When channel partners report persistent nozzle clogging and water tank leakage, it undermines user confidence and drives up warranty costs. In this article, we explore six critical areas—from root causes to design optimizations and maintenance protocols—so B2B manufacturers can deliver water flossers that stay clog-free and leak-proof.

First, understanding why debris builds up in the tip helps prevent downtime:

By pinpointing these factors, manufacturers can target materials and geometries that resist clogging.

Next, even minor leaks from the reservoir compromise hygiene and safety:

Accurate failure analysis informs stronger sealing methods and robust tank geometries.Company web:https://www.powsmart.com/product/electric-toothbrush/

.jpg)

Moreover, choosing the right substances is pivotal:

These material upgrades form the first line of defense against both clogging and leakage.

Furthermore, structural enhancements can make a big difference:

When combined, these design features drastically reduce field failures.

In addition to product upgrades, clear user instructions keep devices operating smoothly:

Well-documented maintenance protocols cut down on service calls and extend product life.

Finally, to fully address nozzle clogging and water tank leakage, B2B partners should leverage:

This end-to-end approach ensures your water flosser products remain reliable, hygienic, and competitive in the marketplace.

Conclusion

By rigorously addressing the root causes of nozzle clogging and water tank leakage—through material selection, engineering refinements, maintenance guidance, and robust B2B support—manufacturers can dramatically reduce failures and boost partner satisfaction. Contact us to learn how our tailored solutions can fortify your next-generation water flosser lineup.

Wavelength of Whitening Teeth Device Blue Light (460–490nm) and Red Light (620–660nm)Configuration Guide

Hydrogen Peroxide Concentration & Motor Durability: Linked?

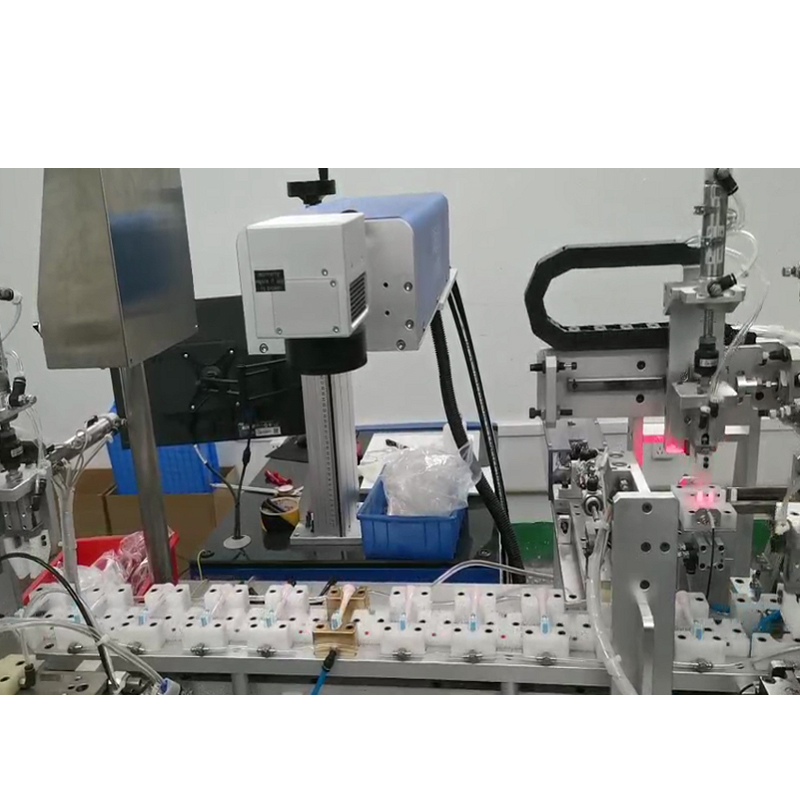

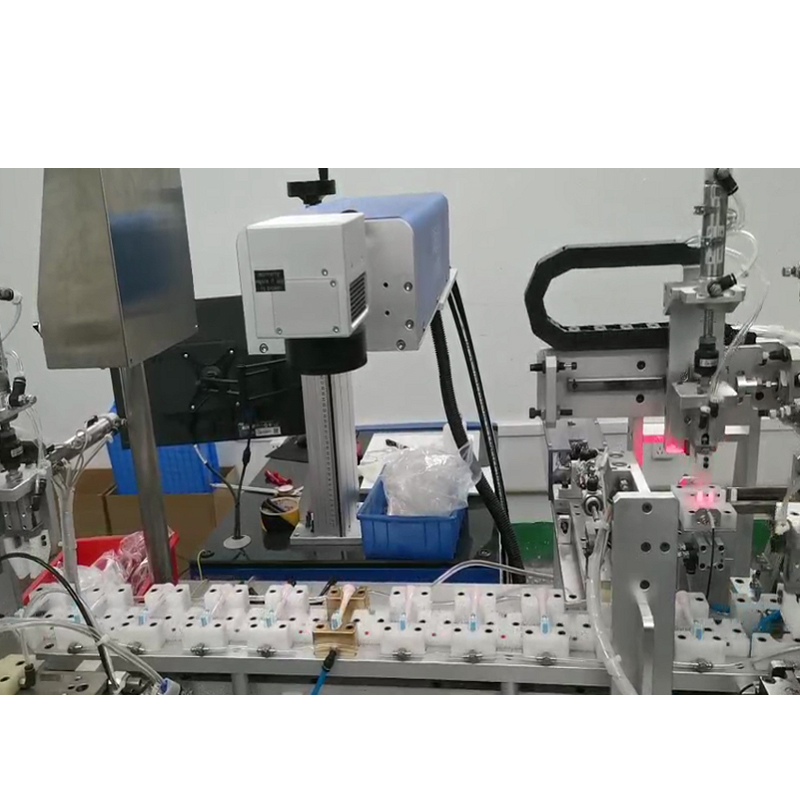

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?

Occlusal Discomfort Plus Salivary Alteration – Alarming?

.jpg)

Where to read a Bangalore gadget review for an App-connected toothbrush?

How Does Cold Light Wavelength Affect Bleach Decomposition?

How Does Gum Recession Relate to Maintenance Complexity?

Electric Toothbrush Production Process Diagram: Complete Process from Injection Molding to Assembly and Key Points of Quality Inspection

How to Deal with Sudden Tooth Sensitivity carefully?

Explaining the Teeth Whitening Device and How to Use It

-3-scaled.png)

Home vs. Professional Red and Blue Light Teeth Whitening Devices: Wavelength Stability and Energy Density Comparison

Gentle Electric Toothbrush for Sensitive Aging Gums

How much does it cost to manufacture a toothbrush?

How to Keep Teeth Clean with Braces: A Complete Care Guide

.jpg)

Ergonomic Design in Electric Toothbrushes: OEM Best Practices

How a Gentle senior brush protects Sensitive elderly gums

electric toothbrush heads Regular Clean

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Electric toothbrush heads Charcoal Infused-Diamond

Customization Teeth Whitening Gel

electric toothbrush heads Ultra Soft

Private Label Whitening Gel

electric toothbrush heads Charcoal Infuse-Round

electric toothbrush heads Deep Clean

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638