As the personal care market evolves, Next-Gen Electric Toothbrushes are no longer just about cleaning teeth—they’re becoming smart, connected devices that merge oral hygiene with lifestyle and health tracking. For brand owners seeking manufacturing partners, there’s a growing opportunity to differentiate with smart toothbrush technology. This blog explores how OEM collaborations can unlock value, enhance product portfolios, and position your brand at the forefront of innovation.

The toothbrush market has shifted from manual to electric, and now toward Smart Features for Next-Gen Electric Toothbrushes. Features such as Bluetooth connectivity, AI-driven brushing analysis, and app integration appeal to health-conscious consumers who value personalized care. OEM manufacturers with expertise in electronics and IoT integration can help brands deliver these advanced solutions efficiently.

One of the strongest selling points in how to differentiate your OEM electric toothbrushes lies in personalization. Consumers want toothbrushes that adapt to their habits—tracking pressure, timing, or even areas frequently missed during brushing. Smart sensors and machine learning algorithms can provide data-driven feedback, helping brands stand out in a crowded market.

Today’s smart toothbrush technology doesn’t exist in isolation. Products that can sync with broader health ecosystems—like fitness trackers, wellness apps, or dental care platforms—create added value for end-users. OEM manufacturers that already have experience in cross-device integration can help brands leap ahead.

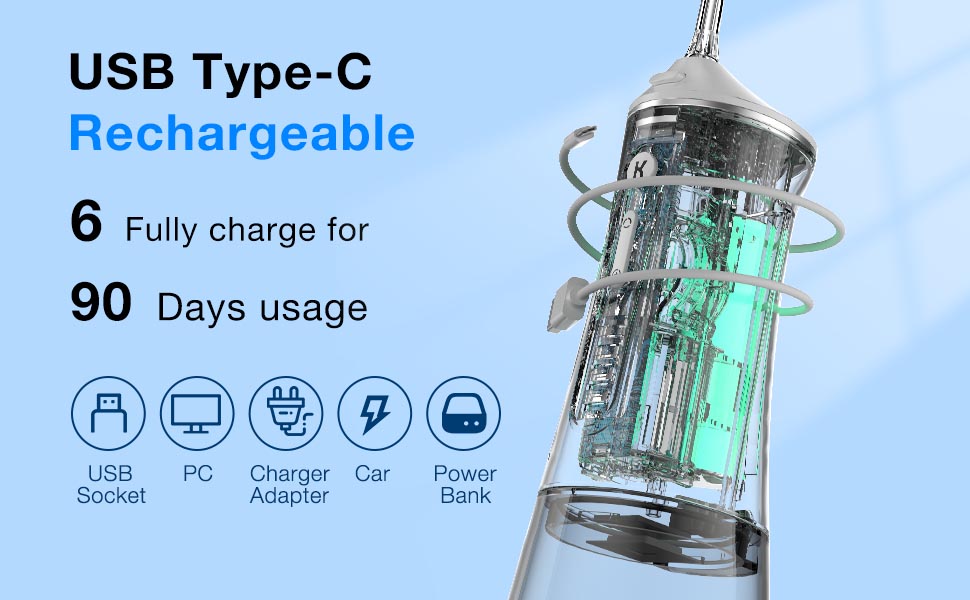

Consumers expect convenience and eco-conscious design. Extended battery life, wireless charging, and recyclable materials can be built into Next-Gen Electric Toothbrushes. Partnering with an OEM who is investing in sustainable technologies will not only support environmental goals but also strengthen your brand’s reputation.

Smart doesn’t just mean innovative; it also means safe. OEM collaborations ensure compliance with international regulations such as CE, FDA, or ISO standards. A reliable OEM partner helps brands navigate certifications, reducing time-to-market and risk while ensuring Smart Features for Next-Gen Electric Toothbrushes meet quality benchmarks.

Launching a next-gen device requires precision in R&D, tooling, and mass production. OEM partners with proven track records in electronics and healthcare can shorten development cycles, helping you deliver smart toothbrush technology faster while maintaining reliability and scalability.

The future of oral care lies in connected, intelligent devices that offer more than just cleaning power. By collaborating with the right OEM, your brand can integrate Smart Features for Next-Gen Electric Toothbrushes, enhance customer experiences, and ultimately capture market share. If you’re exploring how to differentiate your OEM electric toothbrushes, the path forward is clear: leverage smart features, sustainability, and compliance to deliver innovation that truly resonates with today’s consumers.

.jpg)

Blue Light Whitening Device Wholesale

How Does a Smart Timer Water Flosser Enhance the Functionality of a Home Countertop Irrigator?

.jpg)

Professional Teeth Whitening Device Factory for OEM Projects

How blue LED teeth whitening work?

How Long is the Battery Life of Electric Toothbrushes on the Market?

Why Market Orthodontic Oral Care Products Through a Dental Clinic Partnership Program?

.jpg)

ADA Style Electric Toothbrush for OEM Buyers | Gentle, Safe & Professional Sonic Cleaning

Building Quality Water Flossers: Essential Standards for Home Use & OEM Production

.jpg)

Understanding Water Flosser Compliance Certification for Global Markets

.jpg)

How does a rancher toothbrush Texas stand up to the lone star toothbrush challenge?

.jpg)

LED Oral Beauty Device Manufacturer for OEM & Private Label Dental Brands

Is High-Frequency Vibration Harmful to Gums?

.jpg)

Custom Light Electric Toothbrush OEM Manufacturing

Is Stain Removal Rotating Brush’s Motor Corrosion a Hidden Problem?

.jpg)

Pulse Instability with Noise Spikes – Motor Dying?

.jpg)

UV toothbrush sanitizer effectiveness