In today’s competitive marketplace, even minor issues in product ergonomics can have far-reaching consequences. Recently, companies have noted that Handle Grip Slippage may not only compromise device usability but could also be linked to Sensitivity Flare-Ups in users. This blog examines how grip instability can affect user comfort and product performance, exploring the causes, impacts, and actionable solutions to address this growing concern.

Modern consumers expect products that not only function flawlessly but also offer a secure, comfortable user experience. In many sectors—from hand-held power tools to personal care devices—a reliable grip is paramount. Handle Grip Slippage undermines this expectation by causing inadvertent movements during use, which may stress or irritate the user’s hand and skin. In some cases, these issues have been observed to trigger Sensitivity Flare-Ups—a series of localized reactions such as redness, discomfort, or heightened tactile sensitivity. As a result, manufacturers must align product design with rigorous ergonomic and performance standards that address both functional reliability and user well-being.

To effectively mitigate these issues, it is essential to identify the root causes behind Handle Grip Slippage. Factors contributing to this problem may include:

Understanding these factors helps manufacturers develop targeted strategies to enhance grip reliability and ensure consistent user performance.

Once the handle begins to slip during use, the repeated adjustments and involuntary movements required to maintain control can lead to overexposure of the skin to frictional forces. This can result in Sensitivity Flare-Ups over time. When a handle does not maintain a stable grasp:

These physiological responses can undermine user confidence and, if persistent, may lead to a decline in repeat usage and overall customer satisfaction.

Addressing Handle Grip Slippage requires a comprehensive approach that starts with material and design choices. Key engineering challenges include:

These engineering considerations, when executed properly, set the stage for mitigating both Handle Grip Slippage and the resultant Sensitivity Flare-Ups.

To tackle these challenges, manufacturers can implement several robust strategies:

By employing these strategies, companies can create products that offer both reliable grip and enhanced user comfort, reducing the risk of sensitivity issues.

Looking ahead, the convergence of smart manufacturing, AI-driven design tools, and advanced material science offers promising avenues for further improvements. Future developments may include:

Innovations in these areas will help manufacturers not only overcome the challenges of Handle Grip Slippage but also preempt Sensitivity Flare-Ups, thereby securing a competitive advantage in the marketplace.

Conclusion

The relationship between Handle Grip Slippage and Sensitivity Flare-Ups underscores the critical importance of robust ergonomics and high-quality materials in product design. By thoroughly understanding the root causes, investing in innovative solutions, and maintaining rigorous quality control, manufacturers can mitigate these issues and enhance both product performance and user experience. In an increasingly demanding market, continuous innovation and proactive design are essential to sustaining customer trust and long-term success.

Interested in optimizing your handle design to eliminate grip slippage and mitigate sensitivity issues? Contact us today to discover tailored solutions that drive both performance and customer satisfaction.

.jpg)

Professional Whitening System Bulk Supply for Global Retailers

.jpg)

Seal Degradation Leading to Biofilm Regrowth – Preventable?

.jpg)

LED Oral Beauty Device Manufacturer for OEM & Private Label Dental Brands

.jpg)

Practical Valentine’s Day Gift for Husband Electric Toothbrush | Powsmart

.jpg)

Pregnancy Contraindications and Chemical Burn Risks in Whitening: What You Must Know!

.jpg)

Electric Toothbrush Design Customization for OEM and Private Label Brands

.jpg)

Battery Drain and Compatibility Issues Triggering Claims?

Navigating Toothbrush Import Regulations: What Every Buyer Should Know?

Is it True or a Gimmick that Electric Toothbrushes Can Remove Dental Plaque? – Suppliers Tell You the Truth

Why an IT professional toothbrush needs a Desk charging station

.jpg)

Dallas Toothbrush Sale: Factory-Direct Discounts with Global Shipping

.jpg)

LED indicator water flosser supplier

Need an OEM Electric Toothbrush with Comprehensive Custom Branding Service?

.jpg)

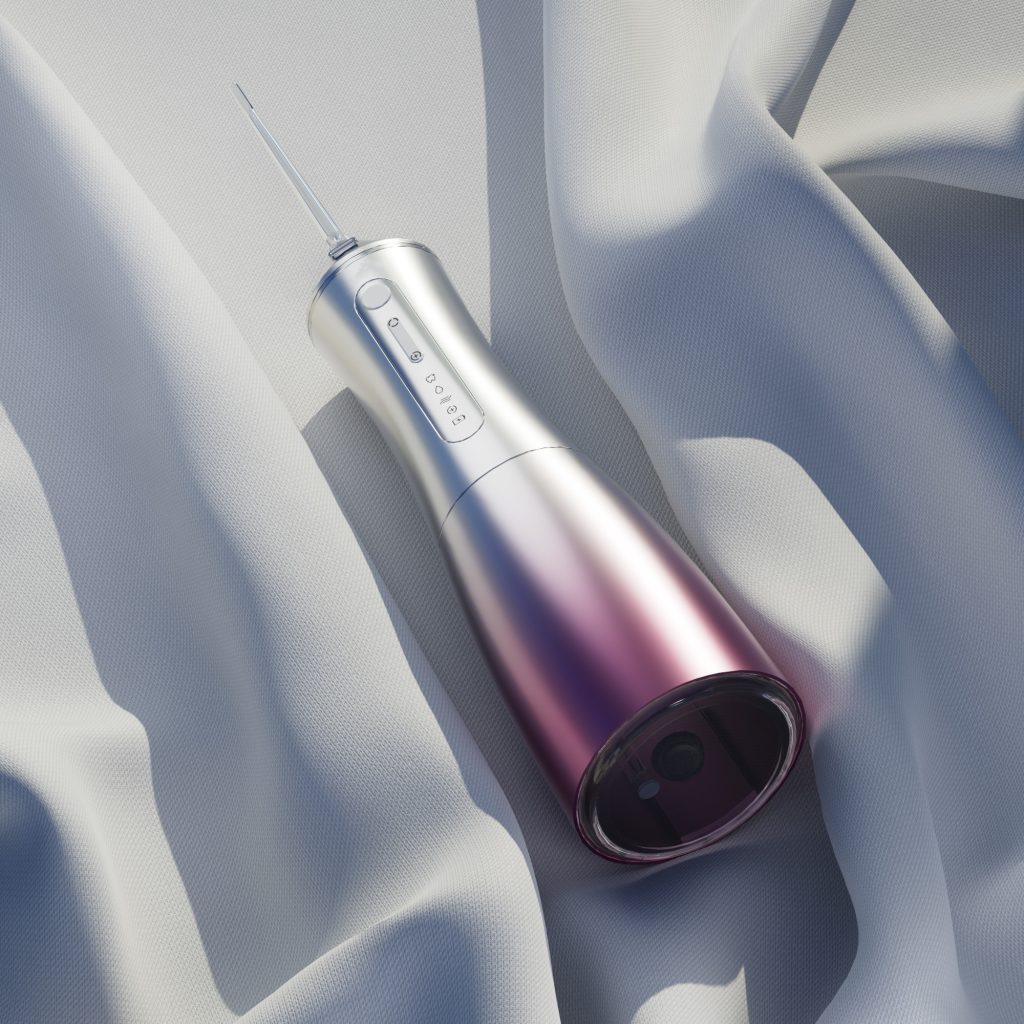

Compact Cordless Water Flosser OEM Manufacturing | Portable Oral Care Solutions

.jpg)

Travel Toothbrush with UV Sterilizer Wholesale | OEM Bulk Amenity Solutions

Best Tips for Brands Before Deciding to OEM Water Flossers