As the demand for smart and stylish oral care products rises, manufacturers of electric toothbrushes face a dual challenge: how to ensure long-term durability while also delivering a visually appealing design. At the heart of this lies the quality of the electric toothbrush precision mold shell, the choice of materials, and the strength of design-engineering collaboration. This article outlines the six key strategies manufacturers use to create electric toothbrush shells that are both durable and attractive, naturally incorporating the keywords “Electric toothbrush mold”, “shell customization”, “ABS/PP material”, and “industrial design support”.

The first step in producing a high-quality toothbrush precision mold shell is developing a high-precision electric toothbrush mold. A well-designed mold ensures:

Consistent dimensions and tight tolerances

Seamless fit with internal components

A smooth, refined surface ready for finishing touches

By investing in precision mold technology, manufacturers lay the groundwork for both durability and visual appeal right from the tooling stage.

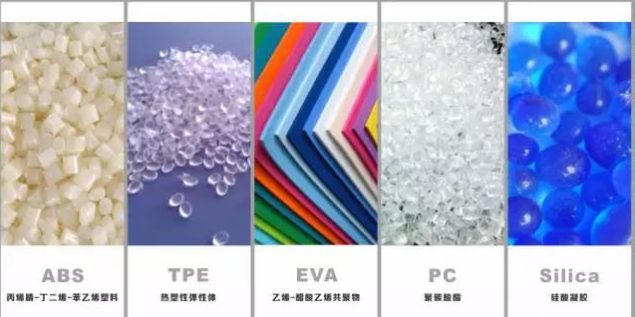

Choosing the right materials is critical for performance. The most common choices for toothbrush shells are ABS (Acrylonitrile Butadiene Styrene) and PP (Polypropylene):

ABS material: Offers high impact resistance, excellent dimensional stability, and a premium finish. Ideal for achieving sleek, glossy aesthetics with lasting strength.

PP material: Known for its flexibility, chemical resistance, and lightweight nature. Ideal for cost-effective production without compromising basic durability.

By selecting the right ABS/PP material based on target market and product positioning, manufacturers can strike a perfect balance between function and form.

Modern consumers expect more than just functionality—they expect personalization. That’s where shell customization comes in:

Custom color schemes and finishes (matte, gloss, metallic)

Laser-etched logos or printed branding

Textured grips for ergonomic feel and added style

Flexible shell customization not only meets brand requirements but also elevates the perceived value of the product in the eyes of end users.

A great toothbrush shell isn’t just about materials or tooling—it’s about smart design. With strong industrial design support, manufacturers can:

Optimize internal layout to protect electronic components

Enhance grip and user ergonomics without sacrificing design

Coordinate colors, curves, and surface treatments to align with modern trends

Collaboration between designers and engineers ensures that products are both beautiful and practical—no compromises.

To validate durability claims, manufacturers must implement strict quality control and mechanical testing protocols:

Drop tests for impact resistance

Temperature cycling for material stability

Water ingress protection (IPX ratings) to ensure safety and longevity

Such testing ensures the electric toothbrush shell can withstand daily wear and tear, keeping the product both functional and aesthetically intact over time.

Whether you’re scaling up production for retail or OEM orders, consistency is key. With optimized mold design and controlled injection parameters, manufacturers can produce thousands of units with:

Identical surface finish and coloration

Precise assembly fit

Minimal rework or defects

Scalable production combined with design precision ensures the end result is a durable, stylish product ready for the competitive global market.

The perfect electric toothbrush precision mold shell is no accident—it’s the result of intentional choices at every stage of development. By focusing on:

Precision electric toothbrush precision mold shell creation

Smart ABS/PP material use

Flexible shell customization

Strong industrial design support

Rigorous durability testing

…manufacturers can consistently deliver electric toothbrushes that are both resilient and visually stunning.

Looking for a trusted partner for your next electric toothbrush project? We offer full-process support, from mold design to mass production, tailored to your brand’s needs.

�� Contact us for a quote or design consultation today.https://www.powsmart.com/

.jpg)

Why is OEM Water Flosser Design Critical for Partnering with a Water Flosser Filter Supplier?

Where to Find Orlando Deals Toothbrush for Orlando Travel Toothbrush?

Advantages of Wireless Teeth Whitening Devices

Can a Travel-friendly Design Be Incorporated into a Luxury Gift Set?

.jpg)

Cordless Water Flosser Wholesale – Global B2B Supply for Retailers & Brands

.jpg)

Seattle Eco-Conscious Electric Toothbrush

Understanding and Treating Gum Bleeding When Brushing

How Does Blue LED Technology in Whitening Ensure Gum Protection?

.jpg)

Incomplete Flushing after Flow Interruption?

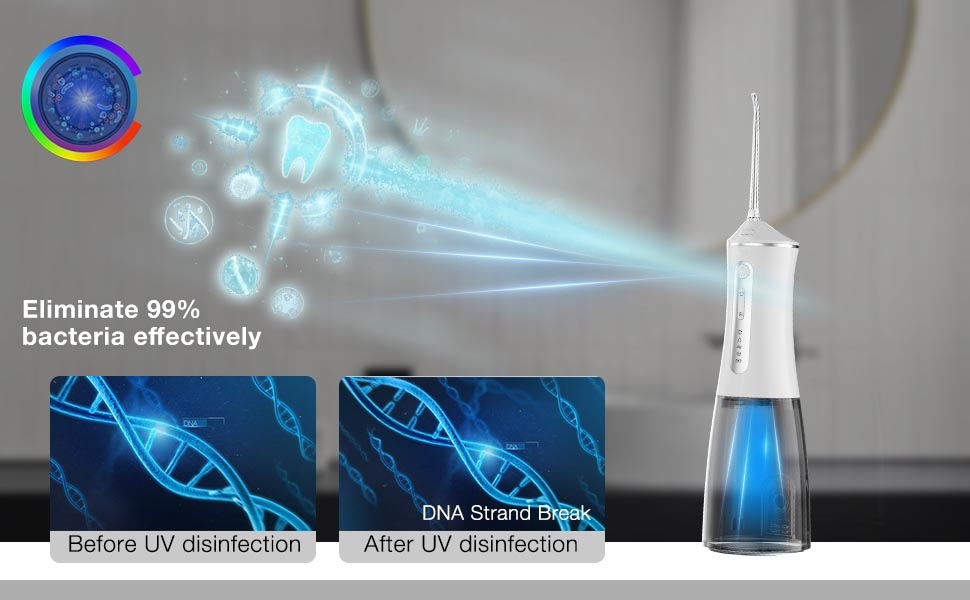

The Future of Toothbrush Sterilization: OEM Integration of UV and Antibacterial Tech

.jpg)

Tray Discomfort Triggering Mouth Ulcers – Coincidence?

.jpg)

Oral Ulcers Fluorosis aggravation? Whitening Device Contraindications!

The Sterilizing Function of the Dental Flosser You’d Love to Know

.jpg)

Best Electric Toothbrush for Sensitive Gums – Gentle and Effective Oral Care

.jpg)

Are Waterproof Electric Toothbrushes Popular in Miami?

.jpg)

Alaska Electric Toothbrush for Travel