Electric toothbrush housing material OEM development plays a critical role in product durability, user comfort, and long-term reliability. Housing materials must protect internal components while maintaining ergonomic appeal.

The housing serves as both structural protection and a user interface. Therefore, material selection directly affects impact resistance, waterproof performance, and surface finish.

Moreover, housing materials influence perceived product quality, especially in mid-to-high-end market segments.

ABS and PC materials are widely used due to their balance of strength and moldability. For premium products, PC+ABS blends provide improved impact resistance.

Additionally, soft-touch coatings or TPE inserts are applied to enhance grip and comfort. These materials must remain stable under moisture and repeated handling.

OEM housing material configurations can be reviewed here:

👉 https://www.powsmart.com/custom-oral-care/

Material performance depends heavily on mold design. Wall thickness uniformity and internal rib structures improve strength without increasing weight.

Furthermore, ultrasonic welding or adhesive bonding techniques are selected based on material compatibility to ensure waterproof sealing.

According to manufacturing standards, material stability under temperature variation is essential for consumer electronics.

External reference: https://www.iso.org/

Housing materials undergo drop tests, stress tests, and moisture exposure cycles. These tests verify that materials maintain integrity during daily use.

In addition, surface wear testing ensures coatings do not degrade prematurely, protecting brand appearance.

OEM partners assist brands in selecting materials aligned with target positioning. Matte finishes, glossy surfaces, or eco-oriented materials support different branding strategies.

A professional electric toothbrush housing material OEM enables brands to balance aesthetics, durability, and production efficiency.

Top 10 California electric toothbrush factory for OEM/ODM Services

What are the Basic Procedures for Customizing Teeth Whitening Kits?

Are Eco-Conscious Electric Toothbrushes in Demand in Seattle?

.jpg)

Recyclable Packaging Toothbrush Supplier | Eco-Friendly Oral Care

.jpg)

Fast-Charge Electric Toothbrush OEM | Rapid Charging & Global Standards

.jpg)

High Torque Sonic Toothbrush OEM for Professional Oral Care Brands

.jpg)

Designing Kid Electric Toothbrush Models for Your Fun Dental Care Products Range?

.jpg)

Does POWSMART Kids Electric Toothbrush Contain Material Toxicity?

Why Add a UV Sanitizing Component When Oral Care Kit Bundling for Travel?

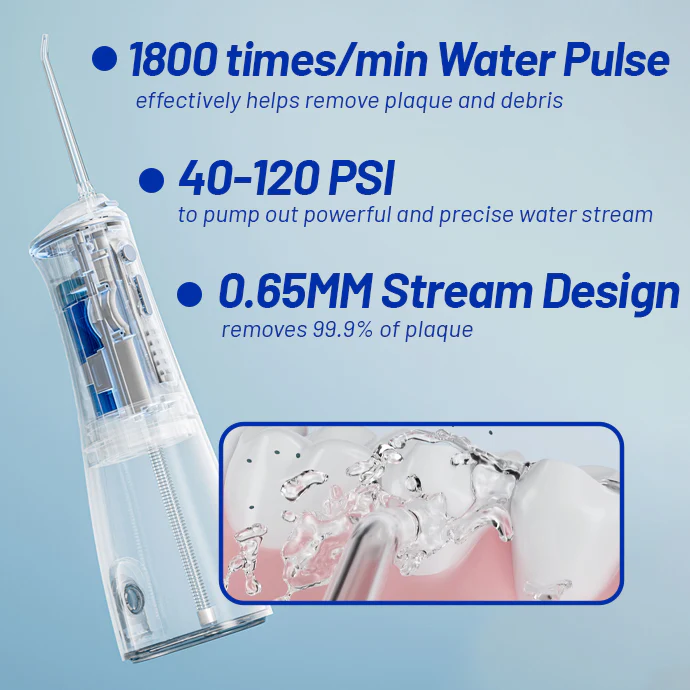

How to Choose the Most Suitable Nozzle of the Oral Irrigator?

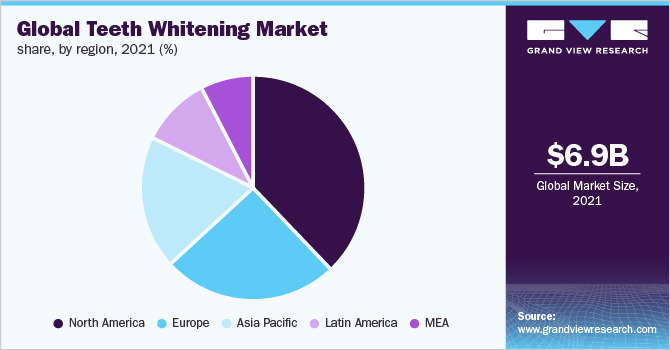

Analysis of Differences in Preferences for Teeth Whitening Devices in the European and American Markets vs. Asian Markets

Electric toothbrush: the new choice for professional oral care

.jpg)

Is the tongue cleaner on the back of the toothbrush useful?

Mitigating LED Teeth Whitening Side Effects Through OEM Design & Formulation

Why is an LED Whitening Lamp Critical for Activating an Accelerated Whitening Solution?

.jpg)

Whitening Pen + LED Kit Supplier | Teeth Whitening Combo OEM