In today’s manufacturing industry, product durability and sustainability have become key competitive factors. Particularly in the brush head product sector, manufacturers often face the issue of Brush Head Frying—a phenomenon where prolonged usage and high-temperature processing lead to material degradation, fragility, or premature failure of the brush heads. At the same time, finding ways to reduce resource consumption and achieve environmental goals while enhancing product durability has become a focal challenge for the industry. This article explores the prospects of using a high Recycled Plastic Ratio to improve durability and sustainability from various angles, including technological breakthroughs, material optimization, and process innovation, while covering the following six key points.

Firstly, many manufacturers encounter the problem of Brush Head Frying during production. Over time, intensive use causes brush head materials to age, deform, and sometimes fracture. Experts in the industry believe that the durability of brush heads depends not only on the quality of the raw materials but also on the manufacturing process and product design. In this context, choosing more environmentally friendly materials and reducing production costs without compromising performance has become an urgent issue to resolve.

When addressing the aforementioned challenges, incorporating recycled plastics with a high Recycled Plastic Ratio offers a promising breakthrough for manufacturers. Using recycled plastics can not only reduce resource waste but also optimize the product structure, enhancing the brush head’s resistance to high temperatures and fatigue. Specifically, a high recycled plastic ratio can:

Secondly, to effectively prevent Brush Head Frying, manufacturers need to optimize both product design and manufacturing processes. Designers and engineers should consider the following:

High recycled plastic ratio advances technology and significantly enhances environmental sustainability. By significantly increasing the reuse rate of materials, enterprises can effectively reduce dependence on virgin plastics and lower carbon emissions and waste generation. Moreover, this strategy aligns with the rising environmental standards both nationally and internationally, providing strong support for companies in building a green brand image amidst fierce market competition.

In the current market environment, an increasing number of end users and partners are raising the bar for environmental attributes and durability in products. The use of a high Recycled Plastic Ratio meets this demand, showcasing significant advantages in product quality while opening new market opportunities for enterprises. By continually optimizing product design and manufacturing processes, companies can not only meet customer expectations but also enhance brand value, achieving a win-win situation for both economic and environmental benefits.

Looking ahead, the technology of a high recycled plastic ratio holds broad development prospects. With the continuous emergence of new materials and processes, the measures to combat Brush Head Frying will become more diversified and refined. Enterprises should keep abreast of international cutting-edge technologies, conduct regular product tests, and analyze data to continuously improve production processes, ensuring leading advantages in technology, quality, and environmental sustainability. Additionally, cross-industry collaboration and technological exchanges will further inject vitality into the overall industry upgrade.

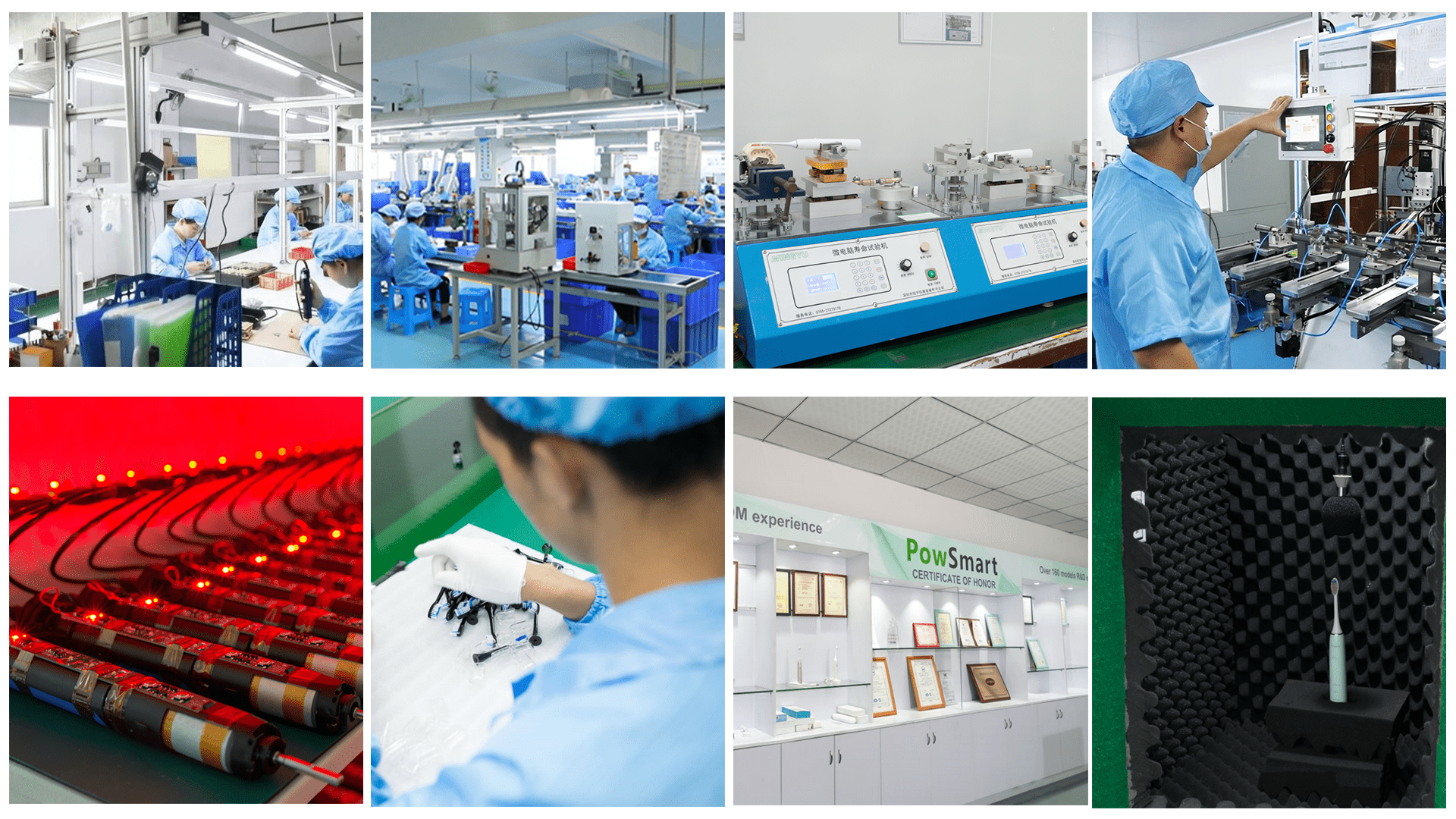

In summary, facing the Brush Head Frying issue in brush head products, increasing the Recycled Plastic Ratio can not only bring technological innovations but also provide a solid guarantee for enhanced durability and sustainability. Manufacturers who focus on production efficiency, product quality, and environmental sustainability will gain a significant competitive advantage in the future market. By continuously refining process workflows, optimizing material ratios, and strengthening design innovation, enterprises are poised to seize market opportunities and drive the entire industry to higher levels of development.https://www.powsmart.com/about-powsmart/

Future Trends of Electric Toothbrush Production: Intelligent, Environmentally Friendly, and Core Competitiveness Enhancement

How Houston pressure sensor tech elevates Houston deals toothbrush?

Charging Time Efficiency & Oral pH Alteration: A Subtle Link?

Chicago Electric Toothbrush Subscription Service

NY Dental Recommended Toothbrushes: Trusted Quality from Factory to You

Smart Home Health Devices: Connected Toothbrush OEM Solutions

Sonic toothbrush’s Efficiency | scale-up

Analysis of the Core Competitiveness of Electric Toothbrushes: How to Win the Market Through Technological Innovation?

ADA Accepted Electric Toothbrush OEM – Certification Support

Smart Toothbrush OEM Manufacturing for Tech Professionals

Electric Toothbrush for Hard Water Areas Arizona

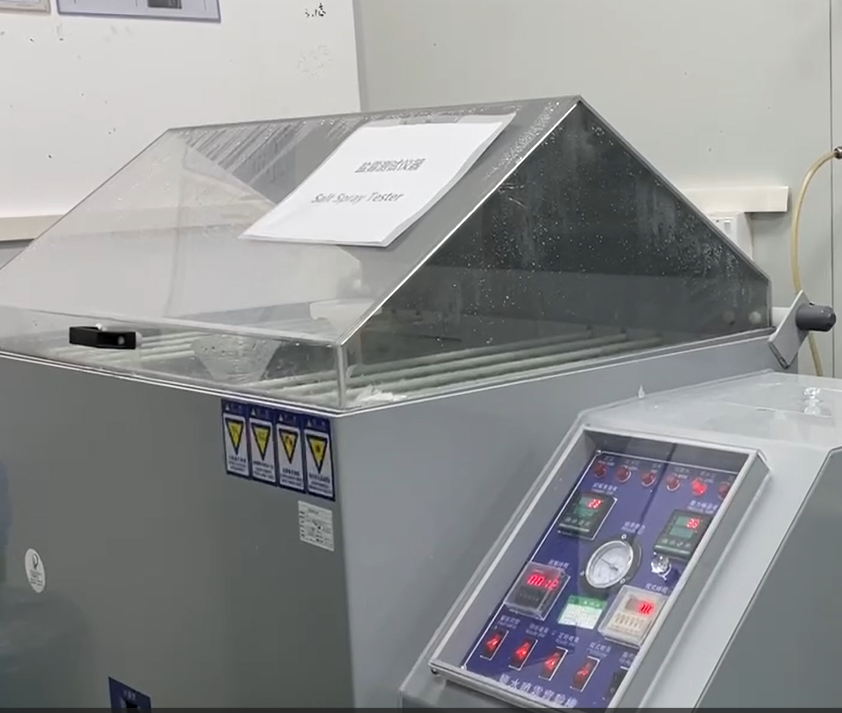

The Importance of Waterproof Rating for Electric Toothbrushes

Can Excessive Vibration from Electric Toothbrushes Loosen Teeth?

Why Is the Powsmart Ortho Head Key to the Clean Braces Technique?

Reducing Electric Toothbrush Auto power-On Failure Rates: Manufacturer’s 3-Fold Guarantee from Design to Assembly

Electric Toothbrush Motor Frequency and Cleanliness: How to Choose the Optimal Frequency?

Customization Teeth Whitening Gel

electric toothbrush heads Regular Clean

electric toothbrush heads Deep Clean

Electric toothbrush heads Charcoal Infused-Diamond

electric toothbrush heads Charcoal Infuse-Round

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Ultra Soft

Private Label Whitening Gel