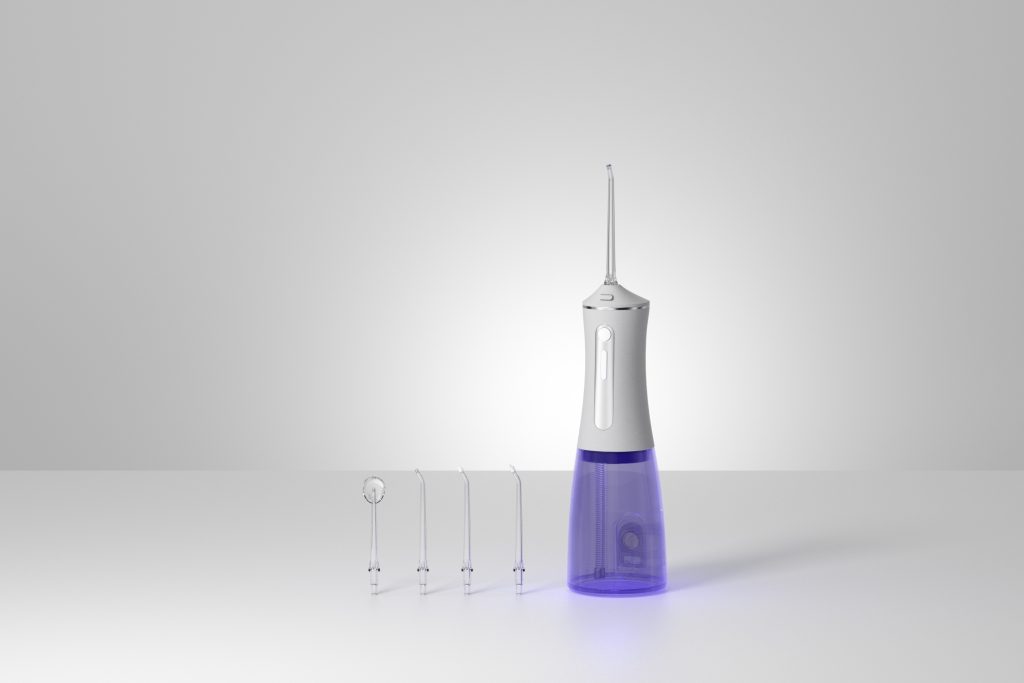

Mold errors in manufacturing can lead to costly defects, production delays, and a compromised product experience. For water flosser manufacturers, ensuring Flosser Anti-Misoperation features and implementing a robust Mold Maintenance strategy are crucial steps toward achieving high product quality and production efficiency. This blog explores how these two factors can help overcome mold-related challenges and ensure smooth manufacturing operations.

Mold errors occur due to various factors, including wear and tear, improper handling, and inadequate maintenance. These errors can result in defects such as warpage, dimensional inconsistencies, or surface imperfections, all of which negatively impact the Flosser Anti-Misoperation mechanisms. A poorly molded component may fail to fit correctly, leading to assembly failures or operational malfunctions in the final product. Understanding these challenges is the first step toward implementing effective solutions.

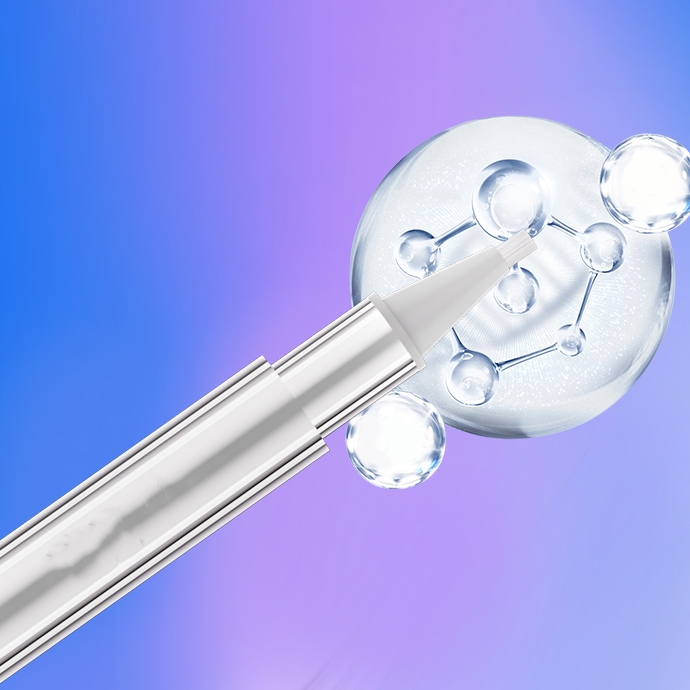

A well-designed Flosser Anti-Misoperation system ensures that components fit and function correctly, minimizing user errors and operational failures. If the mold produces defective parts, the anti-misoperation mechanism may fail to align properly, leading to performance issues in the flosser. By integrating smart design solutions, such as precise locking mechanisms and sensor-based detection, manufacturers can mitigate these risks. However, achieving consistent anti-misoperation functionality requires maintaining mold accuracy and preventing defects before they occur.

Effective Mold Maintenance is essential for preventing production disruptions and ensuring product consistency. Regular cleaning, lubrication, and inspection of molds can significantly reduce wear and prolong their lifespan. Advanced maintenance strategies include:

By prioritizing mold maintenance, manufacturers can reduce production defects and ensure that Flosser Anti-Misoperation features function reliably.

To further improve mold performance and longevity, many manufacturers are adopting high-durability materials and coatings. These enhancements help minimize deformation, reduce adhesion of plastic residues, and maintain the fine details required for Flosser Anti-Misoperation mechanisms. High-performance coatings also prevent corrosion, ensuring molds remain in optimal condition for longer periods, thereby reducing operational costs and improving efficiency.

Smart manufacturing technology plays a crucial role in ensuring mold reliability. By incorporating real-time monitoring and predictive maintenance tools, manufacturers can address potential mold issues before they lead to defects. Data-driven analysis can help track patterns of wear and adjust production settings to optimize both Mold Maintenance and Flosser Anti-Misoperation efficiency. These innovations help manufacturers maintain high precision and reduce overall defect rates.

Looking ahead, advancements in mold design, material engineering, and automated maintenance will further enhance water flosser manufacturing. Manufacturers that adopt proactive Mold Maintenance strategies and refine their Flosser Anti-Misoperation features will achieve greater product consistency, reduced waste, and improved consumer satisfaction. Investing in these technologies today ensures a competitive edge in the evolving oral care market.

Mold errors can significantly impact production efficiency and product quality, but by implementing Flosser Anti-Misoperation solutions and prioritizing Mold Maintenance, manufacturers can mitigate these risks. A proactive approach to mold care, combined with advanced materials and smart monitoring, ensures high-precision production, reduced downtime, and superior product reliability. By embracing these strategies, manufacturers can achieve smoother operations and maintain a strong position in the competitive water flosser market.https://www.powsmart.com/about-powsmart/

Cheap vs High-End Electric Toothbrushes : 5 Key Differences You Should Know

Electric Toothbrush Precision Mold Shell: How to Achieve Durability and Beautiful Design?

How does Pulse Water Technology benefit from the programmability of a Multi-pressure Chip?

.jpg)

Hose Kinking Leading to Weak Suction—A Hidden Efficiency Killer?

.jpg)

Is the tongue cleaner on the back of the toothbrush useful?

.jpg)

Ultimate Guide to Whitening Electric Toothbrushes for Beginners

How to Choose the Right Oral Care Product: A Comparison Between Electric Toothbrushes and Oral Irrigators

Does the Nozzle of the Water Flosser Need to Be Changed Regularly?

College Student-Friendly Electric Toothbrush Features – Budget OEM Designs

.jpg)

Weak Vibration Plus Sensor Failure – Double Malfunction?

.jpg)

Can a Toothbrush Design Company Help Create a Toothbrush for Sensitive Teeth?

How to Ensure That Electronic Oral Care Devices Have Good Waterproof Performance

Is a Travel Electric Toothbrush Best for Orlando?

.jpg)

Electric Toothbrush for Elderly Care Facilities – Gentle, Efficient, and Hygienic Oral Care for Seniors

Is It Bad to Use a Dental Water Flosser Every Day?

.jpg)

Los Angeles sonic toothbrush wholesale distributor