Usually, As electric toothbrush manufacturers, we need the following production equipment, as follows:

Used to implant bristles into the holes of the brush head shell. It can accurately implant bristles according to the preset density, angle and arrangement. For example, when producing some electric toothbrush heads with special bristle arrangements (such as cross arrangement or wavy arrangement), the hair transplanting machine can accurately complete the task.

The bristles are fixed by a mechanical arm or a clamp. And then accurately inserted into the corresponding holes of the brush head shell. Some hair transplanting machines also have an automatic hair supply system to ensure the continuity of the bristle supply.

If we produce the brush head shell by injection molding, we need an injection molding machine. The injection molding machine can heat and melt the plastic particles. Inject them into a specific mold to form the shape of the brush head shell.

The injection molding machine is mainly composed of an injection system, a mold clamping system, a hydraulic transmission system, an electrical control system, etc. The injection system heats the plastic raw material and injects the molten plastic into the mold cavity through a screw or plunger, and the clamping system ensures that the mold is tightly closed during the injection molding process.

It is used to seal the brush head shell after the bristles are implanted. If we use glue seaing, we need special dispensing equipment to accurately control the amount of glue and the application position; if we use ultrasonic welding sealing, we also need an ultrasonic welding machine.

The dispensing equipment squeezes the glue from the rubber barrel by air pressure or screw propulsion. And the size, spacing and other parameters of the glue dots controll by programming. The ultrasonic welding machine uses high-frequency vibration to generate friction heat between plastic molecules, so that the two plastic parts are fused together under pressure.

It is to produce the plastic part of the electric toothbrush handle. Since the shape and structure of the toothbrush handle may be more complex, the injection molding machine is to meet different mold requirements. This ensure that the molded toothbrush handle meets the standards in terms of dimensional accuracy and appearance quality.

Also based on the principle of injection molding, the plastic raw material injected into the toothbrush handle mold, and the finished toothbrush handle will obtain by cooling and shaping.

If the electric toothbrush handle contains a circuit board, the mounter is to quickly and accurately mount electronic components (such as chips, resistors, capacitors, etc.) on the circuit board. This is very important for improving production efficiency and ensuring the assembly quality of the circuit board. The mounter uses a series of actions such as suction-displacement-mounting. A vacuum adsorption head to remove electronic components from the material belt or tray.

Used to install the battery into the toothbrush handle. This may include battery positioning fixtures, battery welding equipment etc. The battery installation equipment must ensure that the battery install in the correct position and the positive and negative poles connected correctly.

The battery positioning fixture fixes the battery in the correct position of the toothbrush handle through a mechanical structure. While the battery welding equipment melts the metal material at high temperature to achieve reliable electrical connection between the battery electrode and the circuit in the toothbrush handle.

Assemble the produced brush head and toothbrush handle. Some equipment can also perform simple torque tests to ensure that the brush head will not loosen easily after installation.

Perform a comprehensive functional test on the assembled electric toothbrush. Including testing the motor speed, torque, switching between different cleaning modes, battery power detection, charging function test (for rechargeable electric toothbrushes), etc. A special motor test bench is to measure the speed and torque values under different loads through sensors. A battery tester is to evaluate the performance of the battery by measuring the battery voltage, internal resistance and other parameters.

Used to check the appearance quality of the electric toothbrush, such as whether there are scratches and flaws on the surface, whether the color is uniform, etc. It may include a visual inspection system that can automatically identify appearance defects.

The visual inspection system uses a camera to collect the appearance image of the electric toothbrush. And then analyzes the pixel information in the image through an image processing algorithm. Comparing it with the preset qualified standards to determine whether there are appearance defects.

Downtown Chicago Electric Toothbrush Repair Services

Are Child safety Electric Toothbrushes Made from Materials?

Life cycle of Electric Toothbrushes! Its Components and Effects

The Role of Blue and Red Light in Teeth Whitening Devices You Should Know

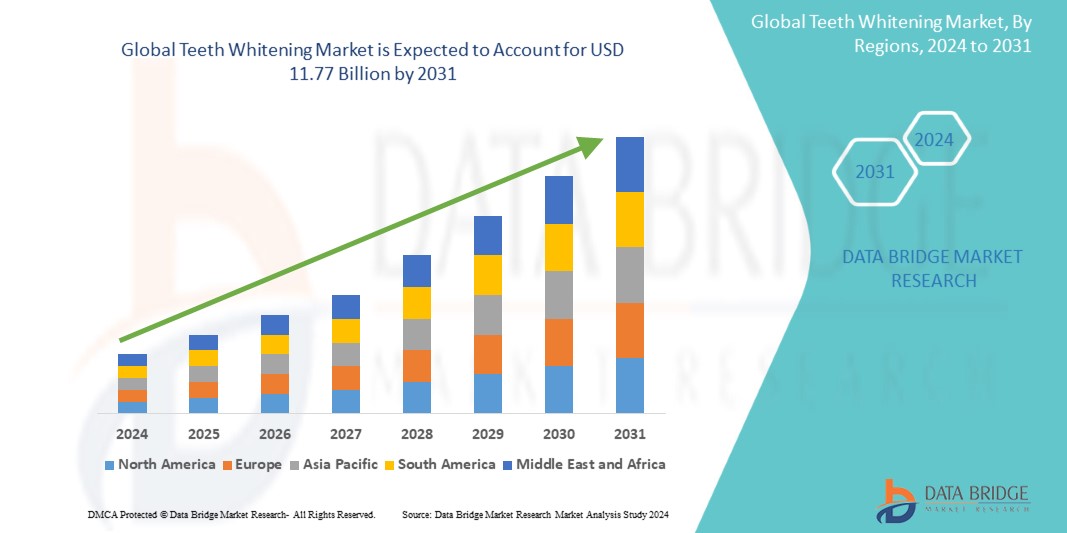

Global teeth whitening Device Market : Fastest Growing Regions and Consumer Group Portraits

.jpg)

Essential points to entering oral care market in Southeast Asia

How to Effectively Reduce the After-Sales Return Rate of Electric Toothbrushes

Can UV Light Degradation Affect Whitening Gel Leakage?

Sonic Toothbrush Motor Comparison: Magnetic Levitation vs. Traditional Motors

.jpg)

Reduce E-Waste: Sustainable Practices for Electric Toothbrush Manufacturers

How to Achieve a Win-Win Situation of “Consumption Upgrade” and “Cost Control”?

Can Teeth Whitening Gel Be Used Alone to Whiten Teeth?

Grip Fatigue with Noise Pollution – Design Flaw?

Enamel Erosion with Cavity Acceleration – Vicious Cycle?

Why Dentist Consultations Mitigate Home Treatment Risks?

Gel Crystallization with pH Imbalance – Toxic?

electric toothbrush heads Ultra Soft

electric toothbrush heads Regular Clean

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Electric toothbrush heads Charcoal Infused-Diamond

Customization Teeth Whitening Gel

electric toothbrush heads Deep Clean

electric toothbrush heads Charcoal Infuse-Round

Private Label Whitening Gel

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638