In the competitive world of oral care products, choosing the right Electric Toothbrush Handle Processes can make or break your brand. As an OEM looking to balance cost vs. quality, understanding how different handle production methods impact performance, design, and durability is essential. This guide breaks down key factors and offers practical insights to help you make informed manufacturing decisions.

The electric toothbrush handle is more than just a shell — it’s the core of user experience. It houses the motor, battery, and control components while providing comfort and safety during daily use. A well-designed handle offers ergonomic comfort and a durable grip design that prevents slippage even with wet hands. The choice of materials and production process directly influences not only how the toothbrush feels but also how long it lasts in the consumer’s hands.

When developing an OEM product, there are several main Electric Toothbrush Handle Processes to consider:

Injection Molding: Ideal for mass production, offering consistency and precision in shaping complex handle designs. It’s widely used for achieving smooth finishes and tight tolerances.

Overmolding: Combines hard and soft materials to enhance the handle’s durable grip design, improving comfort and aesthetics.

CNC Machining: Offers high precision and premium quality, often used for prototypes or luxury toothbrush handles.

Die Casting: Provides strong, metallic finishes for high-end or specialized models, though at a higher cost.

Each process has distinct advantages depending on your priorities—volume, texture, cost, and design flexibility.

Balancing OEM cost vs quality is one of the biggest challenges when selecting a handle process.

Low-cost methods like single-shot injection molding are suitable for entry-level models but may limit customization and long-term durability.

Mid-range processes such as overmolding offer better user experience with a modest cost increase.

Premium methods like CNC machining deliver exceptional quality but may exceed your target production budget.

The key is to align your brand positioning with your process choice—entry-level, mid-tier, or luxury.

The handle’s feel, weight, and longevity depend heavily on the materials used. Common choices include ABS, PC, and TPE for plastic components, while aluminum or stainless steel may be used for upscale designs. Finishing processes—such as polishing, texturing, or coating—also impact user perception and performance. A good manufacturing processes guide should help OEMs evaluate the trade-offs between aesthetics, durability, and cost.

Consumers often judge product quality by how it feels in the hand. A durable grip design isn’t just about comfort—it’s about safety, especially in wet bathroom environments. Overmolding or dual-material designs allow for textured or rubberized surfaces, offering a premium feel without compromising cost efficiency. Testing for wear resistance and chemical stability (e.g., exposure to toothpaste or mouthwash) ensures long-term reliability.

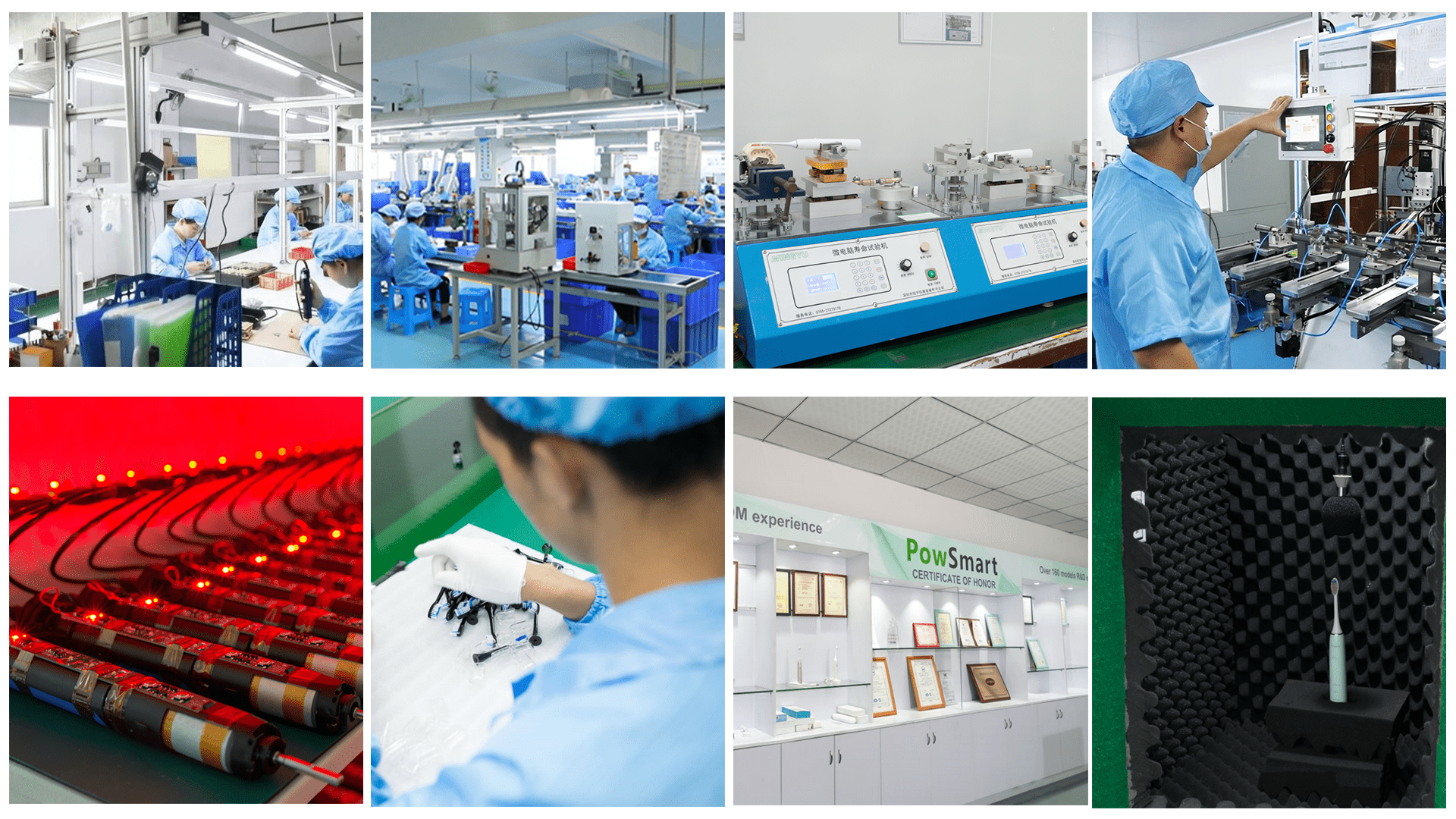

Selecting an experienced manufacturing partner is as important as choosing the process itself. Look for factories with proven expertise in electric toothbrush handle production, in-house tooling capabilities, and a track record of OEM cost vs quality optimization. Transparent communication, prototype validation, and consistent quality control can prevent costly redesigns later in production.

For OEMs in the oral care industry, understanding electric toothbrush handle production is vital to achieving the right balance between cost, quality, and brand positioning. By following a structured manufacturing processes guide and partnering with a reliable factory, you can deliver products that not only look premium but also perform reliably — from the first brush to the thousandth.https://www.powsmart.com/

.jpg)

Head Detachment with Tank Cracks—Replace All?

How Does a Teeth Whitening OEM Optimize Formulas for a Fast-Acting Whitening Gel?

As Young People Pay More Attention to Their Teeth, What New Trends Are Emerging in Oral Care?

.jpg)

Why Are Button Responsiveness Declines Tied to Battery Lifespan Inconsistency?

.jpg)

Cost-Effective Customization: Balancing Quality and Price in OEM Toothbrushes

.jpg)

How often should you change your brush head for optimal cleaning?

Analysis of the Core Competitiveness of Electric Toothbrushes: How to Win the Market Through Technological Innovation?

Is Red Light Therapy Popular in Europe? Market Insights for Oral Care Brands

How Does Advanced Whitening Gel Formulation Cater to Sensitive Teeth Whitening Needs?

.jpg)

Anti-Bacterial Electric Toothbrush Head Technology

comprehensive oral care solutions: Why Consumers Prefer Them

Optimizing Electric Toothbrush Shape: An OEM Guide to Grip and Maneuverability

Can I Use an Electric Toothbrush in the Shower?

.jpg)

Bellevue Wholesale Electric Toothbrush

Electric Toothbrush Demo Units – OEM Manufacturing for Dental Offices

Top Water Flosser and Toothbrush Combo in San Diego?