As the demand for advanced oral care solutions grows, manufacturers are focusing on innovations that enhance hygiene, durability, and performance. Two key advancements in electronic toothbrush production are antimicrobial bristles and precision brush head molding, which significantly improve user experience and product longevity. This blog explores how these technologies optimize manufacturing and elevate oral care standards.

Oral hygiene depends not only on effective brushing but also on keeping the toothbrush itself clean. Traditional toothbrushes can harbor bacteria, leading to potential oral health issues. By incorporating antimicrobial bristles, electronic toothbrushes offer:

Antimicrobial bristles provide a higher level of cleanliness, making electronic toothbrushes a superior choice for health-conscious consumers.

The effectiveness of an electronic toothbrush depends on the quality and precision of the brush head. Brush head molding technology ensures:

By using high-precision injection molding techniques, manufacturers achieve consistent quality, enhancing both brushing efficiency and user comfort.

To produce high-quality electronic toothbrush brush heads, manufacturers use advanced materials that optimize both hygiene and performance:

Selecting the right materials contributes to the durability, safety, and efficiency of the final product.

Integrating antimicrobial bristles into large-scale production requires cutting-edge technology and strict quality control. Key production advancements include:

These innovations allow manufacturers to consistently produce high-quality antimicrobial toothbrush heads at scale.

Leading electronic toothbrush manufacturers offer OEM/ODM customization to meet the branding and design requirements of global partners. Customization options include:

By providing flexible production solutions, manufacturers help brands stand out in the competitive oral care market.

At Powsmart technology co, ltd, we specialize in high-quality electronic toothbrush manufacturing, incorporating antimicrobial bristles and precision brush head molding for superior performance. Our advantages include:

1、State-of-the-Art Manufacturing Facilities – Ensuring precision and consistency.

2、ISO & CE-Certified Production – Guaranteeing compliance with global standards.

3、Eco-Friendly & Sustainable Materials – Supporting environmental responsibility.

4、End-to-End OEM/ODM Services – From concept to final product delivery.

Looking for a trusted manufacturing partner for your electronic toothbrush brand? Contact us today to explore innovative solutions that enhance oral care and hygiene.

.jpg)

Sonic Toothbrush Factory for Brands | OEM & Private Label Production

.jpg)

Top Health Gadgets for New Year 2024 | Powsmart

Can Scalable Toothbrush Production Capacity Optimize Your Toothbrush Material Sourcing Costs?

How Does a Smart Toothbrush with App Integrate into Broader Oral Care IoT Solutions?

.jpg)

Wholesale Smart Electric Toothbrush Factory | Bulk Supply Solutions

.jpg)

Gentle Electric Toothbrush for Sensitive Aging Gums

Why Does My Electric Toothbrush Keep Turning Itself On?

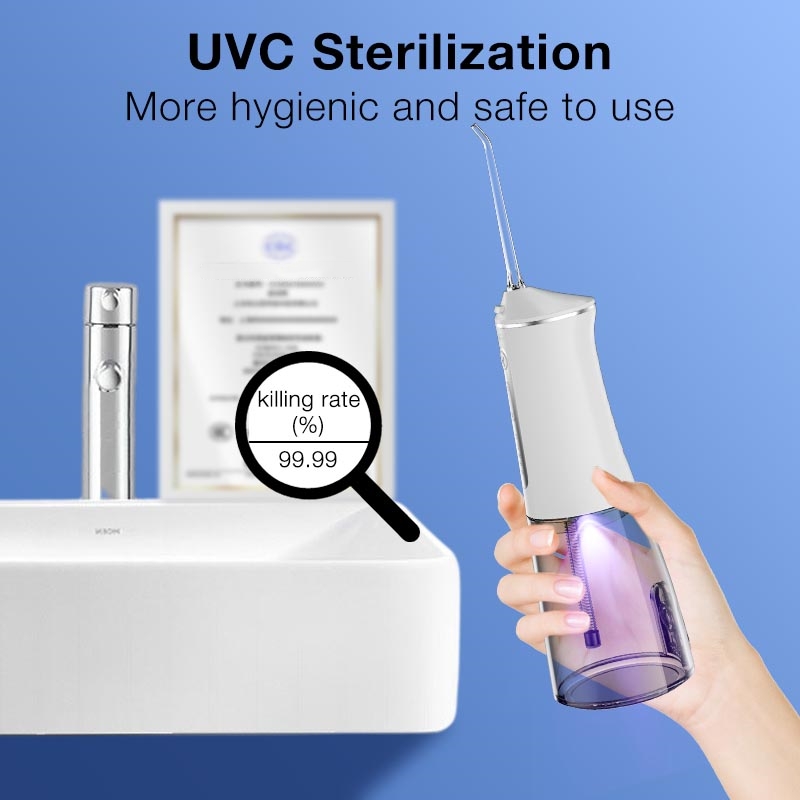

Oral Irrigators That Can Replace Dental Floss Are So Useful! 5 Common Misunderstandings About Using Them

Five benefits of using a Wave electric toothbrush

.jpg)

Water Flosser Energy Saving & Batch Tracking: Enhancing Efficiency and Quality Control

.jpg)

Is a whitening toothbrush the key to a Texas bright smile?

.jpg)

Sustainable Electric Toothbrush Wholesale

Electric Toothbrush Charging Dock OEM: Stylish and Functional Accessories

OEM Strategies to Prevent Water Flosser Mold and Ensure User Health

How Does UV Whitening Technology Comply with Dental Grade Whitening Standards?

.jpg)

Inside an Electric Toothbrush: Understanding Battery Types for Smart OEM Sourcing