As the demand for at-home cosmetic dental solutions grows, red and blue light teeth whitening devices are increasingly gaining traction in both developed and emerging markets. For startup brands and new entrants, navigating small batch production and OEM sourcing can be complex. This article outlines key strategies for purchasing in small quantities while identifying a reliable Low MOQ OEM factory for your brand’s trial production.

Small batch production is no longer just a tactic for boutique businesses — it has become a practical approach for emerging oral care brands aiming to minimize risk and validate market response. By opting for small batch orders, businesses can:

Partnering with a teeth whitening device manufacturer that supports small batch production enables a brand to maintain agility while exploring innovative technologies like red and blue light dual-function therapy.

Finding a qualified Low MOQ OEM factory is critical for success. When sourcing an OEM partner for teeth whitening devices, especially those incorporating LED red/blue light features, consider the following criteria:

Trial production cost planning is essential before scaling up. Small batch production can have a slightly higher per-unit cost compared to mass production, but this is offset by reduced upfront investment and risk. To estimate your trial production cost:

Moreover, working with an experienced teeth whitening device manufacturer helps streamline the process — from prototyping to regulatory support — allowing your brand to focus on marketing and customer acquisition.

For brands seeking to enter the red and blue light whitening device market, starting with a small batch order from a qualified Low MOQ OEM factory is a smart strategy. It minimizes risk, validates market interest, and allows you to iterate quickly. By carefully evaluating trial production cost and working closely with an experienced teeth whitening device manufacturer, your brand can take the first confident step toward scalable success.

.jpg)

Portable Whitening Lamp | Compact LED Light for Teeth Brightening

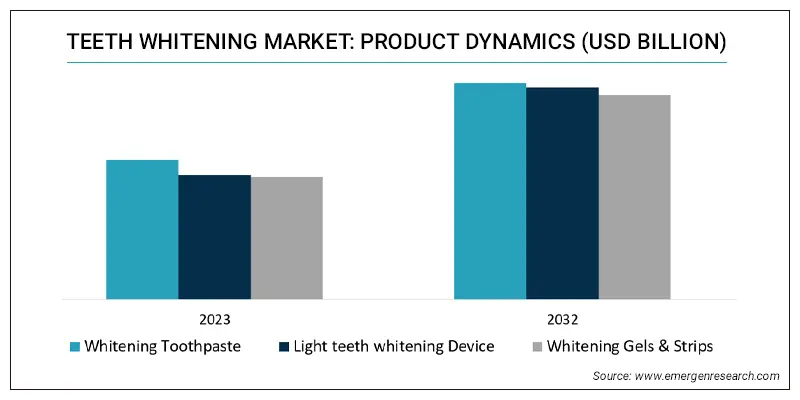

Analysis of Teeth Whitening Device Market Trends: The Functions and Designs That Consumers Will Pay Most Attention to in 2025

The Advantages of Teeth Whitening Devices: How to Enjoy Professional-Level Teeth Whitening Results at Home

sonic electric toothbrush factory

The Rise of Wireless Teeth Whitening Devices: Manufacturing Innovations

Frequency and Tips for Using Your At-Home Mouthpiece Recommended by Your Dentist

Optimizing the teeth whitening device production cycle: How Can Professional Manufacturers Shorten Delivery Time?

Things you should know about LED teeth whitening devices

.jpg)

Does Teeth Sensitivity Worsen Tetracycline Stains? New Whitening Side Effects!

.jpg)

LED teeth whitening device manufacturer | Professional Whitening Device OEM Factory

The Market is Growing Rapidly: Is There Still an Opportunity to Enter the Oral Irrigator Industry?

.jpg)

powsmart electric toothbrush factory

Custom Details of the Teeth Whitening Kit

Teeth whitening device OEM: In-Depth Cooperation Model from LOGO to Light Wave Customization

.jpg)

Home-Use Whitening Lamp OEM | Custom LED Dental Light Manufacturer

The Science Behind Cold Light Teeth Whitening: How Wavelength Impacts Whitening Results