In recent quality feedback from users of oral care or personal hygiene products, complaints regarding plastic odor have drawn increasing attention—particularly when accompanied by symptoms like throat irritation. This has prompted an urgent question among product manufacturers and regulatory bodies: are such odors merely unpleasant, or are they signs of toxic materials or substandard production practices? In this blog, we will systematically examine the root causes and risks behind plastic odors, and provide six key points for manufacturers to address these safety concerns effectively.

Plastic odor often stems from the presence of volatile organic compounds (VOCs) released during or after the molding process. These compounds can be residual monomers, plasticizers, or by-products of polymer degradation. In many cases, the odor becomes more prominent when products are unpackaged or exposed to warm environments. Although slight off-gassing is common in freshly manufactured goods, excessive or persistent smells suggest possible issues in raw material selection or processing temperature control.

For some users, the presence of a plastic odor leads to mild throat irritation, dry cough, or a burning sensation. While this may be a sensory reaction in sensitive individuals, it may also indicate the release of low-level irritants such as formaldehyde, benzene, or phthalates—especially when poor-quality or recycled plastic materials are used. Even if the chemical levels do not exceed toxicity thresholds, chronic low-dose exposure could trigger discomfort in end-users and raise health concerns.

One of the most effective ways to prevent plastic odor and minimize potential throat irritation is through strict raw material control. Manufacturers must prioritize:

Avoiding recycled or unverified suppliers is critical. In addition, third-party lab validation of material purity and off-gas testing under simulated usage conditions can help ensure user safety and regulatory compliance.

Manufacturing-related factors also significantly impact odor intensity. Improper mold venting, excessive melt temperatures, or prolonged dwell times can cause resin degradation, releasing foul-smelling gases. To minimize odor:

Even the best materials will emit odors if processed incorrectly, making engineering oversight a crucial part of product quality.

Beyond molding, post-processing steps like ultrasonic welding, assembly adhesives, and packaging materials can also contribute to odor release. Therefore, manufacturers should:

Such holistic control measures reduce the risk of throat irritation in sensitive users and improve overall product acceptance.

To address user concerns about potential toxicity, manufacturers should build transparent product safety protocols:

By proactively communicating safety measures, brands can rebuild user trust and strengthen their reputation in markets sensitive to health-related product attributes.

Although plastic odor and throat irritation are not always indicators of toxicity, they serve as warning signs of potential issues in material selection, processing, or quality control. For B2B manufacturers, ignoring these symptoms may lead to regulatory risks, consumer dissatisfaction, and reputational harm. On the other hand, adopting a strict, science-driven manufacturing strategy—based on safe materials, precise process control, and transparent communication—ensures that your products not only smell clean but are clean and safe in every aspect. Contact us

-1.jpg)

.jpg)

The various functions of electric toothbrushes: gimmick or practical?

How to Prevention Toothache in the First Place?

How to Optimize the Waterproof Performance of Electric Toothbrushes: Insights from Manufacturers

Electric Toothbrush Recycling Seattle

.jpg)

Top 5 Factors When Selecting a UV Sterilizing Water Flosser Manufacturer

How to Solve the Problem of Low Battery in Electric Toothbrushes?

Chicago Black Friday: Best Electric Toothbrush Deals

Innovative technology and development trend of electric toothbrushes

.jpg)

Dallas Electric Toothbrush Private Label Services Including Custom Packaging

Is It Necessary to Replace the Brush Head of the Electric Toothbrush in 3 Months?

Is Your Water Flosser Leakage Due to Poor ESD Packaging?

Gift for Software Engineer Electric Toothbrush Bangalore

Sync Disruption Causing Taste Alteration – Tech Glitch?

.jpg)

Can Arizona hard water damage your Arizona mineral toothbrush?

How long does it take for LED teeth whitening kits to work?

The Importance of Water Resistance for Teeth Whitening Devices and Anti-Saliva Corrosion Structure

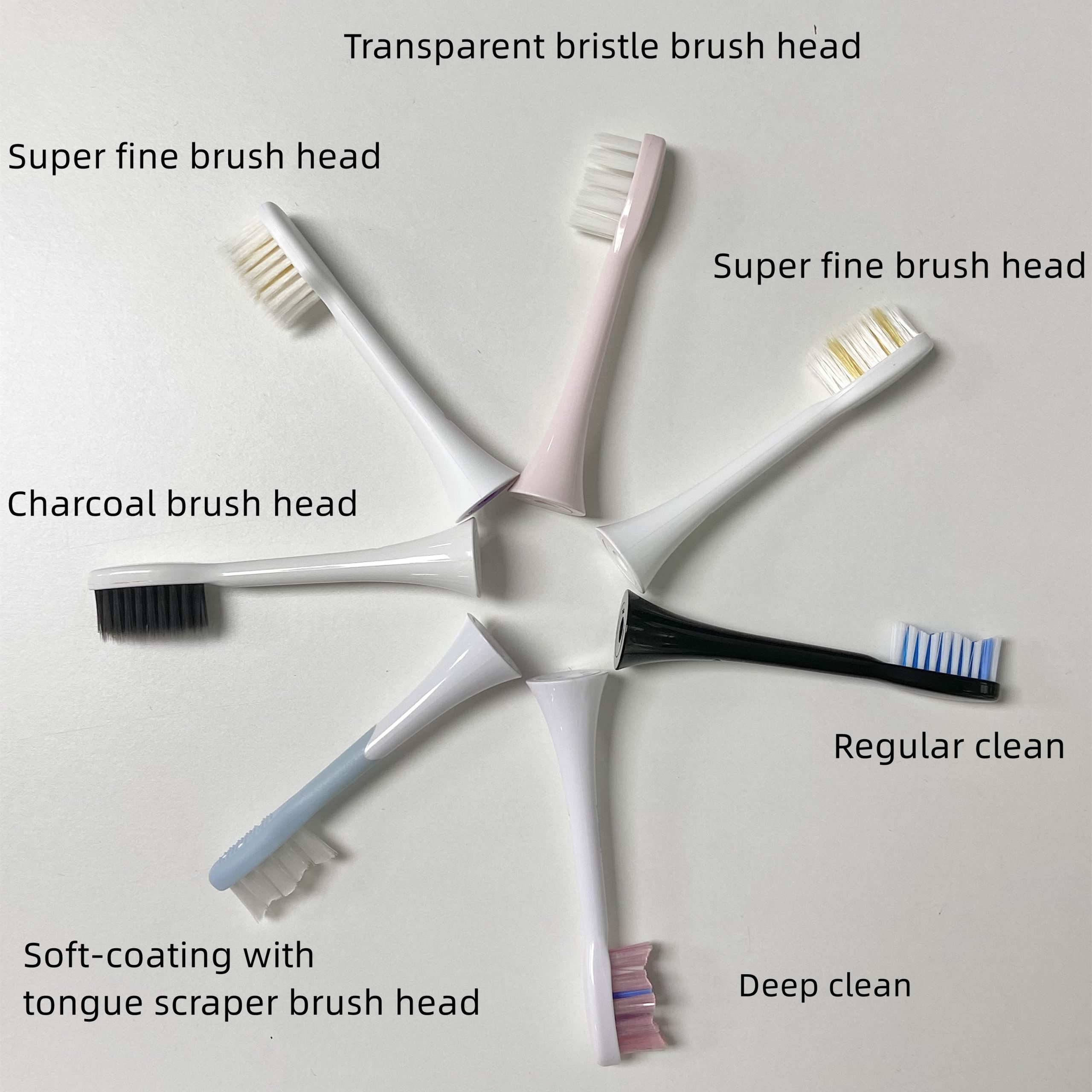

electric toothbrush heads Deep Clean

Private Label Whitening Gel

electric toothbrush heads Charcoal Infuse-Round

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Electric toothbrush heads Charcoal Infused-Diamond

electric toothbrush heads Ultra Soft

electric toothbrush heads Regular Clean

Customization Teeth Whitening Gel