As the demand for at-home oral care products grows rapidly, more brands are investing in the private mold development of innovative teeth whitening devices. Among them, red and blue light whitening devices have become a popular segment due to their dual-functionality in whitening and soothing gums. For any teeth whitening device manufacturer, creating a private model that stands out requires precision in two key aspects: the selection of shell materials and adherence to ergonomic design principles. In this blog, we will explore the key considerations in these areas and how they contribute to the product’s performance, user experience, and market competitiveness.

The choice of material for the outer shell of the teeth whitening device is critical. Most top-tier manufacturers prefer medical grade ABS material because of its excellent balance of biocompatibility, chemical resistance, and strength. Here’s why:

Ergonomic design is not just about comfort—it’s about maximizing user adoption and treatment effectiveness. When planning the private mold development of a red and blue light whitening device, manufacturers should focus on:

To succeed in private mold development, working with an experienced teeth whitening device manufacturer is essential. Look for partners with the following competencies:

In the competitive landscape of oral beauty products, developing a custom red and blue light teeth whitening device with premium material and ergonomic design is a proven way to build brand value. Partnering with a qualified teeth whitening device manufacturer ensures that your private mold development journey is efficient, compliant, and future-ready.

Optimizing the teeth whitening device production cycle: How Can Professional Manufacturers Shorten Delivery Time?

How to Choose a High-Quality LED Light Source for teeth Whitening Device? Factory Material Selection and Testing Standards

Case Study of Intelligent Upgrading of Dental Instrument Factory

Dentistry Instrument Factory Market Trends and Customized Production Solutions

.jpg)

Portable LED Teeth Whitening Kit OEM

Are the effects of cold light teeth whitening permanent?

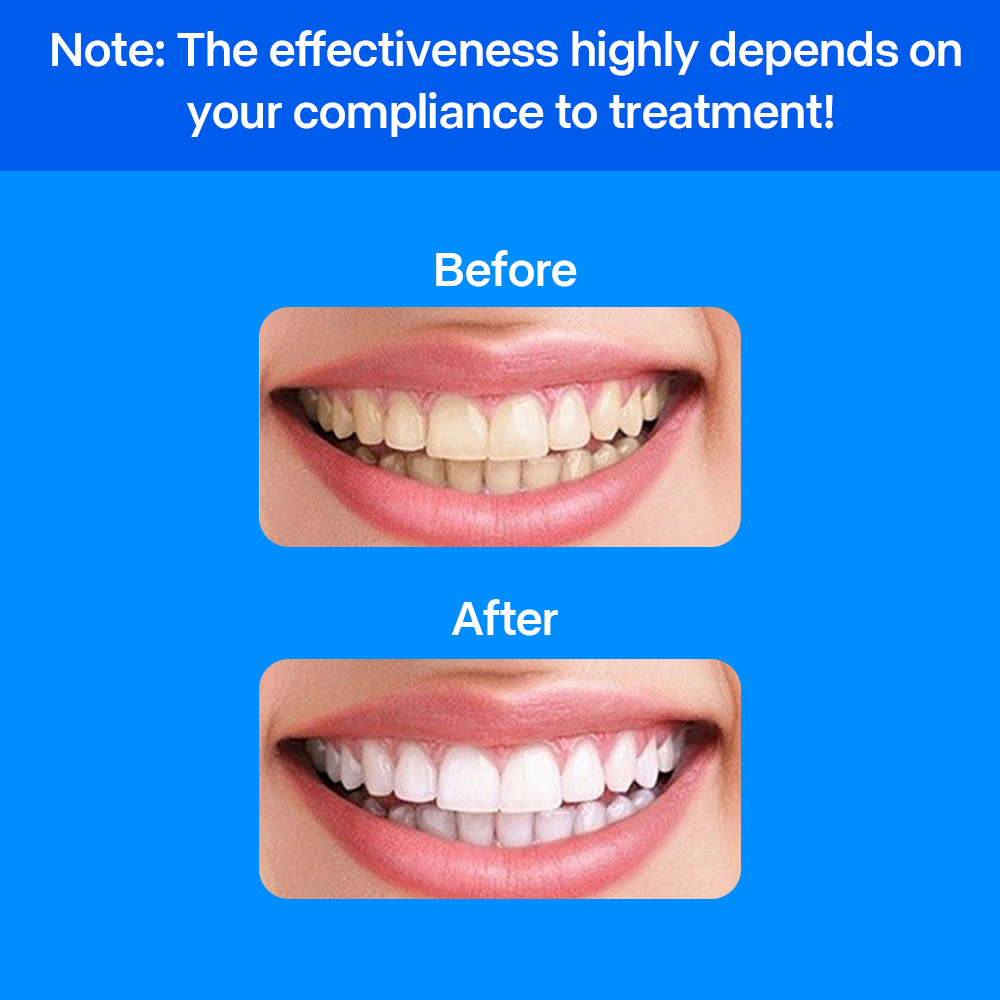

Clinical Results: Effectiveness of Home Teeth Whitening Device results

.jpg)

Wireless Inductive Charging Polishing Electric Toothbrush manufacturers

.jpg)

LED teeth whitening device manufacturer | Professional Whitening Device OEM Factory

The Truth About Blue Light Whitening in OEM Electric Toothbrushes

How Does Advanced Whitening Gel Formulation Cater to Sensitive Teeth Whitening Needs?

Do LED teeth whitening device trays need to be removed and cleaned frequently?

How Wireless Tech is Revolutionizing Oral Care Devices

Professional vs. Home Use: Key Technical Differences in Teeth Whitening Blue Lights

How Often Should I Use a LED Teeth Whitening Light? A Manufacturer’s Guide

The Science of Light: How Red & Blue LED Technology Enhances Modern Oral Care