In the realm of electric toothbrush production, the correlation between brush head blockage and motor stalling is a significant issue that manufacturers cannot ignore. While consumers often attribute power interruptions to battery issues, internal evaluations reveal that clogged or obstructed brush heads are a leading cause of motor stalling, directly affecting product reliability and customer satisfaction. Is this problem avoidable? Let’s explore its origins and potential solutions.

Brush head blockage occurs when:

Over time, these factors create mechanical resistance that the motor cannot overcome, leading to system failure.

When brush head blockage occurs:

From the user’s perspective, this presents as sudden motor stalling or intermittent shutdown during brushing sessions. Company web:https://www.powsmart.com/product/electric-toothbrush/

Production flaws contributing to blockage include:

Attention to these production processes is essential to minimize blockage risks at source.

Manufacturers can implement the following strategies to prevent motor stalling from brush head blockage:

Combining mechanical precision with intelligent electronic protection offers a comprehensive solution.

To proactively catch blockage risks:

Continuous improvement through quality tracking ensures reliable prevention of brush head-related failures.

From a B2B perspective:

By eliminating brush head blockage risks, manufacturers secure both product longevity and customer trust.

Is motor stalling caused by brush head blockage? In many cases, yes. However, through optimized design, precise manufacturing control, and smart electronic safeguards, this preventable problem can be effectively eliminated. Proactive engineering ensures that your electric toothbrush products deliver seamless, reliable performance across their full lifecycle. Contact us

.jpg)

.jpg)

Do Nylon Toothbrush Bristles Release Microplastics? A Manufacturer’s Insight

.jpg)

Cordless Water Flosser for Family Use – Portable Home Oral Hygiene Solutions

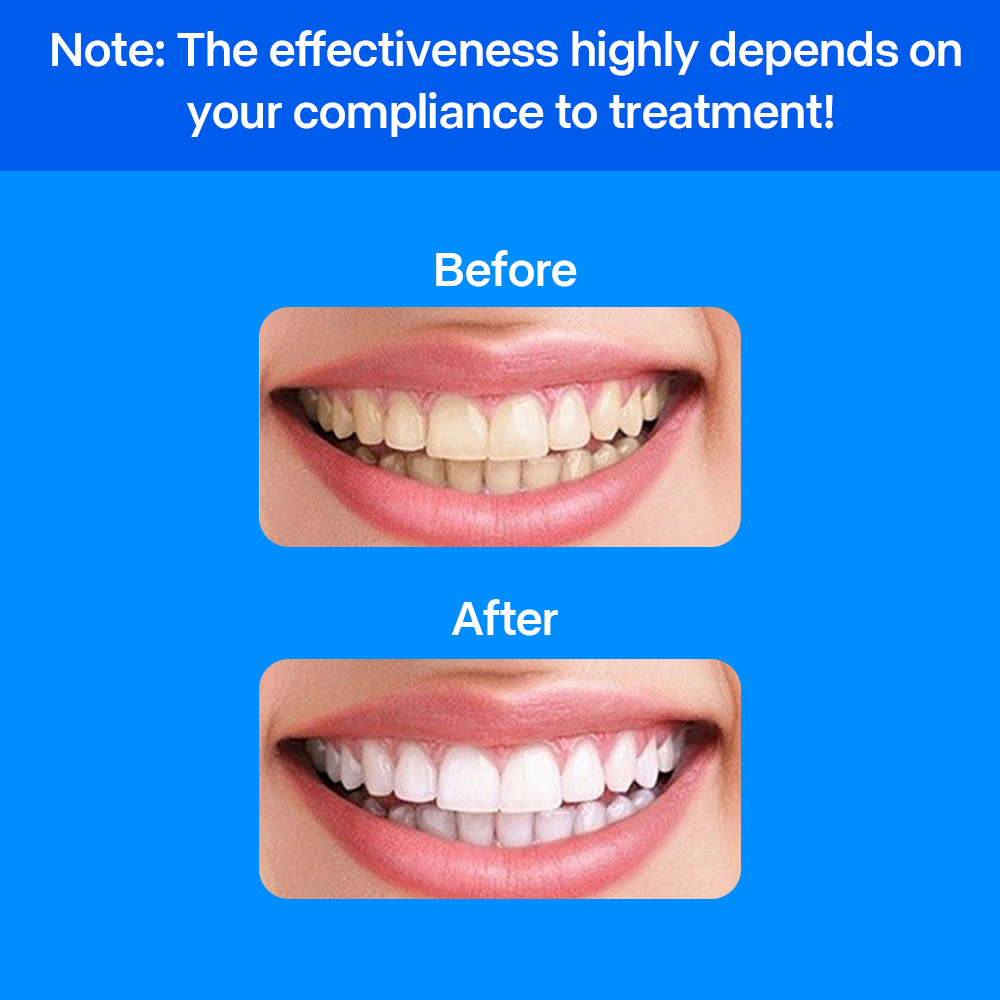

Introduction of 5 Important Teeth Whitening Products in Oral Care and Their Pros and Cons

How Does OEM Whitening Kit Development Cater to a Portable Whitening Kit Supplier’s Needs?

The Growing Potential of the Oral Care Business: Trends, Opportunities & Market Insights

Why Does My Electric Toothbrush Only Vibrate but Not Oscillate?

Why use Quad-brush Synchronization with Vortex Chamber Technology in advanced flossers?

.jpg)

PowSmart’s Commitment to Quality: What Sets Our Oral Care Products Apart

.jpg)

Can a custom Texas brush deliver a big Texas brush clean?

.jpg)

How Does Water Flosser Tank Manufacturing Integrate with Water Flosser Accessory Production?

Safety of Water Flosser on Gingival Health: Clinical Evaluation

.jpg)

Can Electric Toothbrush Charging Failures Cause Gum Bleeding?

The Revolutionary Impact of Gravity Ball Design on Water Flosser Performance

What Options Are Available for the Appearance and Shape of an Electric Toothbrush?

Comparing Button Types in Electric Toothbrushes: Which is Best for Your Product?

.jpg)

Fourth of July Red Blue Electric Toothbrush