In high‑performance spray systems, unstable spray patterns often translate directly into user discomfort, whether due to uneven coating, inconsistent cleaning pressure, or sudden pressure spikes. Moreover, an erratic jet can accelerate component wear and damage end‑use surfaces. In this blog, we explore why jet instability occurs, how it contributes to user discomfort, and offer practical strategies to diagnose and resolve these challenges for a smoother, more reliable operation.

First, it’s essential to understand the root causes behind unstable spray:

By isolating which of these factors predominates in your system, you can focus optimization efforts more effectively.

Furthermore, user discomfort often stems from uneven jet behavior:

In regulated industries—such as food processing or healthcare—this discomfort also raises compliance risks if clean‑down or coating standards aren’t met uniformly.Company Web:https://www.powsmart.com/product/electric-toothbrush/

To pinpoint issues, adopt a multi‑pronged diagnostic approach:

Combining objective measurements with subjective operator reports yields a holistic view of both technical and human factors.

Once you’ve diagnosed the root causes, consider these targeted remedies:

These engineering enhancements directly reduce the mechanical drivers of unstable spray.

Additionally, addressing user discomfort requires attention to human‑machine interaction:

Together, these steps ensure that even a technically optimized spray system remains comfortable for daily use.

Finally, continuous innovation is key to staying ahead:

By blending cutting‑edge technology with human‑centered design, manufacturers can deliver spray systems that are both high‑performance and user‑friendly.

Conclusion

Unstable spray patterns and the resulting user discomfort represent intertwined technical and ergonomic challenges. Through systematic diagnosis, targeted engineering fixes, and operator‑focused improvements, you can achieve stable jets, consistent performance, and a comfortable user experience. In an increasingly competitive market, these best practices will help ensure both product quality and customer satisfaction.

Interested in optimizing your spray systems? Contact us today to discuss custom solutions that balance precision and comfort.

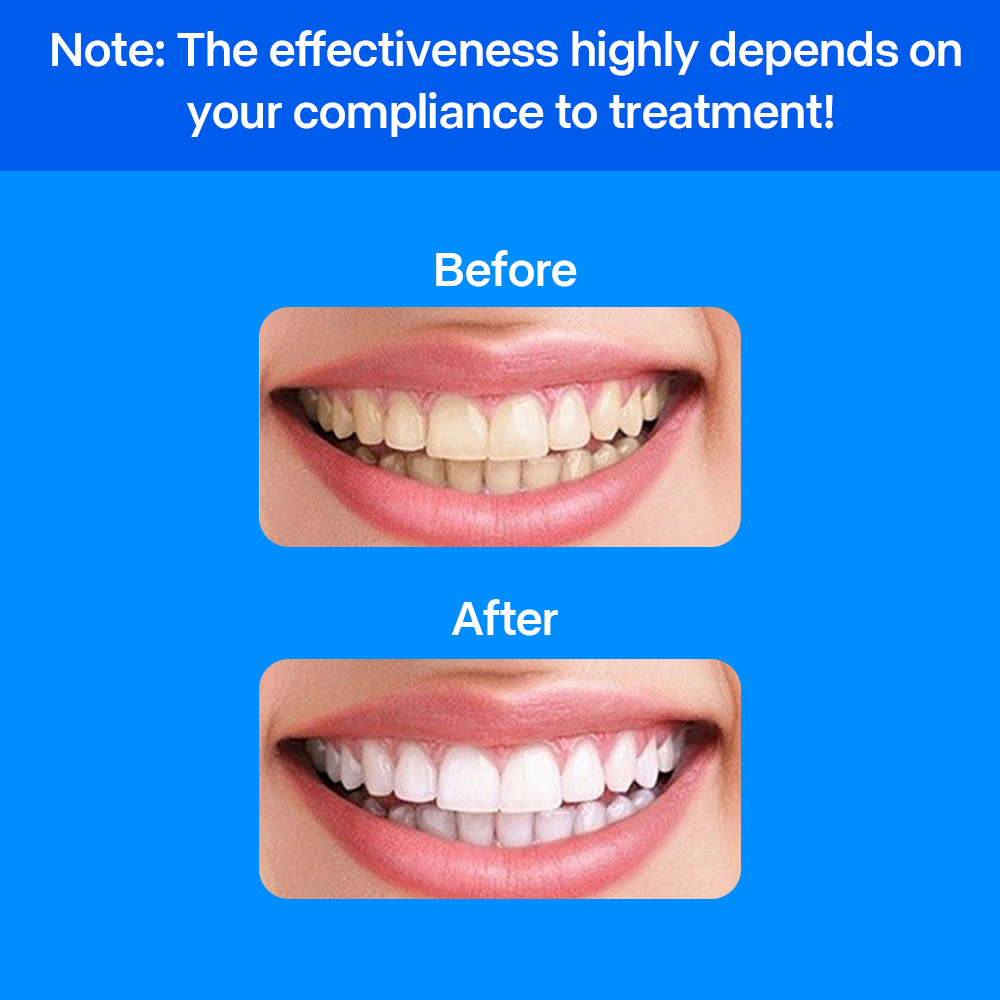

Different Ways to Whiten Teeth

Tips for Preventing Mold in Water Flosser Tanks

The Workmanship of Electric Toothbrushes

Preventing Mold in Water Flosser Tanks: Silver Ion vs. UV Sterilization

What are the advantages of ultraviolet sterilization water flosser?

.jpg)

Is Your Kids’ Electric Toothbrush Too Loud?

.jpg)

How to Clean Dirty Ports and Seal Deterioration?

.jpg)

Is Battery Swelling Causing Pressure Loss?

water Flosser Technology Innovation Leads to New Oral Care Trends

.jpg)

How Dangerous Are Jet Instability and Power Surges?

Ideal Pressure Settings for Sensitive Gums: Dentist Recommendations for Water Flosser Users

Custom Your Electric Toothbrush or Water Flosser Brand Now!

Dentist’s Guide: Choosing the Right LED Whitening Device for Stains

Can a Bangalore AI toothbrush boost your Efficient brushing tech routine?

Modern technology in oral care: innovative products and services

Difference between sonic toothbrush and sweeping electric toothbrush