In today’s fast-paced manufacturing environment, achieving high-quality finishes and vibrant aesthetics is essential to stay competitive. Innovative processes like Electrostatic Spray Coating and Multi-Color Dual Molding are at the forefront of this evolution, offering Powsmart technology co., ltd advanced solutions that enhance both product performance and visual appeal. In this blog, we explore six critical aspects of these technologies and how they are reshaping the industry.

Modern production demands smarter, more efficient processes. Electrostatic Spray Coating is an innovative technique that utilizes electrically charged paint particles to achieve a uniform and durable finish. This method minimizes overspray, reduces waste, and ensures that every brush receives an even, high-quality coating. Manufacturers are increasingly adopting this technology as it not only elevates product quality but also supports environmentally responsible practices.

Parallel to coating advancements, Multi-Color Dual Molding is transforming how products are designed and produced. By integrating two distinct color systems within a single molding cycle, this process allows for seamless color transitions and intricate designs without additional assembly. This technique not only enhances the aesthetic appeal of smart brushes but also improves functional performance by reducing the need for secondary processing steps.

Combining Electrostatic Spray Coating with Multi-Color Dual Molding creates a synergistic effect. For instance, after a dual molding process creates a sophisticated, multi-hued base, an electrostatic spray coating can be applied to further enhance surface durability and resistance to wear. This integrated approach results in a product that is not only visually striking but also engineered for long-lasting performance, making it a preferred choice for manufacturers targeting both quality and efficiency.

Efficiency remains a top priority in manufacturing. With Electrostatic Spray Coating, the precise application of coatings translates into less material waste and lower energy consumption. Similarly, Multi-Color Dual Molding streamlines production by eliminating the need for post-molding color additions. Together, these processes reduce production cycles and minimize operational costs, enabling manufacturers to meet high-volume demands without compromising on quality.

Robust quality control is essential to ensure that every product meets strict performance and aesthetic standards. The controlled environment of Electrostatic Spray Coating allows for consistent quality with minimal human error, while Multi-Color Dual Molding ensures precise color integration and dimensional accuracy. Additionally, these techniques promote sustainability by reducing waste and improving resource efficiency, which is increasingly important in today’s eco-conscious market.

Looking ahead, advancements in digital control systems and material sciences are poised to further refine Electrostatic Spray Coating and Multi-Color Dual Molding processes. Future innovations may include real-time monitoring of coating thickness and automated adjustments during the molding cycle, ensuring even greater consistency and efficiency. Manufacturers who invest in these cutting-edge technologies will not only meet evolving market demands but also set new benchmarks in product quality and sustainability.

In conclusion, integrating Electrostatic Spray Coating with Multi-Color Dual Molding represents a significant leap forward in smart brush production. By embracing these advanced techniques, manufacturers can achieve superior aesthetics, improved durability, and enhanced efficiency—all while supporting a sustainable production model. This holistic approach to product development ensures that companies remain competitive in a rapidly changing market.https://www.powsmart.com/about-powsmart/

Are multiple cleaning modes worth it for a custom clean?

A Comprehensive Guide to Teeth Whitening Gel Ingredients

Budget electric brush OEM Manufacturers in Los Angeles

.jpg)

Brush + Flosser Combo Electric Toothbrush Wholesale | 2-in-1 Oral Care

.jpg)

Professional Whitening Device for Spas

Should You Get Your Child a Water Flosser?

Dental Care Products Market – Is There Space for Startups?

Can CE Marking Validate Your Product’s Whitening Effect Claim?

Finding the Right Kids’ Toothbrush: An OEM Guide to U-Shaped vs. Sonic Options

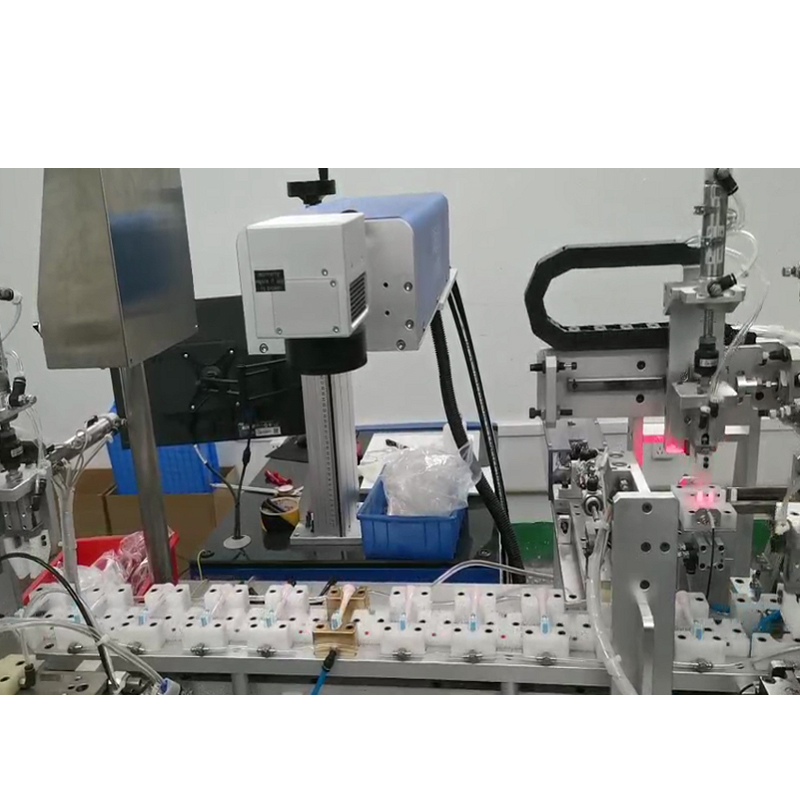

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?

.jpg)

How does the UV sterilization function provide you with a sterile and clean brush head every time you brush?

.jpg)

Whitening & Polishing Electric Toothbrush – OEM/ODM Services

.jpg)

Will You Get a Transparent Toothbrush Cost Breakdown?

Does Your Electric Toothbrush Factory Hold Stringent Quality Control Certification?

.jpg)

Brush + Flosser Combo Electric Toothbrush Wholesale

Does Black Electric Toothbrush ODM Face Handle Corrosion?