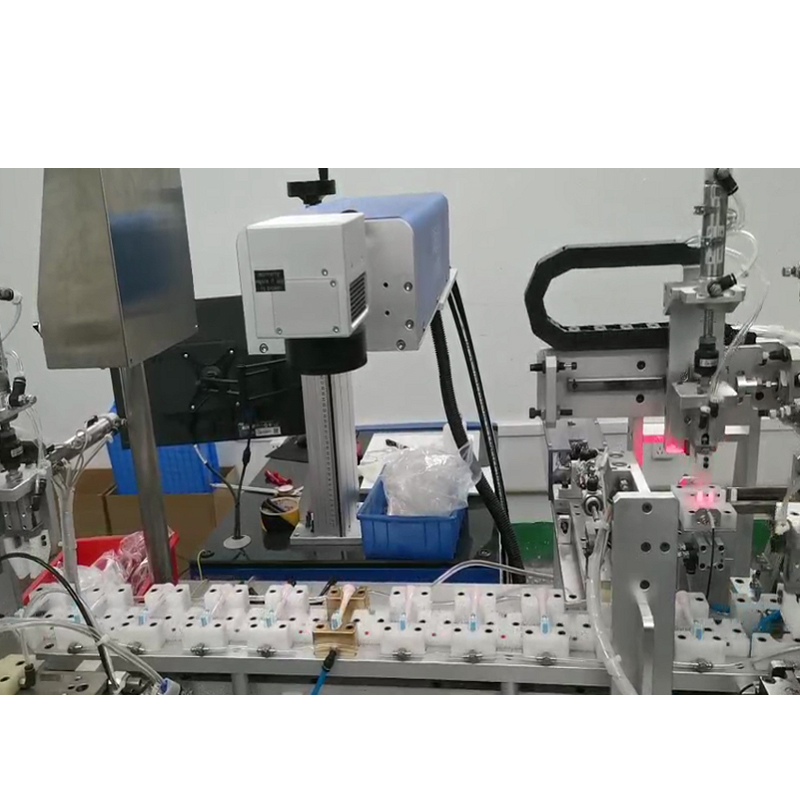

In oral irrigation and fluid-delivery devices, system accuracy depends on more than just the nozzle itself. The precision of Water Tank Molding directly influences pressure stability, flow consistency, and ultimately the performance of Precision Nozzle Manufacturing. For B2B manufacturers and OEM partners, understanding this relationship is essential to achieving reliable and repeatable production outcomes.

Precise Water Tank Molding ensures consistent internal volumes and outlet alignment. These factors directly affect inlet pressure conditions, which Precision Nozzle Manufacturing relies on to deliver stable and predictable spray patterns.

The connection point between the water tank and nozzle assembly must meet tight tolerances. Variations in Water Tank Molding can lead to misalignment or leakage, reducing the effective output of precision-manufactured nozzles.

Uniform wall thickness and accurate geometry achieved through controlled Water Tank support stable pressure during operation. This stability allows Precision Nozzle Manufacturing processes to maintain consistent jet performance across repeated use cycles.

Inaccurate molding can introduce stress during assembly, affecting downstream components. High-precision Water Tank minimizes deformation, protecting the integrity of precision nozzles and reducing performance variation.

When Water Tank Molding precision is consistent, fewer compensations are required during nozzle assembly. This alignment improves overall Precision Nozzle Manufacturing yield and simplifies quality inspection processes.

For large-scale production, small deviations can compound into major performance issues. Precision-controlled Water Tank Molding enables scalable Precision Nozzle Manufacturing with consistent output across batches and production lines.

Precision in fluid-delivery systems is achieved at the system level, not in isolation. By ensuring high-accuracy Water Tank, manufacturers can support reliable Precision Nozzle Manufacturing output, improve production efficiency, and deliver consistent performance for OEM and global brand partners. Contact us

.jpg)

How Can Gradient Color Injection Molding Technology Improve the Attractiveness of Electric Toothbrushes?

.jpg)

ADA Compliant Electric Toothbrush Supplier

All-in-One Family Toothbrush Solution

.jpg)

Dental Gifts Mobile AL Supplier | Corporate & Patient Gifting

.jpg)

Hose Rupture and Gum Discomfort – Related?

Why Choose a Miami waterproof toothbrush for Miami beach toothbrush trips?

Key Advantages of Professional-Grade Home Teeth Whitening Devices

.jpg)

Grip Fatigue with Noise Pollution – Design Flaw?

.jpg)

Manhattan Replacement Heads Sync with NYC App Connectivity?

.jpg)

Are Runtime Drop and Thermal Failure Related?

Can a Wireless Charging Coil Benefit the Design of a Portable Water Flosser?

.jpg)

Is Button Malfunction Causing Uneven Bristles Disaster?

What is the Function of the Gravity Ball Design of the water Flosser?

Is the Water Flosser Worth Buying?

Where to Find Affordable Electric Toothbrush Wholesale from a Waterproof Electric Toothbrush Supplier?

.jpg)

Orlando Travel Toothbrush – Powsmart Travel Design with USB-C Charging