When sourcing dental water flosser wholesale products, one critical yet often overlooked factor is water flosser nozzle production. The nozzle — being the most functional and user-contact component — directly impacts product performance, user comfort, and long-term durability. Manufacturers that manage in-house water flosser nozzle production gain substantial control over product quality, innovation speed, and cost efficiency.

In this blog, we’ll explore why in-house nozzle production matters, how it supports wholesale buyers, and what advantages it brings to brands working with professional oral care manufacturers.

In dental water flosser wholesale, precision is everything. The nozzle defines how effectively pressurized water is delivered to clean between teeth and along the gumline.

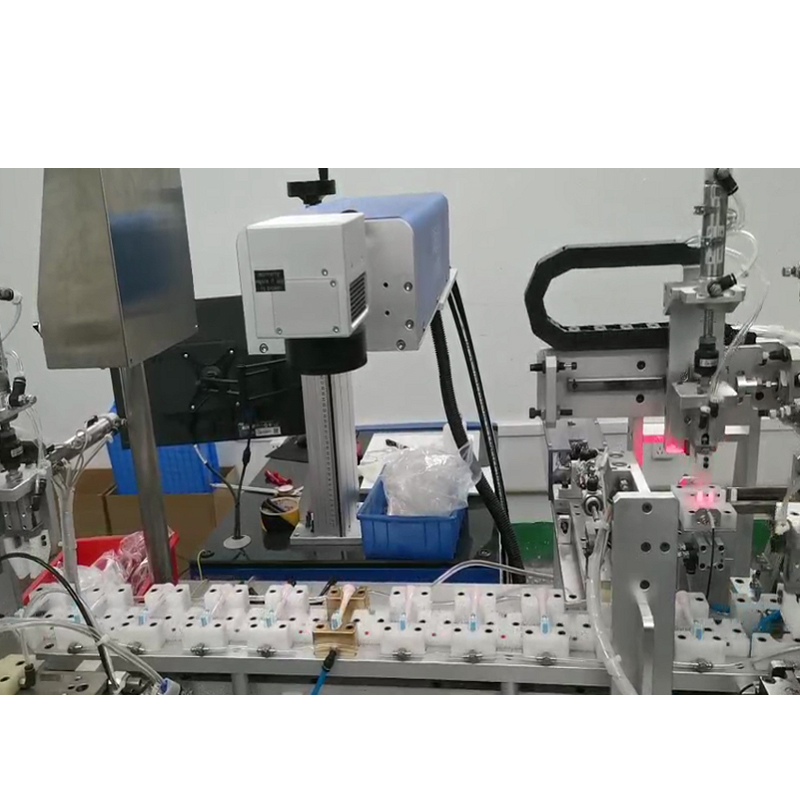

With in-house water flosser nozzle production, manufacturers can maintain extremely tight tolerances on nozzle diameter, material composition, and water pressure consistency. Internal control ensures every batch meets exacting performance standards — whether producing standard jet tips, orthodontic nozzles, or periodontal tips.

This results in better spray consistency, reduced leakage, and improved user satisfaction — qualities that are essential for brands looking to establish a premium reputation.

Manufacturers with in-house water flosser nozzle production can accelerate innovation cycles. Instead of outsourcing nozzle design or relying on third-party tooling, they can test new materials, shapes, and flow angles in-house — rapidly developing and refining prototypes.

For dental water flosser wholesale customers, this translates into:

This agility is a competitive advantage for distributors and retailers who need to refresh their oral care catalog regularly with innovative, user-friendly designs.

When production processes are managed internally, quality control becomes more comprehensive. Every nozzle undergoes pressure testing, material inspection, and durability assessment before assembly.

In water flosser nozzle production, this ensures:

For dental water flosser wholesale buyers, these quality measures guarantee consistent product reliability, fewer returns, and improved consumer trust.

Outsourcing nozzle components often adds hidden costs — including logistics, communication, and quality inspection expenses. With in-house water flosser nozzle production, these costs are minimized.

Manufacturers can better control raw material sourcing, streamline production flow, and reduce dependency on external suppliers. This leads to:

For dental water flosser wholesale clients managing bulk orders, cost efficiency and reliable delivery timelines are essential for maintaining profitability and customer satisfaction.

Private label and OEM customers often seek design differentiation — and in-house water flosser nozzle production makes this achievable. Manufacturers can customize nozzle angles, colors, markings, and branding elements according to each client’s specifications.

Whether your market focuses on travel-friendly flossers, high-pressure professional units, or children’s oral care devices, in-house nozzle customization allows the product to align with your brand identity and user experience goals.

For dental water flosser wholesale distributors, offering diverse nozzle designs under one brand strengthens market positioning and appeals to a broader customer base.

Choosing a manufacturer with in-house water flosser nozzle production isn’t just about immediate quality — it’s about forming a strategic partnership. Internal control over production enables continuous improvement in both efficiency and product design.

For long-term dental water flosser wholesale collaboration, this means your supplier can:

This reliability strengthens brand consistency and reduces the operational risks associated with multi-supplier coordination.

Investing in a manufacturer that offers in-house water flosser nozzle production provides measurable advantages — from improved quality control and faster innovation to lower costs and stable supply chains.

For brands and distributors in dental water flosser wholesale, partnering with a manufacturer capable of managing both core device assembly and under one roof ensures product excellence, customization flexibility, and long-term competitive strength.

🌐 Looking for a trusted OEM partner with full in-house nozzle production and bulk water flosser manufacturing capabilities? Contact our professional team today to discuss your project and customization requirements.

.jpg)

-1024x1024.jpg)

2025 Electric Toothbrush Promotional Sale: Opportunities for Brands to Scale with the Right Manufacturer

.jpg)

How an Oscillating-Rotating electric toothbrush removes plaque more efficiently

App Connected Toothbrush: OEM Development for Smart Oral Care

Oral Ulcers Fluorosis aggravation? Whitening Device Contraindications!

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?

Electric Toothbrush for Students: Budget-Friendly OEM Options

Whitening Gel Leakage Leads to Teeth Yellowing? Experts Issue Warning!

.jpg)

Taste Distortion Alongside pH Imbalance – Vicious Cycle?

Travel Electric Toothbrush | Portable Oral Care

Electric Toothbrush Gujarat | Modern Family Care

Smart Toothbrush for Professionals | Tech Lifestyle Care

Can a soft-bristle brush head designed for sensitive gums make your brushing process more comfortable?

Pump Seizure Plus Gingival Abrasion – Critical?

pH Imbalance Plus Taste Distortion – Toxic?

.jpg)

In-depth Analysis of the Logo Craftsmanship of Water Flossers

The Growing Potential of the Oral Care Business: Trends, Opportunities & Market Insights

electric toothbrush heads Ultra Soft

Electric toothbrush heads Charcoal Infused-Diamond

Customization Teeth Whitening Gel

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Regular Clean

electric toothbrush heads Deep Clean

Private Label Whitening Gel

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638