In advanced whitening systems, achieving a high Quantum Yield is essential for maximizing the effectiveness of a Smart Timer Whitening Kit. By ensuring that a greater proportion of absorbed light energy drives the intended chemical reactions, manufacturers can deliver predictable whitening performance that aligns precisely with time-controlled treatment protocols.

Quantum Yield measures how efficiently absorbed photons trigger whitening reactions. A higher value means more effective stain breakdown per unit of light exposure, allowing Smart Timer Whitening Kits to achieve consistent results within predefined treatment durations.

Smart timers rely on predictable reaction kinetics. When Quantum Yield is optimized, each timed cycle produces a reliable level of whitening, reducing variability and enhancing user confidence in automated treatment programs.

Efficient photochemical performance allows manufacturers to reduce light intensity or exposure time without sacrificing efficacy. This improves safety margins and extends component lifespan in timer-controlled whitening kits.

High Quantum Yield minimizes performance differences caused by variations in positioning, ambient conditions, or enamel characteristics. This ensures that the Smart Timer Whitening Kit delivers uniform results across a broad user base.

Optimized formulations and LED wavelengths aligned for high Quantum ensure smooth integration between chemical gels and optical components. This synergy enhances overall system efficiency and reduces wasted energy.

Quantifiable Quantum Yield data supports repeatable testing and validation. Manufacturers can use these metrics to verify that each production batch meets defined performance standards for smart, time-regulated whitening systems.

For B2B manufacturers, optimizing Quantum Yield is a strategic approach to unlocking the full potential of a Smart Timer Whitening Kit. By aligning photochemical efficiency with intelligent timing control, manufacturers can deliver safer, more reliable, and highly differentiated whitening solutions. Contact us

.webp)

Why Integrate an Electric Toothbrush PCBA Solution with a Wireless Charging Toothbrush OEM for Seamless Production?

Does an FDA Approved Device Inherently Guarantee Sensitivity Reduction?

.jpg)

Navigating Electric Toothbrush Import Regulations?

Is Your Bulk Material Sourcing Strategy Backed by Robust Quality Certification Support?

Does Black Electric Toothbrush ODM Face Handle Corrosion?

How Does Electric Toothbrush Recycling Work in Seattle?

.jpg)

Is Tooth Sensitivity with Enamel Erosion Whitening’s Side Effect?

.jpg)

Electric Toothbrush with Wireless Charging OEM

.jpg)

Is Dental tourism viable for Kirkland services?

.jpg)

Texas Flag Pattern Toothbrush

Does Your PCB Assembly Service Integrate Seamlessly with a Waterproof IPX7 Solution for Durable Oral Care Devices?

.jpg)

Adult Electric Toothbrush Wholesale for Global Brands and Distributors

How to Secure the Best Wholesale Price for Electric Toothbrush Export?

Five benefits of using a Wave electric toothbrush

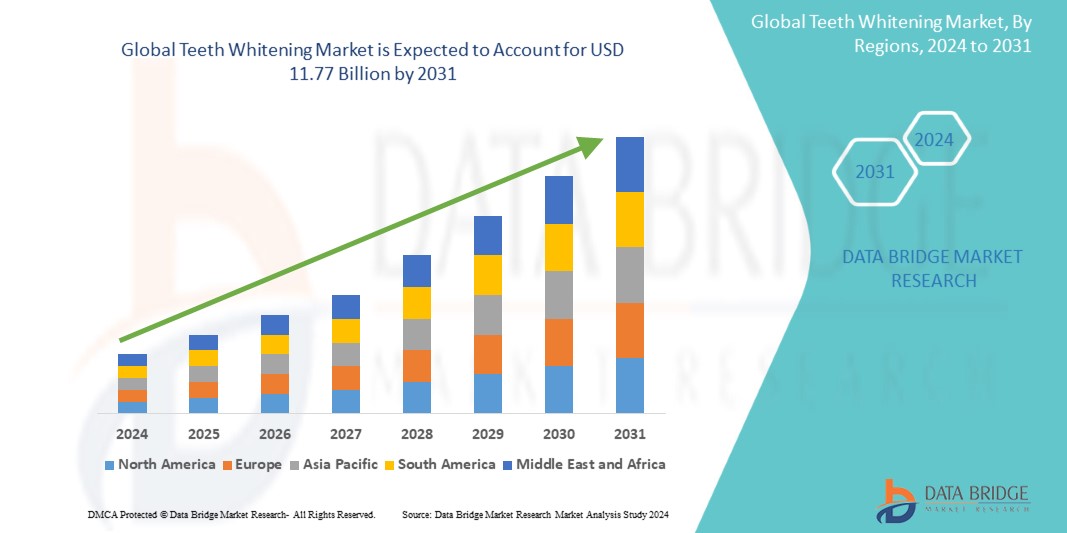

Global teeth whitening Device Market : Fastest Growing Regions and Consumer Group Portraits

How Does Water Tank Molding Design Integrate with a Gravity Feed System?