In the fast-growing oral care market, choosing the right electric toothbrush factory can be the difference between product success and failure. For brand owners and sourcing managers, understanding how to properly evaluate an electric toothbrush factory is essential to ensure product consistency, timely delivery, and long-term partnership success. This article outlines a six-part evaluation framework to help you assess a factory’s comprehensive capabilities, including their OEM capabilities, manufacturing standards, and commitment to Electric Toothbrush Quality Manufacturing.

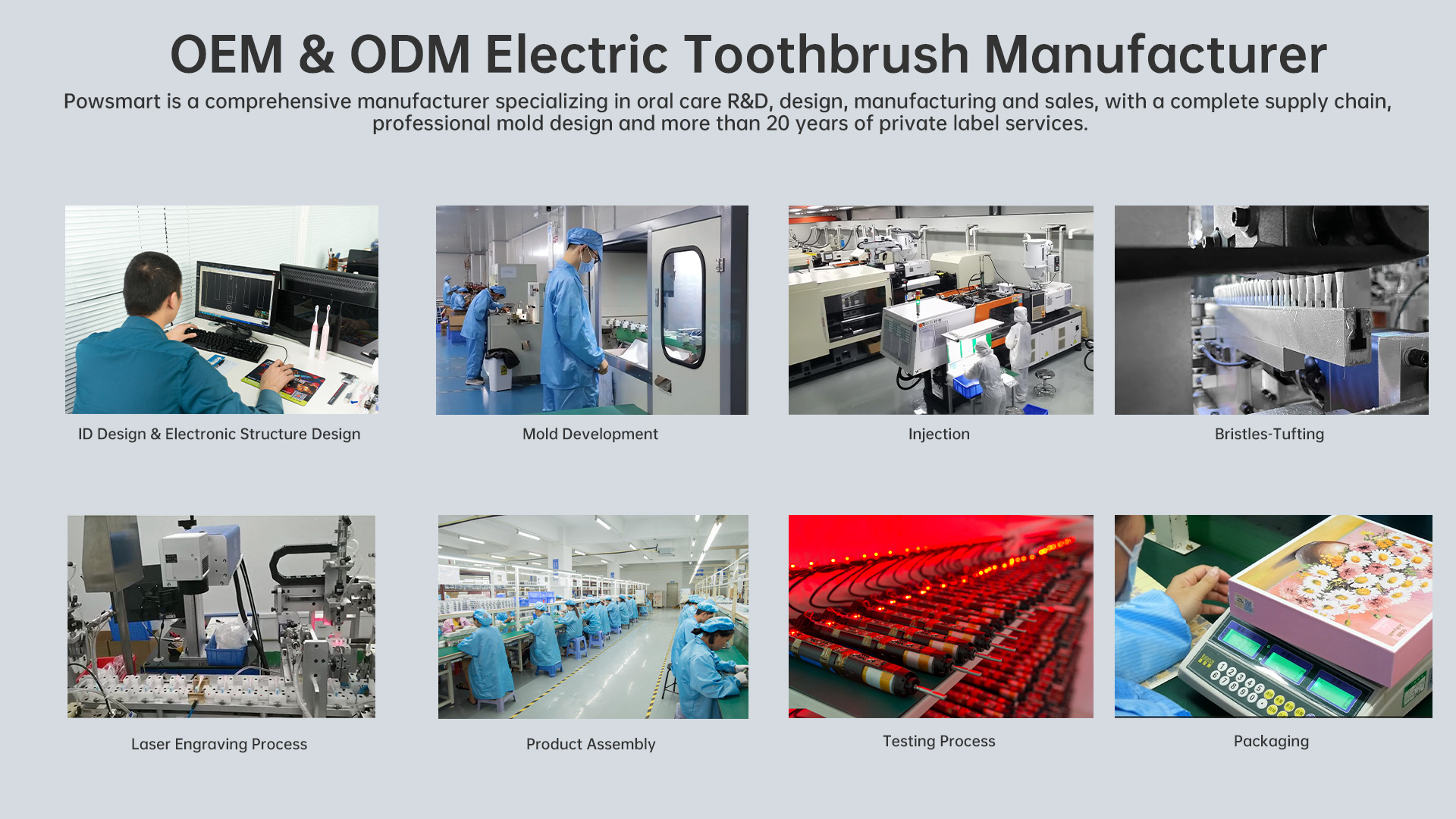

The first step in evaluating an electric toothbrush supplier is to investigate its core production competencies. A capable electric toothbrush factory should have:

In-house facilities for plastic injection molding, PCB assembly, and motor integration.

Experience with multiple product lines (oscillating, sonic, kids’ models).

Scalable production capacity that aligns with your demand projections.

This baseline assessment ensures the factory has the technical resources to meet your product specifications under various volumes.

Many oral care brands seek manufacturers that can provide OEM capabilities and even ODM (Original Design Manufacturing) services. During the evaluation, ask:

Can the factory customize molds, packaging, and firmware?

Do they offer product design support or only manufacturing?

Are there R&D engineers on-site for product development or improvement?

Strong OEM capabilities allow your brand to differentiate in a competitive marketplace while maintaining control over the product experience.

Reliable factories adhere to international manufacturing standards that ensure consistency, safety, and traceability. Key credentials to look for include:

ISO 9001 (quality management systems)

ISO 13485 (for medical-grade or oral hygiene devices)

BSCI or SEDEX certifications (ethical working conditions)

CE, FDA, or RoHS compliance for the products

These certifications are not only crucial for Electric Toothbrush Quality Manufacturing, but also for ensuring market entry compliance, especially in the EU and US.

Quality control is non-negotiable in oral care, where hygiene and performance are directly linked to consumer trust. Evaluate the factory’s approach to quality by checking:

Incoming material inspection protocols

In-process QC at every assembly stage

100% functional testing before packaging

Availability of quality documentation (e.g., IQC, IPQC, OQC reports)

Ask to review recent inspection reports or witness on-site quality testing during a factory audit or virtual tour.

A factory’s innovation culture reveals its long-term competitiveness. When evaluating an electric toothbrush factory, consider:

Do they invest in motor innovation, battery efficiency, or waterproofing tech?

Are they working on app-connected or smart toothbrush solutions?

How quickly can they iterate prototypes based on market feedback?

Factories that invest in R&D contribute to your brand’s ability to stay ahead of oral care trends and support a roadmap of future product launches.

Lastly, strong comprehensive capabilities include communication transparency and supply chain management. Check:

Do they provide fast response times and clear project timelines?

Can they manage fluctuating material costs and lead times?

Do they offer support with certifications, logistics, or after-sales services?

Smooth communication and a robust supply chain are critical to reduce risk, especially during high seasons or global disruptions.

In summary, to evaluate an electric toothbrush factory’s comprehensive capabilities, you must look beyond price. Investigate their OEM capabilities, adherence to manufacturing standards, approach to quality control, and long-term innovation plans. Only factories with proven Electric Toothbrush Quality Manufacturing practices and scalable processes can help you maintain product quality and grow your brand sustainably.

As a brand owner, choosing the right manufacturing partner is one of the most strategic decisions you’ll make. Use this selection guide as your framework—and build your supply chain on a foundation of trust, quality, and capability.

Maximizing Profit Margins: How to Position Water Flossers as Premium Products

.jpg)

Small Batch Electric Toothbrush OEM for Flexible B2B Brands

.jpg)

Wholesale Smart Electric Toothbrush Factory | Bulk Supplier

.jpg)

Power Toothbrush Process Optimization: Achieve 50% Faster Cleaning with Smart Brushing Algorithms

.jpg)

Which Product Functions and Performances of Water Flossers Are Users Most Concerned About?

Should a Custom Teeth Tray Include a Professional Teeth Shade Guide?

.jpg)

Electric Toothbrush Wholesale Supplier for Global B2B Distribution

OEM Customization Solution for Water Flossers: Engineering Parameters Such as Water Tank Capacity, Nozzle Type, and Pressure Setting

.jpg)

Clinical Strength Electric Toothbrush Colaba Clinic

.jpg)

Smart Timer Toothbrush Wholesale for Distributors & OEM Buyers

What Packaging Options Are Available for Custom Whitening Gel Products?

Strategies for Optimizing Supply Chain Management in Electric Toothbrush Factories

.jpg)

Is a Quiet Electric Toothbrush Best for NYC Apartments?

How to Choose Professional Electric Toothbrush Factory Customization Service?

.jpg)

OEM Smart Toothbrush Manufacturer | Custom B2B Solutions for Global Brands

The Brush Head Was Shedding Bristles While Brushing My Teeth