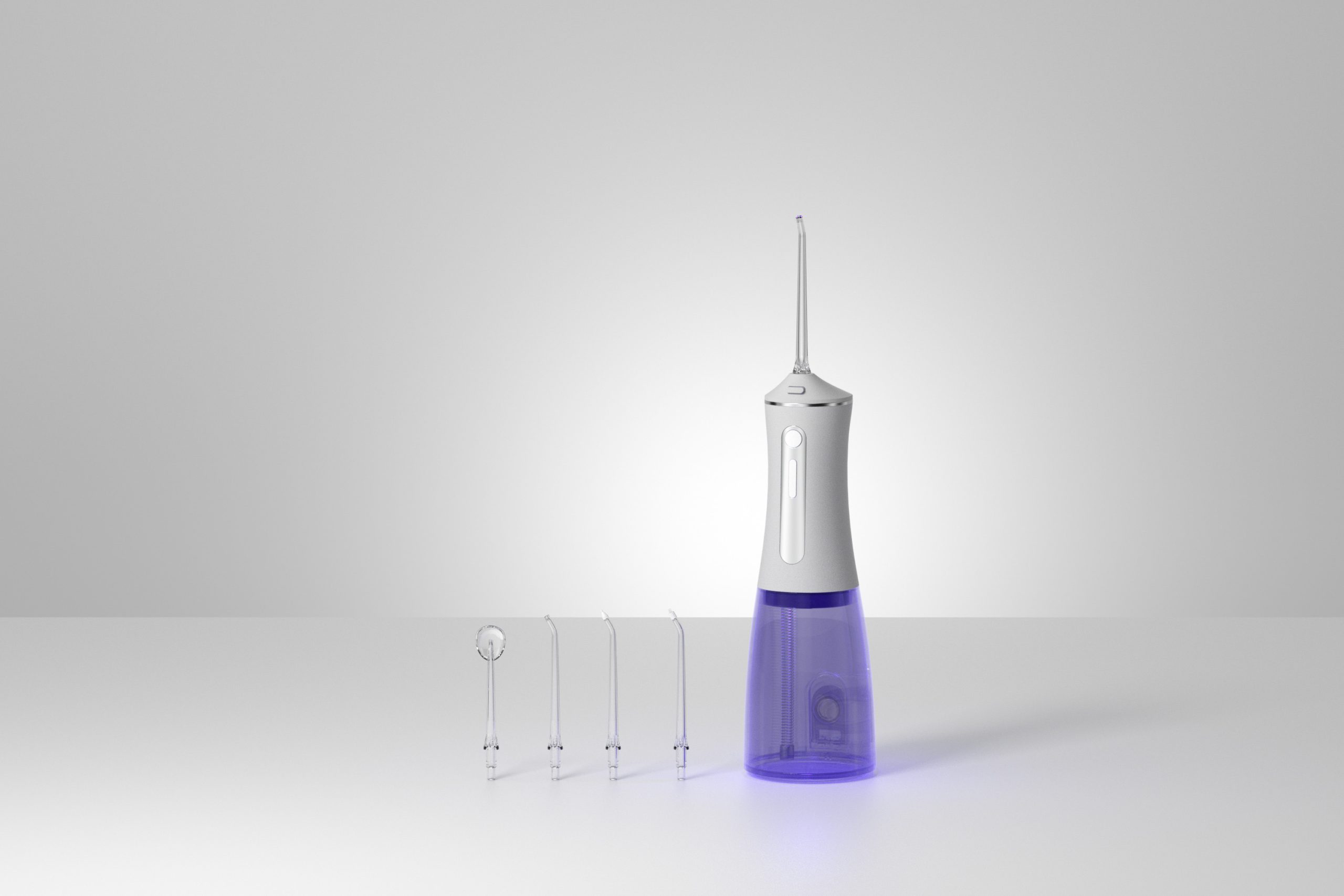

How to Create a High-Conversion Oral Irrigator Product Page

How to Check the Production Capacity of an Electric Toothbrush Factory?

Where to buy NYC eco toothbrush? Brooklyn toothbrush store locations!

How Do Travel Lock Jams Connect to Mode Switch Lag?

Sync Disruption with Tray Deformation – Tech Failure?

China Electric Toothbrush Factory Shipping Seattle Port | Reliable Supply

Best Dentist-Recommended Braces Cleaning Products for Braces Wearers

Is It Because Water Ingressed That the Water Flosser Can’t Be Charged?

PowSmart’s Commitment to Quality: What Sets Our Oral Care Products Apart

How to Optimize the Production Process of Electric Toothbrush? Intelligent Factory Upgrade Practice

Corporate Wellness Electric Toothbrush OEM: Employee Health Programs

Wireless Charging Electric Toothbrush Wholesale: Contact Technology Solutions

Do U-Shaped Toothbrushes Work?

How to Pick the Right Water Flosser for Your Oral Health: Answers from an Oral Irrigator Manufacturer

Seal Degradation Plus Battery Swelling – Safety Risk?

Best Toothbrush for Doctors | Clinical Oral Care

electric toothbrush heads Deep Clean

electric toothbrush heads Charcoal Infuse-Round

Electric toothbrush heads Charcoal Infused-Diamond

Private Label Whitening Gel

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Ultra Soft

electric toothbrush heads Regular Clean

Customization Teeth Whitening Gel