In today’s competitive market, ensuring product durability and consistent performance is essential for maintaining customer trust. Recently, manufacturers have raised concerns that UV Light Degradation may adversely affect the stability of formulations and packaging, potentially leading to Whitening Gel Leakage. In this blog, we explore the relationship between UV-induced material degradation and the resulting leakage issues, identify the key causes, and propose solutions to safeguard product quality.

As consumer expectations evolve, high-quality aesthetic and functional performance become non-negotiable factors for success. Products like whitening gels are expected not only to deliver effective results but also to maintain their integrity throughout their shelf life. Any defects—such as leakage from compromised packaging—can lead to costly recalls and diminished brand reputation. Therefore, understanding and mitigating factors like UV Light Degradation that could lead to Whitening Gel Leakage is essential for staying ahead in the marketplace.

UV Light Degradation refers to the breakdown of materials when exposed to ultraviolet radiation. This degradation can affect both the chemical and physical properties of polymers used in packaging and seals. Over time, UV exposure can cause discoloration, embrittlement, and loss of mechanical strength in components designed to keep the whitening gel contained. Recognizing these effects is crucial, especially for products marketed for their long-lasting stability.

Whitening Gel Leakage occurs when the gel escapes from its containment system due to compromised packaging integrity. Leakage may manifest as a complete rupture or gradual seepage, both of which significantly affect product efficacy and safety. Manufacturers have noted that when the packaging materials are degraded by UV exposure, micro-cracks and weakened seals develop, providing an escape route for the gel. This issue not only impacts the product’s aesthetic appeal but can also disrupt dosing accuracy and overall performance.

Several factors converge to create an environment where UV Light Degradation can lead to Whitening Gel Leakage:

Understanding these factors can help in developing a holistic strategy for mitigating leakage issues.

To combat the challenges posed by UV Light Degradation and to prevent Whitening Gel Leakage, manufacturers can adopt several strategies:

By integrating these measures, manufacturers can significantly reduce the risk of leakage while safeguarding the overall quality of whitening gel products.

Looking forward, the convergence of advanced material science, smart manufacturing, and improved regulatory standards will play a pivotal role in addressing issues related to UV Light Degradation and Whitening Gel Leakage. Innovations such as nanoscale coatings, real-time degradation monitoring, and AI-driven predictive maintenance are poised to transform product reliability. As consumer demand for high-performance aesthetic products continues to rise, companies that invest in such technologies will not only meet but exceed market expectations, establishing a competitive edge in global markets.

Conclusion

The relationship between UV Light Degradation and Whitening Gel Leakage underscores a critical challenge in product packaging and longevity. By understanding the underlying causes, enhancing material selection, optimizing design, and implementing robust quality control practices, manufacturers can effectively mitigate these risks. Continuous innovation and collaboration across the supply chain will be key to ensuring long-term product integrity and consumer satisfaction.

Interested in discovering how advanced packaging solutions can protect your products from UV damage? Contact us today to learn more about our tailored strategies and cutting-edge technologies.

Teeth whitening device OEM: In-Depth Cooperation Model from LOGO to Light Wave Customization

5 Signs You Need to Replace Your Electric Toothbrush: Insights from an OEM Factory

New Trends in the Electric Toothbrush Industry: How Can Intelligent Connectivity Enable Brand Premium?

Global Electric Toothbrush Market Report: Portrait of the Fastest Growing Regions and Consumer Groups

Create Your Brand: From “Make Your Own” to Professional Teeth Whitening Products

Do At-Home Light Therapy Teeth Whiteners Really Work?

Future Trends of Electric Toothbrush Production: Intelligent, Environmentally Friendly, and Core Competitiveness Enhancement

.jpg)

Can a Kids Electric Toothbrush OEM Serve the Dental Clinic Electric Toothbrush Market with Adaptive Designs?

Pros and Cons of Silicone Electric Toothbrushes

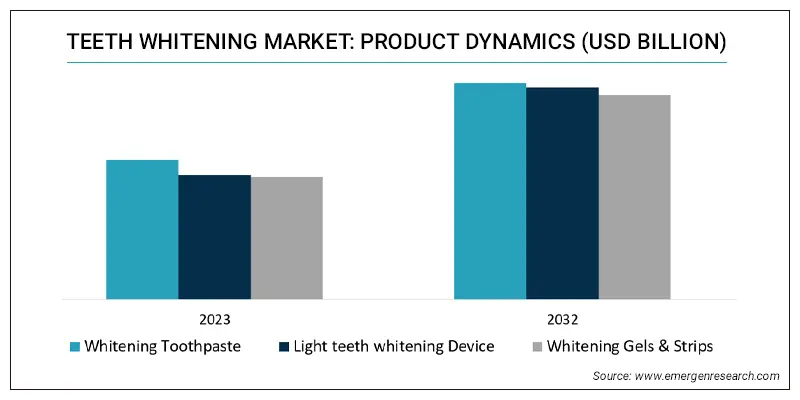

Trends in Electric Toothbrush Market

Electric Toothbrush Manufacturing: Key Resources and Supply Chain Insights for Brands

Analysis of the Core Components of the Electric Toothbrush: Technical Secrets from the Motor to the Brush Head

.jpg)

Executive Diwali gift or Status symbol toothbrush — what truly impresses?

.jpg)

Why an oil worker toothbrush is an essential part of Texas worker dental safety?

How Can a Magnetic Levitation Motor Supplier Enhance Collaboration with an OEM Sonic Toothbrush Manufacturer?

How to choose a qualified oral irrigator manufacturer?